Minimum Quantity 4

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The S608 Lock Washer is a specialized component manufactured by Cummins, a well-established name in the commercial truck industry. This Cummins part is designed for use in commercial trucks, where it plays a significant role in ensuring the integrity and reliability of fastening applications across various truck components.

Basic Concepts of Lock Washers

Lock washers are mechanical devices used in fastening applications to prevent the loosening of fasteners due to vibration or other dynamic forces. They function by applying additional pressure to the fastener, creating friction that helps maintain the tightness of the connection. Lock washers come in various designs, including split lock washers, which have a gap that springs open when compressed, and serrated lock washers, which have teeth that dig into the surfaces they connect to enhance grip 1.

Purpose of the S608 Lock Washer

The S608 Lock Washer is specifically engineered to address the unique demands of commercial truck environments. It is utilized in various truck components where secure fastening is paramount. By preventing fastener loosening, the S608 Lock Washer contributes to the overall safety and efficiency of truck operations. Its application spans across critical truck components, ensuring that connections remain tight under the stress of heavy loads and dynamic driving conditions 2.

Key Features

The S608 Lock Washer is distinguished by several key features that enhance its functionality and durability. It is constructed from high-strength materials, ensuring it can withstand the rigors of commercial truck use. The design of the S608 includes specific elements that maximize its effectiveness in preventing fastener loosening, such as a precise spring tension that provides optimal pressure without compromising the integrity of the fastener or the surfaces it connects. Additionally, the S608 Lock Washer may feature unique attributes that differentiate it from standard lock washers, such as a specialized coating for enhanced corrosion resistance or a design that allows for easy installation and removal 3.

Benefits

Utilizing the S608 Lock Washer offers several advantages in commercial truck applications. It provides improved fastening security, ensuring that connections remain tight even under significant vibration and dynamic loads. This enhanced security contributes to the longevity of truck components by preventing wear and damage that can result from loose fasteners. Furthermore, the S608 Lock Washer’s design and material composition allow it to resist corrosion and maintain its effectiveness in the harsh operating conditions typical of commercial truck environments.

Troubleshooting and Maintenance

To ensure the longevity and effectiveness of the S608 Lock Washer, it is important to be aware of common issues that may arise, such as deformation or failure due to excessive stress or corrosion. Regular inspection of lock washers for signs of wear or damage is recommended. Maintenance practices should include the replacement of lock washers that show signs of deformation or failure to maintain secure fastening. Additionally, ensuring that fasteners are properly torqued can help prevent undue stress on lock washers and extend their service life.

Cummins Engine Compatibility with S608 Lock Washer

The S608 Lock Washer, manufactured by Cummins, is a critical component designed to ensure secure fastening in various engine applications. This part is integral to maintaining the integrity and performance of the engine systems it is used in. Below is a detailed description of how the S608 Lock Washer fits with the specified Cummins engines:

4B3.9, 6B5.9, 6C8.3, B3.9 G, G5.9, G855, G855 CM558

The S608 Lock Washer is compatible with the older generation engines such as the 4B3.9, 6B5.9, 6C8.3, B3.9 G, G5.9, G855, and G855 CM558. These engines, known for their robust design, benefit from the S608 Lock Washer in maintaining the stability of critical engine components.

GTA38 G CMEICS G116C, GTA855 CM558 (CM2358) G101, ISM CM570, ISM CM570/870

For the more advanced engines like the GTA38 G CMEICS G116C, GTA855 CM558 (CM2358) G101, ISM CM570, and ISM CM570/870, the S608 Lock Washer ensures that the fastenings remain tight and secure under high operational stresses. This is crucial for maintaining the precision and reliability of these engines.

ISX CM570, ISX CM870, ISX CM871, ISX15 CM2250, ISX15 CM2250 SN, ISX15 CM2350 X101

The ISX series engines, including the ISX CM570, ISX CM870, ISX CM871, ISX15 CM2250, ISX15 CM2250 SN, and ISX15 CM2350 X101, are designed for high performance and efficiency. The S608 Lock Washer plays a vital role in these engines by providing a dependable locking mechanism that prevents loosening due to vibrations and thermal expansion.

K19, K38, K50, KTA19GC, KTA19GC CM558, KTA38GC CM558

The K series engines such as the K19, K38, K50, KTA19GC, KTA19GC CM558, and KTA38GC CM558 also rely on the S608 Lock Washer. This part is essential for maintaining the structural integrity of these engines, ensuring that all fastened components remain securely in place.

L10 GAS, L10 MECHANICAL

The L10 engines, both GAS and MECHANICAL variants, utilize the S608 Lock Washer to maintain the precision and reliability of their fastenings. This is particularly important in these engines, where even minor loosening can lead to significant performance issues.

In summary, the S608 Lock Washer is a versatile and essential component that ensures the secure fastening of various engine parts across a wide range of Cummins engines. Its application across different engine models underscores its importance in maintaining the overall performance and longevity of these engines.

Role of Part S608 Lock Washer in Engine Systems

The S608 Lock Washer is an essential component in various engine systems, ensuring the stability and integrity of connections and mountings. Here’s how it integrates with several key components:

Air Inlet Connection

In the air inlet connection, the S608 Lock Washer prevents loosening of the fasteners that secure the air inlet to the engine, maintaining a consistent airflow and preventing potential air leaks.

Bypass Filter Mounting

For the bypass filter mounting, the lock washer ensures that the filter remains securely attached to the engine, which is vital for maintaining the filtration efficiency and preventing bypass scenarios that could harm the engine.

Connection Heat Exchanger

When connecting the heat exchanger, the S608 Lock Washer plays a role in keeping the connection tight, ensuring efficient heat transfer and preventing coolant leaks that could lead to engine overheating.

Corrosion Resistant Bracket

In corrosion-resistant brackets used throughout the engine, the lock washer helps maintain the integrity of the bracket’s attachment points, ensuring long-term durability in harsh environments.

Drive Ring Gear

For the drive ring gear, the lock washer secures the gear in place, which is important for the consistent operation of the gear system and the prevention of gear slippage.

Exhaust Manifold

In the exhaust manifold, the lock washer ensures that the manifold remains firmly attached to the engine, preventing exhaust leaks that could affect engine performance and emissions.

Fan Mounting Hub

The fan mounting hub relies on the S608 Lock Washer to keep the fan securely attached, ensuring efficient cooling and preventing the fan from becoming loose during operation.

Flywheel Housing Mounting Support

For the flywheel housing mounting support, the lock washer ensures that the housing remains securely mounted, which is essential for the smooth operation of the flywheel and clutch system.

Front Engine Arrangement

In the front engine arrangement, the lock washer secures various components, ensuring that the engine’s front-end remains stable and aligned, which is crucial for overall engine balance and performance.

Kit 4-14 Inch #1 Clutch Housing

Within the kit for the 4-14 inch #1 clutch housing, the lock washer ensures that the clutch housing remains securely fastened, which is important for the reliable engagement and disengagement of the clutch.

Lifting and Turbocharger Bracket

For the lifting and turbocharger bracket, the lock washer ensures that the turbocharger remains securely mounted, which is vital for maintaining turbocharger efficiency and preventing damage during engine operation.

Middle Exhaust Manifold Mounting

In the middle exhaust manifold mounting, the lock washer secures the manifold, ensuring efficient exhaust flow and preventing leaks that could affect engine performance.

Mounting Connection Aftercooler

The mounting connection for the aftercooler relies on the lock washer to keep the aftercooler securely attached, which is important for maintaining the efficiency of the cooling process and preventing leaks.

Mounting Fan and Spacer

For the mounting fan and spacer, the lock washer ensures that the fan remains securely in place, which is essential for maintaining efficient engine cooling.

Torque Converter Cooler

In the torque converter cooler, the lock washer secures the connections, ensuring efficient cooling of the torque converter fluid and preventing leaks that could lead to converter failure.

Conclusion

The S608 Lock Washer is a critical component in the maintenance and operation of commercial trucks and Cummins engines. Its design and functionality ensure secure fastening across a variety of applications, contributing to the safety, efficiency, and longevity of truck and engine components. Regular maintenance and proper use of this part are essential to maximize its benefits and ensure the reliability of fastening applications in demanding environments.

SPECIFICATIONS

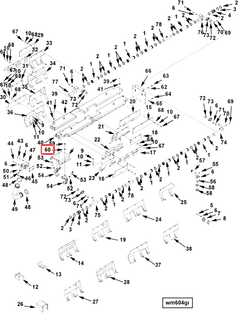

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.