This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The S610 Lock Washer is a specialized component manufactured by Cummins, a prominent name in the commercial vehicle industry. This part is designed for use in commercial trucks, where it plays a significant role in ensuring the integrity and reliability of fastening systems. Cummins is renowned for its high-quality parts and systems, and the S610 Lock Washer is no exception, offering robust performance in demanding truck applications.

Basic Concepts of Lock Washers

Lock washers are mechanical devices used in fastening applications to prevent screws and bolts from loosening due to vibration or other dynamic forces. They achieve this by applying additional pressure to the fastened components or by creating a spring-like tension that resists movement. Lock washers come in various designs, including split lock washers, which have a gap that creates tension when the washer is compressed, and serrated lock washers, which dig into the surfaces they are between to create friction 1.

Purpose of the S610 Lock Washer in Truck Operation

In the operation and maintenance of commercial trucks, the S610 Lock Washer serves a vital function by enhancing the security of bolted connections. It is applied in various truck components where vibrations and dynamic loads are common, such as in the engine, transmission, and chassis. By preventing bolts and screws from loosening, the S610 Lock Washer contributes to the overall safety and reliability of the truck, ensuring that critical components remain securely fastened during operation 2.

Key Features of the S610 Lock Washer

The S610 Lock Washer is characterized by its specific design and material properties that are tailored for heavy-duty applications. It is typically made from high-strength steel, which provides the necessary durability and resistance to wear and tear. The washer’s design may include features such as a split or serrated edge, which enhances its locking capability by increasing friction or applying tension to the fastened components. These features ensure that the S610 Lock Washer can withstand the rigors of commercial truck use 3.

Benefits of Using the S610 Lock Washer

The use of the S610 Lock Washer offers several advantages in commercial truck applications. It provides improved fastening security, which is crucial in environments where vibrations and dynamic loads are prevalent. The washer’s design helps to resist loosening, ensuring that bolted connections remain tight and secure. Additionally, the S610 Lock Washer is known for its longevity, offering reliable performance over extended periods, even in demanding conditions.

Installation Guidelines

Proper installation of the S610 Lock Washer is key to ensuring its optimal performance and safety. It should be placed under the head of the bolt or screw, with the split or serrated edge facing the surface to be fastened. Care should be taken to ensure that the washer is not damaged during installation, as this could compromise its locking capability. The bolt or screw should be tightened to the manufacturer’s specified torque to ensure a secure connection without over-tightening, which could lead to damage 4.

Troubleshooting Common Issues

Common issues with lock washers, such as failure to prevent loosening, can often be traced back to improper installation or selection of an inappropriate washer for the application. To address these issues, it is important to ensure that the correct type and size of lock washer are used and that it is installed correctly. Regular inspection of lock washers can help identify wear or damage that may affect their performance, allowing for timely replacement.

Maintenance Tips

Regular inspection and maintenance of lock washers are recommended to prolong their service life and ensure continued reliable operation. This includes checking for signs of wear, corrosion, or damage and replacing washers as necessary. Additionally, ensuring that bolts and screws are properly torqued and that fastening systems are free from excessive vibration can help maintain the effectiveness of lock washers.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial vehicle industry for producing high-quality, reliable components and systems. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial and industrial applications.

Lock Washer S610 Compatibility with Cummins Engines

The Lock Washer S610, manufactured by Cummins, is a critical component that ensures secure fastening in various engine applications. This part is designed to work seamlessly with a range of Cummins engines, providing stability and reliability in demanding environments.

Group 1: 4B3.9, 6B5.9, 6C8.3, B5.9 G, G8.3, G855, G855 CM558, GTA38 G CMEICS G116C, GTA855 CM558 (CM2358) G101

The S610 is compatible with several high-performance and industrial engines within this group. These engines, known for their robust design and efficiency, benefit from the added security that the S610 provides. The washer’s precision engineering ensures that it fits perfectly, preventing loosening and maintaining the integrity of the fastening.

Group 2: ISBE CM2150, ISBE4 CM850, ISM CM570, ISM CM570/870, ISM CM876, ISM11 CM876 SN

In this group, the S610 is tailored to fit the specific needs of the ISBE and ISM series engines. These engines are widely used in various applications, from construction to marine, and the S610 washer ensures that all components remain securely fastened, enhancing the overall performance and longevity of the engine.

Group 3: K19, K38, K50

The K-series engines, including the K19, K38, and K50, are designed for heavy-duty applications. The S610 is engineered to withstand the rigors of these demanding environments, providing a reliable locking mechanism that prevents wear and tear, ensuring the engine operates at peak efficiency.

Group 4: KTA19GC, KTA19GC CM558, KTA38GC CM558

These gas-powered engines are used in a variety of applications, from power generation to industrial use. The S610 is an essential component in these engines, offering the necessary security for critical fastenings. Its design ensures that the washer can handle the unique stresses and conditions of gas engine operations.

Group 5: L10 CELECT, L10 GAS, L10 MECHANICAL

The L10 series engines, available in CELECT, GAS, and MECHANICAL variants, benefit from the S610. This washer is crucial for maintaining the structural integrity of these engines, ensuring that all parts remain securely fastened, even under high-stress conditions.

Group 6: M11 CELECT

The M11 CELECT engine, known for its efficiency and reliability, is another beneficiary of the S610. This washer provides the necessary security for the engine’s components, ensuring that the engine operates smoothly and efficiently, with all parts remaining firmly in place.

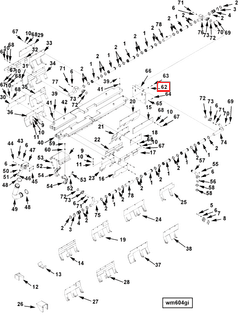

Role of Part S610 Lock Washer in Engine Systems

The S610 Lock Washer is an essential component in ensuring the secure attachment and stability of various engine system components. Its application spans across multiple subsystems, contributing to the overall integrity and performance of the engine.

Accessory Plate and Auxiliary Systems

In the accessory plate assembly, the S610 is used to secure bolts that attach the plate to the engine block. This ensures that accessories such as the fuel control module and fuel transfer tank remain firmly in place, preventing any misalignment that could lead to operational issues.

Cooling and Plumbing Systems

For the auxiliary cooling plumbing and coolant heater plumbing, the S610 plays a significant role in maintaining the tightness of connections. It is employed in the cooler, torque converter mounting, and EBM (Engine-driven Blower Motor) plumbing to prevent loosening due to vibrations, ensuring consistent coolant flow and temperature regulation.

Structural and Mounting Components

In the block short kit and front cover assembly, the S610 is critical for securing bolts that hold these components to the engine block. This stability is vital for the structural integrity of the engine, especially under high-stress conditions.

Fuel System Components

Within the fuel system, the S610 is used in the fuel and water-wash governor pump, fuel control module, and fuel transfer tank. It ensures that all connections remain secure, which is essential for maintaining fuel pressure and preventing leaks.

Oil and Lubrication Systems

For the lubrication system, the S610 is applied in the oil pan adapter and remote-mounted oil filter. This ensures that oil lines and filters are securely attached, maintaining proper lubrication and preventing oil leaks.

Drive and Mechanical Components

In the EBM drive and pulley and belt guard assembly, the S610 secures bolts that attach these components, ensuring they remain in place despite the dynamic forces at play. This is particularly important for the fan guard and fan hub bracket, where secure attachment is necessary to protect surrounding components from damage.

Miscellaneous Applications

The S610 is also utilized in the idler pulley kit, manual control, and shipping bracket mounting. These applications ensure that all mechanical components remain securely fastened, contributing to the overall reliability and performance of the engine system.

Conclusion

The S610 Lock Washer is a critical component in the maintenance and operation of commercial trucks and Cummins engines. Its design and material properties are tailored for heavy-duty applications, providing the necessary durability and resistance to wear and tear. By ensuring secure fastening in various engine systems, the S610 contributes to the overall safety, reliability, and performance of the vehicle. Proper installation, regular maintenance, and timely replacement of this part are essential for maintaining the integrity of fastening systems in demanding environments.

-

Tyre and Vehicle Dynamics, Hans B. Pacejka, Butterworth-Heinemann, 2006

↩ -

Motor Vehicle Mechanics Textbook, Fifth Edition, F. K. Sully, Heinemann Professional Publishing, 1998

↩ -

Pistons and Engine Testing, Wolf-Henning Schneider, Springer Nature, 2016

↩ -

General Information, Bulletin Number 4021428, Operation and Maintenance Manual

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.