S640

Plain Washer

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins S640 Plain Washer is a critical component in commercial truck applications, ensuring the integrity of various assemblies through proper load distribution, alignment, and spacing. Its role is vital in heavy-duty truck operations, where reliability and durability are essential.

Basic Concepts of Plain Washers

Plain washers are fundamental components in mechanical systems, serving multiple functions such as distributing loads, preventing component damage, and maintaining proper spacing and alignment. By increasing the contact area between parts, plain washers reduce pressure per unit area, preventing surface damage and ensuring even force distribution 1.

Role of the S640 Plain Washer in Truck Operation

In commercial trucks, the S640 Plain Washer is integral to fastening systems, aiding in the even distribution of clamping forces. This ensures the durability and reliability of truck components by spreading force over a larger area, preventing surface damage, and contributing to assembly stability 2.

Key Features

The S640 Plain Washer is designed for heavy-duty applications, featuring a material composition resistant to wear and deformation. Its dimensions are tailored for specific applications, with unique characteristics like specific thickness or outer diameter enhancing performance and longevity in demanding environments 3.

Benefits

Using the S640 Plain Washer enhances load distribution, crucial in heavy-duty applications under significant stress. It prevents galling and seizing between surfaces, reduces stress concentrations at contact points, and contributes to the longevity of components. Overall, this Cummins part ensures the efficiency and safety of truck operations by maintaining reliable fastening systems over time.

Troubleshooting and Maintenance

Common issues with plain washers include wear, deformation, or failure due to excessive load or environmental factors. Regular inspection and maintenance are vital to identify these issues early. Replacing worn or damaged washers ensures optimal performance of truck components. Proper maintenance practices, including using the correct washers for specific applications, can prevent issues and extend the lifespan of both washers and supported components.

About Cummins

Cummins Inc. is renowned for its diesel engines and related technologies, with a history of innovation and expertise in the field. The company is committed to providing high-quality components for the commercial trucking industry. Products like the S640 Plain Washer reflect Cummins’ focus on reliability, performance, and durability, supporting the needs of the commercial trucking sector.

Cummins S640 Plain Washer Compatibility

The Cummins S640 Plain Washer is compatible with a variety of Cummins engines, ensuring a secure seal and preventing leaks in various applications. Below is a detailed look at the engines compatible with this part:

Cummins 6C Series Engines

- 6C8.3

Cummins G Series Engines

- G8.3

- G855

- G855 CM2150 MCRS

Cummins K Series Engines

- K19

- K38

- K50

Cummins KTA19 Series Engines

- KTA19GC

- KTA19GC CM558

Cummins N14 Series Engines

- N14 G

- N14 MECHANICAL

Cummins QSK Series Engines

- QSK19 CM2350 K114

- QSK19 CM2350 K144G

- QSK19 CM500

- QSK19 CM850 MCRS

- QSK19G

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

- QSK45 CM500

- QSK50 CM2150 K107

Cummins QSB Series Engines

- QSB7 CM2880 B117

Cummins ISX Series Engines

- ISX CM570

Cummins NH/NT Series Engines

- NH/NT 855

Using the correct washer for each specific engine model is crucial to maintain the integrity of sealing systems and prevent potential leaks.

Role of the S640 Plain Washer in Engine Systems

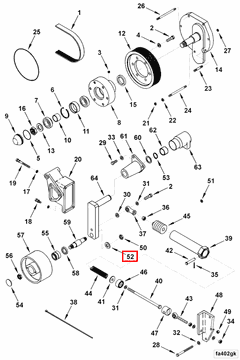

The S640 Plain Washer is essential in various engine systems, providing necessary support and functionality across multiple applications. Here’s how it integrates with different engine components:

Accessories and Accessory Drive

The S640 Plain Washer ensures smooth operation and reduces friction between rotating parts in accessory systems, maintaining proper alignment and spacing within the accessory drive for efficient power transfer to accessories like the alternator and water pump.

Alternator Mounting

For alternator mounting, this Cummins part secures the alternator to the engine block or bracket, ensuring firm placement without excessive vibration, which could lead to inefficient power generation and potential damage.

Vibration Isolation

In vibration isolation systems, the S640 Plain Washer separates moving parts and reduces vibration transmission. This is crucial in isolator vibration kits and other vibration mounting isolators, minimizing engine vibrations for performance and longevity.

Drive Arrangement and Fan

Within the drive arrangement fan system, the S640 Plain Washer maintains correct spacing between the fan and its mounting bracket, ensuring efficient fan operation without undue stress on the drive mechanism, contributing to effective engine cooling.

Engine Water Inlet Mounting and Exhaust Connection Bracket

For engine water inlet mounting and exhaust connection brackets, the S640 Plain Washer secures these components to the engine block, ensuring a tight and leak-free connection critical for proper cooling and exhaust system functioning.

Expansion Jacket Water Tank and Front Engine Support

In the expansion jacket water tank and front engine support, the S640 Plain Washer maintains structural integrity and alignment, preventing undue stress or movement that could compromise system effectiveness.

Harness and Wiring

In electrical systems involving harness and wiring, the S640 Plain Washer secures wires and cables, preventing chafing against moving parts and ensuring a reliable electrical connection.

Heat Exchanger Kit and Mounting Heat Shield

For heat exchanger kits and mounting heat shields, the S640 Plain Washer secures these components, ensuring they remain in the correct position to effectively manage engine temperatures.

Plumbing and Fuel Supply

In plumbing and fuel supply systems, the S640 Plain Washer ensures tight connections between pipes and fittings, preventing leaks and ensuring a consistent fuel supply to the engine.

Pump and Raw Water Systems

For pumps and raw water systems, the S640 Plain Washer maintains proper seals and connections, ensuring efficient pump operation and consistent water flow.

Radiator Cooling and Engine Monitoring Systems

In radiator cooling systems and engine monitoring systems, the S640 Plain Washer secures sensors and other components, ensuring they remain in the correct position for accurate readings and effective cooling.

Rear Engine Support and Marine Gear Supports

Finally, in rear engine support and marine gear supports, the S640 Plain Washer ensures these components are securely mounted, providing stability and reducing the risk of damage from engine vibrations.

Conclusion

The Cummins S640 Plain Washer is a versatile and essential component in commercial truck and engine applications. Its role in ensuring proper load distribution, alignment, and spacing contributes significantly to the reliability and durability of truck and engine components. Regular maintenance and the use of correct washers for specific applications are crucial for optimal performance and longevity.

-

Osgood, L., Cameron, G., & Christensen, E. (2024). Engineering Mechanics: Statics. Creative Commons.

↩ -

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩ -

Cummins Inc. (n.d.). QSM11 Marine, Bulletin Number 4021940, Operation and Maintenance Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.