3287561

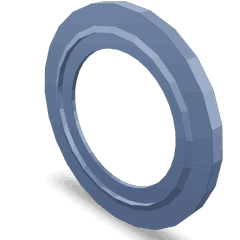

Sealing Washer

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 2

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Sealing Washer 3287561 by Cummins is a critical component designed to maintain the integrity and efficiency of mechanical systems in commercial trucks. Its primary function is to provide a secure seal between components, preventing leaks and ensuring system reliability. This part is essential for the efficient and safe operation of various truck systems.

Basic Concepts of Sealing Washers

Sealing washers are vital components in mechanical systems, designed to create a seal between two or more parts. They prevent the escape of fluids or gases by filling the gap between surfaces. Typically made from materials that can withstand pressure, temperature variations, and chemical exposure, these washers are used in engines, transmissions, and hydraulic systems where maintaining a seal is crucial for operation 1.

Role of Sealing Washer 3287561 in Truck Operation

The Sealing Washer 3287561 is specifically designed for commercial trucks, ensuring a secure seal in areas prone to leaks, such as between flanges or around bolts in fluid systems. Its interaction with other components helps contain fluids or gases within the system, contributing to the overall efficiency and safety of the truck’s operation 2.

Key Features

This Cummins part is characterized by several key features that enhance its performance. It is made from durable materials capable of withstanding the pressures and temperatures encountered in truck operations. The design allows it to conform to the surfaces it seals, ensuring a tight fit. Additionally, it may possess unique attributes such as resistance to certain chemicals or the ability to operate in extreme conditions, further enhancing its effectiveness in commercial truck applications 3.

Benefits

The use of the Sealing Washer 3287561 in truck operations offers several benefits. It contributes to improved efficiency by ensuring that fluids or gases remain within the system, reducing the need for frequent maintenance or repairs. Its durability and reliability mean that it can withstand the rigors of commercial truck use, providing long-term performance. Furthermore, by preventing leaks, it helps maintain the integrity of the truck’s mechanical systems, enhancing overall operational reliability 4.

Troubleshooting and Maintenance

Common issues with the Sealing Washer 3287561 may include wear and tear, deformation, or failure to create a proper seal. Troubleshooting these problems involves inspecting the washer for signs of damage or wear and ensuring that it is correctly installed. Maintenance practices to ensure the longevity and optimal performance of the washer include regular inspection and replacement as necessary. Additionally, ensuring that the surfaces it seals are clean and free from debris can help maintain an effective seal 5.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial truck operations. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry 6.

Role of Part 3287561 Sealing Washer in Engine Systems

The Sealing Washer 3287561 is integral to maintaining the integrity and efficiency of various engine systems. In the Accessory Drive system, it ensures that the seals between components are maintained, preventing lubricant leakage and ensuring smooth operation of the drive components.

Within the Complete Engine Gasket Kit and Full Engine Gasket Set, the Sealing Washer plays a significant role in creating a reliable seal between the Cylinder Head and the Engine Block. This is vital for maintaining compression and preventing coolant or oil leaks, which could lead to engine damage.

In the Drive, Rear Gear Train Accessory, the Sealing Washer is used to secure the seals around the gear housing, ensuring that lubricants remain contained and contaminants are kept out.

The Housing, Flywheel often incorporates Sealing Washers to maintain the seal between the flywheel and the engine block, which is essential for the proper functioning of the starting system and overall engine balance.

When dealing with the Long Block assembly, the Sealing Washer is employed in various joints and connections to ensure that the engine’s internal pressures are maintained and that fluids do not escape.

In the Lower Engine Gasket Kit and Lower Engine Gasket Set, the Sealing Washer is critical for sealing the Oil Pan to the engine block, ensuring that oil is retained within the lubrication system.

The Module, Engine Control may utilize Sealing Washers in its housing to protect sensitive electronic components from moisture and contaminants.

The Pan, Oil often requires Sealing Washers to ensure a tight seal with the engine block, preventing oil leaks which could lead to lubrication failure.

In the Power Take-Off Housing and Power Takeoff Housing, Sealing Washers are used to maintain seals at various connection points, ensuring that the power transfer is efficient and free from leaks.

The Threaded Assembly Plug often incorporates Sealing Washers to ensure a secure and leak-proof seal, which is essential in maintaining system integrity.

Lastly, in the Upper Engine Gasket Kit, Sealing Washers are used to ensure proper sealing around the Head, Cylinder, preventing any escape of combustion gases and maintaining engine efficiency.

Conclusion

The Sealing Washer 3287561 by Cummins is a vital component in the maintenance and operation of commercial truck engines. Its role in preventing leaks, ensuring system integrity, and contributing to the overall efficiency and safety of truck operations cannot be overstated. Regular maintenance and proper installation of this part are essential to ensure the longevity and reliability of the truck’s mechanical systems.

-

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5613072.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5613072.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5613072.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.