3963988

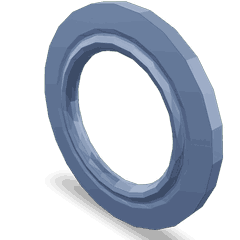

Sealing Washer

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 3

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

Sealing washers are critical components in the maintenance and operation of commercial trucks, ensuring the integrity of various mechanical systems. The 3963988 sealing washer by Cummins exemplifies this type of component. A sealing washer is a small, often overlooked part that plays a significant role in preventing leaks and maintaining system efficiency. It is designed to create a seal between two surfaces, typically where a fluid or gas is present, ensuring that these substances do not escape from their intended pathways.

Basic Concepts of Sealing Washers

Sealing washers are crafted from a variety of materials, including rubber, metal, and composite materials, depending on the specific application and environmental conditions they will face 1. Their design is straightforward yet effective, typically featuring a flat or slightly concave shape that conforms to the surfaces it seals against. The principle of operation for sealing washers involves compression; when tightened between two surfaces, the washer deforms slightly, filling any microscopic gaps and creating a barrier that prevents leaks. This mechanism is vital for maintaining the integrity of mechanical systems, ensuring that fluids and gases remain within their designated pathways 2.

Purpose of the 3963988 Sealing Washer

The 3963988 sealing washer by Cummins is designed to serve a specific function within the complex systems of a commercial truck. It is associated with components where fluid or gas sealing is required to ensure optimal operation. By providing a reliable seal, this washer contributes to the efficient functioning of these systems, preventing leaks that could lead to performance issues or safety hazards. Its role is particularly important in environments where the washer is exposed to high pressures, temperatures, or corrosive substances 3.

Key Features

The 3963988 sealing washer boasts several key features that enhance its performance and durability. Its material composition is selected to withstand the specific conditions it will encounter, ensuring longevity and reliability. The design specifications of this washer, including its thickness and outer diameter, are tailored to fit precisely within the systems it is intended for, providing an effective seal. Additionally, any unique attributes, such as resistance to certain chemicals or operating temperatures, further contribute to its effectiveness in demanding environments 4.

Benefits

Utilizing the 3963988 sealing washer offers several advantages. It contributes to improved system efficiency by ensuring that fluids and gases remain within their intended pathways, reducing the risk of leaks that could impair performance. The durability and reliability of this washer also mean that it can withstand the rigors of commercial truck operation, leading to longer intervals between maintenance checks and replacements. These benefits collectively contribute to the overall performance and maintenance efficiency of the truck, enhancing its reliability and operational lifespan.

Troubleshooting and Maintenance

Identifying common issues with sealing washers, such as leaks or signs of wear, is crucial for maintaining the efficiency and safety of a truck’s systems. Regular inspections of sealing washers, including the 3963988 model, are recommended to ensure they remain in good condition. Maintenance practices should include checking for any signs of damage or deformation and replacing washers as needed to prevent potential leaks. The importance of these practices cannot be overstated, as they help maintain the integrity of the systems the washers are a part of.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history in the diesel engine industry, Cummins has established itself as a provider of innovative and high-quality solutions for the commercial vehicle sector. The company’s commitment to quality and innovation is evident in its wide range of products, including the 3963988 sealing washer, which is designed to meet the demanding requirements of commercial truck applications.

Cummins Sealing Washer Part 3963988 Compatibility

The Cummins sealing washer part number 3963988 is a critical component used across a variety of Cummins engine models. This part is designed to provide a secure seal in various engine applications, ensuring that fluids and gases remain contained within the system. Below is a detailed breakdown of the engines with which this sealing washer is compatible:

Cummins 4B3.9 Engines

The 4B3.9 engine series benefits from the sealing washer 3963988, ensuring optimal performance and longevity by preventing leaks in critical areas.

Cummins 6B5.9 Engines

Similarly, the 6B5.9 engine series utilizes the sealing washer 3963988 to maintain system integrity and efficiency.

Cummins 6C8.3 Engines

The 6C8.3 engine series also incorporates the sealing washer 3963988, which is essential for maintaining the engine’s sealing requirements.

Cummins B4.5 CM2350 B129B Engines

The B4.5 CM2350 B129B engine series relies on the sealing washer 3963988 to ensure that all seals are properly maintained, preventing any potential leaks.

Cummins B6.7 CM2350 B135B Engines

The B6.7 CM2350 B135B engine series uses the sealing washer 3963988 to ensure that the engine’s sealing components are in top condition.

Cummins B6.7 CM2670 B153B Engines

The B6.7 CM2670 B153B engine series incorporates the sealing washer 3963988 to maintain the integrity of the engine’s sealing system.

Cummins B6.7 CM2670 B164C Engines

The B6.7 CM2670 B164C engine series also utilizes the sealing washer 3963988 to ensure that the engine’s seals are effective and reliable.

Cummins B6.7 G CMOH6.0 B125 Engines

The B6.7 G CMOH6.0 B125 engine series uses the sealing washer 3963988 to maintain the sealing integrity of the engine.

Cummins D4.0 CM2620 D103B Engines

The D4.0 CM2620 D103B engine series incorporates the sealing washer 3963988 to ensure that the engine’s sealing system is effective.

Cummins F3.8 CM2350 F120B Engines

The F3.8 CM2350 F120B engine series uses the sealing washer 3963988 to maintain the sealing integrity of the engine.

Cummins F3.8 CM2350 F128C Engines

The F3.8 CM2350 F128C engine series incorporates the sealing washer 3963988 to ensure that the engine’s seals are effective.

Cummins F3.8 CM2620 F137B Engines

The F3.8 CM2620 F137B engine series uses the sealing washer 3963988 to maintain the sealing integrity of the engine.

Cummins F3.8 F102 Engines

The F3.8 F102 engine series incorporates the sealing washer 3963988 to ensure that the engine’s seals are effective.

Cummins F4.5 CM2620 F139B Engines

The F4.5 CM2620 F139B engine series uses the sealing washer 3963988 to maintain the sealing integrity of the engine.

Cummins F4.5 CM2620 F141C Engines

The F4.5 CM2620 F141C engine series incorporates the sealing washer 3963988 to ensure that the engine’s seals are effective.

Cummins ISB (Chrysler) Engines

The ISB (Chrysler) engine series uses the sealing washer 3963988 to maintain the sealing integrity of the engine.

Cummins ISB CM2150 Engines

The ISB CM2150 engine series incorporates the sealing washer 3963988 to ensure that the engine’s seals are effective.

Cummins ISB CM550 Engines

The ISB CM550 engine series uses the sealing washer 3963988 to maintain the sealing integrity of the engine.

Cummins ISB CM850 Engines

The ISB CM850 engine series incorporates the sealing washer 3963988 to ensure that the engine’s seals are effective.

Cummins ISB/ISD4.5 CM2150 B119 Engines

The ISB/ISD4.5 CM2150 B119 engine series uses the sealing washer 3963988 to maintain the sealing integrity of the engine.

Cummins ISB/ISD6.7 CM2150 SN Engines

The ISB/ISD6.7 CM2150 SN engine series incorporates the sealing washer 3963988 to ensure that the engine’s seals are effective.

Cummins ISB3.9 CM2220 B107 Engines

The ISB3.9 CM2220 B107 engine series uses the sealing washer 3963988 to maintain the sealing integrity of the engine.

Cummins ISB4.5 CM2350 B104 Engines

The ISB4.5 CM2350 B104 engine series incorporates the sealing washer 3963988 to ensure that the engine’s seals are effective.

Cummins ISB5.9 CM2880 B110 Engines

The ISB5.9 CM2880 B110 engine series uses the sealing washer 3963988 to maintain the sealing integrity of the engine.

Cummins ISB5.9 CM2880 B127 Engines

The ISB5.9 CM2880 B127 engine series incorporates the sealing washer 3963988 to ensure that the engine’s seals are effective.

Role of Part 3963988 Sealing Washer in Engine Systems

The Part 3963988 Sealing Washer is integral to maintaining the integrity and efficiency of various engine systems. In the Auxiliary Cooling Plumbing, it ensures that coolant flows without leaks, preserving the cooling system’s effectiveness. At the Corrosion Resistor Location, it helps in preventing fluid seepage, thereby protecting the resistor from corrosive elements.

Within the Cylinder Head Gasket Kit and Cylinder Head Gasket Set, the sealing washer plays a part in maintaining the seal between the cylinder head and engine block, ensuring combustion gases do not escape. Similarly, in the Engine Coolant Vent, it prevents coolant loss, maintaining the proper coolant level for optimal engine temperature regulation.

In the Fluid Doser system, the sealing washer ensures precise dosing by preventing fluid leaks. The Flywheel Housing and Flywheel Housing Plumbing benefit from its use by maintaining a seal that prevents oil leaks, which is essential for the lubrication and cooling of the flywheel.

For the Fuel Drain Plumbing, Fuel Injection Pump, Fuel Inlet Fitting, Fuel Pump, Fuel Shutoff Valve, and Fuel Tube Kit, the sealing washer is vital in ensuring that fuel systems remain leak-free, which is important for the safe and efficient operation of the fuel delivery system.

In the Gasket Kit and Lower Engine Gasket Kit, the sealing washer contributes to the overall sealing strategy, preventing oil and coolant leaks that could lead to engine damage. The Oil Replenishing System relies on it to maintain seals around replenishment points, ensuring oil levels are consistently maintained.

The Parts Distribution Center Kit uses the sealing washer to ensure that fluid distribution within the kit is leak-free, maintaining the efficiency of the distribution system. In the Plain Hose Kit and Pressure Regular Valve Kit, it ensures that hoses and valves maintain their seals, preventing fluid loss and ensuring system pressure is maintained.

The Rear Gear Train Accessory Drive and Turbocharger Plumbing also utilize the sealing washer to prevent oil leaks, which is essential for the lubrication and cooling of these high-stress components. Lastly, in the Upper Engine Gasket Kit and Upper Gasket, it ensures that the upper sections of the engine maintain their seals, preventing gas and fluid leaks that could affect engine performance.

Conclusion

The 3963988 sealing washer by Cummins is a vital component in the maintenance and operation of commercial trucks. Its role in preventing leaks and maintaining system efficiency cannot be overstated. By understanding the basic concepts, purpose, key features, and benefits of this part, as well as its compatibility with various Cummins engine models, one can appreciate its importance in ensuring the reliability and longevity of commercial truck engines.

-

Lejda, K., & Wos, P. (2012). Internal Combustion Engines. InTech.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Isermann, R. (2017). Combustion Engine Diagnosis. Springer Vieweg.

↩ -

Happian-Smith, J. (2002). An Introduction to Modern Vehicle Design. Butterworth-Heinemann.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.