This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 202969 Water Pump Shaft is a component designed for use in commercial trucks. It plays a role in the engine cooling system by ensuring that the engine operates within optimal temperature ranges. This part is integral to the efficient functioning of the truck’s engine, contributing to its overall performance and longevity.

Basic Concepts of Water Pump Shafts

A water pump shaft is a fundamental component within the engine cooling system. Its primary function is to facilitate the rotation of the water pump impeller, which in turn circulates coolant throughout the engine. This circulation is vital for dissipating heat generated during engine operation, thereby maintaining stable engine temperatures and preventing overheating 1.

Purpose of the Cummins 202969 Water Pump Shaft

This Cummins part is specifically engineered to support the water pump’s operation in commercial trucks. By enabling the impeller to rotate, it ensures coolant is effectively circulated. This circulation helps maintain optimal engine temperature, which is important for the engine’s efficiency and durability. The shaft’s design contributes to the prevention of overheating, which can lead to engine damage and reduced performance 2.

Key Features

The Cummins 202969 Water Pump Shaft is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that are resistant to wear and corrosion, ensuring longevity in demanding operating conditions. The design of the shaft is optimized for smooth operation, reducing friction and the potential for mechanical failure. Additionally, it is engineered to withstand the high temperatures and pressures present in the engine cooling system 3.

Benefits

Utilizing the Cummins 202969 Water Pump Shaft offers several benefits. It contributes to improved engine efficiency by ensuring consistent coolant circulation, which helps maintain optimal engine temperatures. This consistent cooling reduces the risk of overheating, enhancing the engine’s reliability and performance. Furthermore, the durable construction of the shaft ensures it can withstand the rigors of commercial truck operation, providing long-term value and reliability.

Installation Process

Installing this part requires careful attention to detail to ensure proper function and longevity. The process involves removing the old shaft, inspecting the water pump and surrounding components for damage or wear, and then installing the new shaft. It is important to use the correct tools and follow manufacturer guidelines to ensure a secure and proper fit. Lubricating the shaft before installation can also help reduce friction and wear.

Common Issues and Troubleshooting

Common issues with the Cummins 202969 Water Pump Shaft may include wear, corrosion, or mechanical failure due to excessive heat or pressure. Symptoms of these issues can include engine overheating, coolant leaks, or unusual noises from the water pump. Troubleshooting these problems may involve inspecting the shaft for signs of damage, ensuring proper installation, and replacing the shaft if necessary. Regular maintenance and inspections can help identify and address these issues before they lead to more significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 202969 Water Pump Shaft, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, ensuring the shaft is properly lubricated, and replacing the shaft according to manufacturer guidelines or when signs of failure are detected. Additionally, maintaining the overall health of the engine cooling system can contribute to the shaft’s performance and durability.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a reputation for manufacturing high-quality automotive components. The company’s commitment to excellence is reflected in its products, including the Cummins 202969 Water Pump Shaft, which is designed to meet the demanding requirements of commercial truck engines.

Role of Part 202969 Water Pump Shaft in Engine Systems

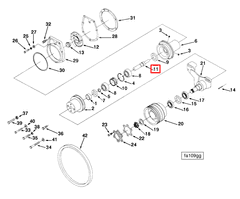

The 202969 water pump shaft is integral to the operation of both the water pump and the fan arrangement within an engine system.

In the water pump, the shaft serves as the central pivot point around which the impeller rotates. This rotation generates the centrifugal force necessary to move coolant through the engine’s passages, ensuring efficient heat dissipation and maintaining optimal operating temperatures. The shaft’s precise alignment and smooth operation are essential for the impeller’s effectiveness, directly influencing the coolant flow rate and pressure.

Within the fan arrangement, the water pump shaft often connects to the fan via a pulley or direct drive mechanism. This connection allows the fan to rotate in sync with the water pump, enhancing the engine’s cooling efficiency. As the engine operates, the rotating fan draws air through the radiator, dissipating heat from the coolant before it recirculates back into the engine. The shaft’s role in this setup ensures that the fan operates at the correct speed relative to engine RPM, contributing to consistent and reliable cooling performance.

Conclusion

The Cummins 202969 Water Pump Shaft is a critical component in the engine cooling system of commercial trucks. Its design and construction ensure efficient coolant circulation, maintaining optimal engine temperatures and enhancing engine performance and durability. Regular maintenance and proper installation are key to maximizing the lifespan and effectiveness of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.