This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

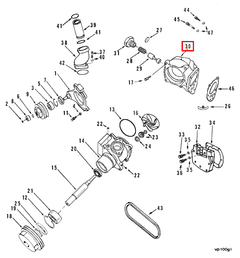

The Cummins 212716 Water Pump Body is a component designed for use in the cooling systems of heavy-duty trucks. Its primary role is to house and support the water pump mechanism, which is responsible for circulating coolant throughout the engine. This circulation is vital for maintaining optimal engine temperature, ensuring efficient operation and longevity of the engine components 1.

Function and Operation

The water pump body operates as a housing for the water pump within the engine cooling system. It facilitates the circulation of coolant by enclosing the impeller, which is driven by a belt connected to the engine. As the impeller rotates, it creates a flow of coolant that is drawn from the engine block, passed through the radiator where it is cooled, and then returned to the engine. This continuous circulation helps in dissipating heat generated by the engine, thereby maintaining a stable operating temperature 2.

Key Features

This Cummins part is constructed with durability and performance in mind. It is typically made from high-quality materials that can withstand the rigors of heavy-duty truck operations. The design includes robust sealing mechanisms to prevent coolant leaks, ensuring efficient coolant circulation. Additionally, the water pump body may feature unique design elements such as reinforced housing to enhance durability and resistance to wear and tear 3.

Benefits

The use of the Cummins 212716 Water Pump Body offers several advantages. It contributes to improved engine efficiency by ensuring consistent coolant flow, which helps in maintaining optimal engine temperature. This, in turn, can lead to enhanced engine performance and longevity. The robust construction and design of the water pump body also provide reliability in demanding conditions, making it suitable for the rigorous operations typical of heavy-duty trucks.

Installation Considerations

Proper installation of the 212716 is crucial for its effective operation. It is recommended to use the appropriate tools and follow manufacturer guidelines to ensure a secure fit and proper alignment. Common pitfalls during installation include improper sealing, which can lead to coolant leaks, and misalignment, which can affect the efficiency of coolant circulation. Careful attention to these details during installation can prevent issues down the line.

Maintenance and Troubleshooting

Routine maintenance of the water pump body is important for its longevity and efficiency. This includes regular inspections for signs of wear or damage, ensuring seals are intact, and checking for any coolant leaks. Common issues that may arise include leaks due to worn seals or gaskets, and impeller wear leading to reduced coolant flow. Troubleshooting steps may involve replacing worn seals or gaskets, and in some cases, the impeller itself, to restore proper function.

Manufacturer Overview

Cummins Inc. is a well-established manufacturer with a strong reputation in the industry for producing high-quality automotive components. The company has a history of innovation and commitment to quality, which is reflected in its wide range of products designed for durability and performance in demanding applications. The Cummins 212716 Water Pump Body is a testament to this commitment, offering reliable performance in the cooling systems of heavy-duty trucks.

Integration with the Water Pump Assembly

In the water pump assembly, the Water Pump Body serves as the housing for the impeller and other internal components. It creates a sealed environment that allows coolant to flow through the engine block and cylinder head, absorbing heat generated during combustion. The design of the Water Pump Body ensures minimal leakage and maximum efficiency in coolant circulation.

Interaction with the WP & Idler System

When integrated with the WP & Idler system, the Water Pump Body works in conjunction with the idler pulley to maintain the correct tension on the drive belt. This ensures that the water pump operates smoothly and efficiently, without slippage or excessive wear on the belt. The Water Pump Body’s robust construction supports these dynamic interactions, contributing to the longevity and reliability of the cooling system.

Role in the Housing Water Pump Configuration

In a housing water pump setup, the Water Pump Body acts as the primary enclosure for the pump mechanism. It protects internal components from external contaminants and ensures that the coolant path remains unobstructed. The precise engineering of the Water Pump Body allows for seamless integration with the engine’s cooling passages, enhancing overall system performance.

Contribution to the Lubricating Oil Cooler

The Water Pump Body also plays a part in systems where a lubricating oil cooler is present. By ensuring consistent coolant flow, it helps maintain the oil at an optimal temperature, which is essential for reducing friction and wear on moving parts. This indirect role highlights the Water Pump Body’s importance in maintaining the overall health of the engine.

Function in the Water and Idler Pump Assembly

In assemblies that combine water and idler pump functions, the Water Pump Body is designed to handle the additional stress and complexity. It ensures that both the coolant and the idler mechanisms operate within specified parameters, contributing to the stability and efficiency of the entire cooling system.

Conclusion

The Cummins 212716 Water Pump Body is a foundational element in the water pump system. Its design and construction are tailored to withstand the pressures and temperatures of engine operation, ensuring that coolant is delivered efficiently to all critical areas. This consistent performance is essential for the engine’s durability and operational effectiveness.

-

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Halderman, J. D. (2012). Automotive Principles: Diagnosis and Service. Prentice Hall.

↩ -

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.