This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3005764 Water Pump Pulley is a component designed for use in commercial trucks. It serves a significant role in the operation of these vehicles by facilitating the efficient functioning of the engine cooling system. This pulley is integral to maintaining optimal engine temperature, which is vital for the longevity and performance of the truck’s engine 2.

Basic Concepts of Water Pump Pulleys

A water pump pulley is a mechanical component that connects the engine’s crankshaft to the water pump via a serpentine belt. Its function is to transfer rotational force from the engine to the water pump, enabling the pump to circulate coolant through the engine. This circulation is crucial for dissipating heat generated during engine operation. The pulley’s design allows it to interact seamlessly with the serpentine belt, ensuring smooth and consistent operation of the water pump 3.

Purpose of the Cummins 3005764 Water Pump Pulley

This Cummins part plays a role in the operation of a truck by driving the water pump. This action facilitates the circulation of coolant through the engine, which helps in maintaining the engine’s temperature within a specified range. Proper coolant circulation is important for preventing overheating, which can lead to engine damage. The pulley’s efficient operation ensures that the water pump functions correctly, contributing to the overall reliability and performance of the truck 2.

Key Features

The 3005764 is characterized by its robust design and the materials used in its construction. It is engineered to withstand the high stresses and temperatures associated with commercial truck engines. The pulley features a precision-machined surface for optimal belt grip and reduced slippage. Additionally, it is constructed from durable materials that offer resistance to wear and corrosion, enhancing its performance and longevity in demanding operating conditions 1.

Benefits

Using this part offers several advantages. It contributes to improved engine cooling efficiency by ensuring consistent and reliable operation of the water pump. This results in more effective heat dissipation from the engine, which can help in maintaining engine performance and longevity. Furthermore, the pulley’s design reduces wear on the water pump, leading to fewer maintenance requirements and lower operational costs over time 2.

Installation and Compatibility

Proper installation of this Cummins part is important for ensuring its effective operation and compatibility with the truck’s engine system. Installation procedures should follow manufacturer guidelines to ensure correct alignment and tension of the serpentine belt. Compatibility with various truck models and engine types should be verified to ensure optimal performance and integration within the engine cooling system 1.

Troubleshooting and Maintenance

Common issues with the 3005764 may include belt slippage or pulley misalignment. Regular inspection and maintenance are recommended to identify and address these issues promptly. Maintenance practices should include checking the pulley and belt for signs of wear or damage, ensuring proper alignment, and maintaining correct belt tension. These practices help in ensuring the pulley’s optimal performance and longevity 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the industry, Cummins is committed to manufacturing high-quality automotive components. The company’s products are known for their reliability, performance, and durability, making them a preferred choice for commercial vehicle applications 2.

Compatibility with Cummins Engines

The 3005764 Water Pump Pulley is designed to fit seamlessly with a variety of Cummins engines, ensuring efficient operation and reliable performance. This part is engineered to meet the stringent requirements of Cummins’ engine systems, providing durability and precision in its function.

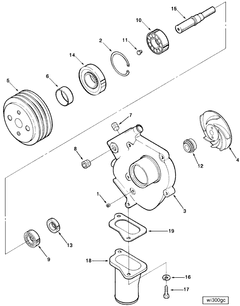

V903 Engine Group

The V903 engine series, known for its robust design and high performance, is one of the key beneficiaries of the 3005764 Water Pump Pulley. This engine group is typically used in heavy-duty applications, where reliability and efficiency are paramount. The 3005764 part is specifically tailored to integrate with the V903 engines, ensuring that the water pump operates smoothly and effectively.

The compatibility of the 3005764 Water Pump Pulley with the V903 engines is a result of meticulous engineering and rigorous testing. This ensures that the pulley fits perfectly, reducing the risk of wear and tear and enhancing the overall lifespan of the engine components.

By choosing the 3005764 Water Pump Pulley for the V903 engines, users can expect a seamless fit and reliable performance, contributing to the longevity and efficiency of their engine systems 2.

Role of 3005764 Water Pump Pulley in Engine Systems

This part is integral to the efficient operation of engine cooling systems. It facilitates the rotation of the water pump, which is essential for circulating coolant throughout the engine.

When the pulley is engaged, it drives the water pump impeller, which in turn moves coolant from the water inlet through the engine block and cylinder head. This circulation helps in dissipating heat generated by combustion, maintaining optimal engine temperature.

The pulley’s connection to the base parts ensures a secure fit and smooth operation. It interfaces with the water inlet connection, allowing for a seamless flow of coolant into the system. This consistent flow is vital for preventing overheating and ensuring the longevity of engine components 3.

Conclusion

In summary, the 3005764 Water Pump Pulley plays a significant role in maintaining the thermal efficiency of engine systems by ensuring reliable coolant circulation. Its robust design, compatibility with Cummins engines, and efficient operation contribute to the overall performance and longevity of commercial truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.