This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Water Pump Impeller (Part #3020479) by Cummins is a component designed to facilitate the efficient operation of the engine cooling system in commercial trucks. Its purpose is to circulate coolant through the engine, ensuring that the engine maintains an optimal operating temperature. This part is significant in the context of truck operation as it contributes to the longevity and reliability of the engine by preventing overheating 1.

Basic Concepts of Water Pump Impellers

A water pump impeller is a rotating component within the water pump of an engine cooling system. It functions by drawing coolant from the engine block and pushing it through the radiator, where it is cooled before returning to the engine. The principles of fluid dynamics, such as centrifugal force and fluid flow, govern the operation of the impeller. As the impeller rotates, it creates a centrifugal force that moves the coolant outward, which then flows through the cooling system 2.

Role of the Water Pump Impeller in Truck Operation

The Water Pump Impeller plays a role in maintaining optimal engine temperature by ensuring a consistent flow of coolant through the engine. This consistent flow is vital for dissipating heat generated during engine operation. By preventing overheating, the impeller contributes to the efficient operation of the engine and helps to maintain the overall performance and reliability of the truck 3.

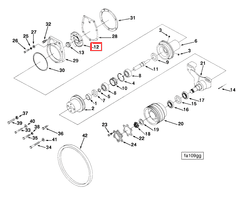

Key Features of the Cummins Water Pump Impeller (Part #3020479)

The Cummins Water Pump Impeller is characterized by its robust design and construction. It is made from durable materials that can withstand the high temperatures and pressures within the engine cooling system. The blade configuration of the impeller is optimized for efficient coolant flow, and it features a design that minimizes wear and tear, enhancing its performance and durability 4.

Benefits of Using the Cummins Water Pump Impeller

The Cummins Water Pump Impeller offers several advantages. Its design contributes to improved cooling efficiency, which is beneficial for maintaining engine temperature within optimal ranges. The reliability and longevity of the impeller are also notable, as it is engineered to withstand the demanding conditions of commercial truck operation. Compared to alternative impeller designs, the Cummins impeller provides a balance of performance, durability, and efficiency 5.

Troubleshooting and Maintenance Tips

To ensure the optimal performance and longevity of the Cummins Water Pump Impeller, it is important to be aware of common issues and perform regular maintenance. Signs of impeller wear or failure may include engine overheating, unusual noises from the water pump, or coolant leaks. Diagnostic procedures may involve inspecting the impeller for damage, checking the coolant flow, and assessing the condition of the water pump bearings. Maintenance practices include regular coolant changes, ensuring the water pump is properly lubricated, and replacing the impeller if signs of wear are detected 6.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for manufacturing high-quality components for commercial vehicles. The company’s commitment to innovation, quality, and customer satisfaction is reflected in its wide range of products, including the Water Pump Impeller (Part #3020479), which is designed to meet the rigorous demands of commercial truck operation 7.

Integration of Part 3020479 Water Pump Impeller in Engine Systems

This part is an essential component within the water pump assembly, playing a significant role in the efficient operation of the engine’s cooling system. When integrated into an engine overhaul kit, the impeller ensures that the water pump functions optimally, facilitating the circulation of coolant throughout the engine block and cylinder head. This circulation is vital for maintaining engine temperature within safe operating limits, thereby preventing overheating and potential engine damage.

During engine rotation, the impeller is driven by a belt or chain connected to the crankshaft. As the engine rotates, the impeller spins, creating a centrifugal force that propels coolant from the water pump body through the engine’s cooling passages. This process is integral to the effective operation of the radiator and heat exchanger, as it ensures that the coolant absorbs excess heat from the engine components and transfers it to the radiator cooling system for dissipation.

In the context of an engine spares set or a set of spares, the impeller is a key replacement part. Its condition directly impacts the reliability of the water pump. A worn or damaged impeller can lead to inefficient coolant flow, resulting in inadequate cooling and increased engine temperatures. Therefore, when performing maintenance or repairs, it is important to inspect the impeller as part of the water pump repair kit to ensure it is in good condition or replace it if necessary.

The impeller also interacts with the PDC BM Assembly, contributing to the overall efficiency of the engine’s cooling system. Proper functioning of the impeller ensures that the PDC BM Assembly receives adequately cooled coolant, which is essential for its optimal performance and longevity.

Conclusion

In summary, the 3020479 Water Pump Impeller is a fundamental component that works in concert with various engine systems to maintain efficient coolant circulation. Its integration within the water pump and interaction with the radiator, heat exchanger, and other cooling components underscores its importance in preserving engine health and performance.

-

{ title : The Automotive Transmission Book Powertrain , author : Robert Fischer, Ferit Kucukay, Gunter Jurgens, Rolf Najork, and Burkhard Pollak , publisher : Springer , date : 2015 }

↩ -

{ title : Automotive Maintenance: Light Repair , author : Rob Thompson , publisher : Cengage Learning , date : 2019 }

↩ -

{ title : Vehicle Dynamics and Control , author : Rajesh Rajamani , publisher : Springer , date : 2005 }

↩ -

{ title : Vehicle Crash Dynamics , author : Matthew Huang , publisher : CRC Press , date : 2002 }

↩ -

{ engine : B6.7 CM2670 B168B , bulletinNumber : Bulletin Number 5659621 , title : Operation and Maintenance Manual }

↩ -

{ title : Automotive Maintenance: Light Repair , author : Rob Thompson , publisher : Cengage Learning , date : 2019 }

↩ -

{ engine : B6.7 CM2670 B168B , bulletinNumber : Bulletin Number 5659621 , title : Operation and Maintenance Manual }

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.