This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3040924 Water Pump Impeller is a critical component in the cooling systems of heavy-duty trucks. It ensures the circulation of coolant within the engine, maintaining optimal operating temperatures and contributing to the engine’s efficiency and longevity 1.

Basic Concepts of Water Pump Impellers

A water pump impeller is a rotating component within a water pump that moves fluid through the system. It operates on the principles of fluid dynamics, where the rotation of the impeller blades creates centrifugal force. This force propels the coolant outward, generating flow through the engine’s cooling passages. The efficiency of this process is essential for dissipating heat generated by the engine, thereby preventing overheating 2.

Role of the 3040924 Water Pump Impeller in Truck Operation

This Cummins part specifically contributes to the cooling system of a truck by ensuring a consistent flow of coolant through the engine. This consistent flow aids in maintaining optimal engine temperature, which is vital for the engine’s performance and durability. By effectively circulating coolant, the impeller helps in dissipating heat away from critical engine components, thus supporting the overall operational efficiency of the truck 3.

Key Features of the 3040924 Water Pump Impeller

The design and construction of this part incorporate several features that enhance its performance and durability. These include the use of high-quality materials resistant to corrosion and wear, a blade design optimized for efficient coolant flow, and construction techniques that ensure robustness under the demanding conditions typical of heavy-duty truck operations.

Benefits of Using the 3040924 Water Pump Impeller

Utilizing this part offers several advantages. These include improved cooling efficiency due to its design, which ensures effective coolant circulation. Additionally, the impeller’s construction contributes to its longevity and reliability, making it suitable for the rigorous environments encountered in heavy-duty truck operations.

Troubleshooting Common Issues with Water Pump Impellers

Common issues associated with water pump impellers, such as leaks, noise, and reduced cooling efficiency, can often be traced back to wear and tear or improper installation. For the 3040924 model, addressing these issues may involve inspecting the impeller for signs of damage, ensuring proper alignment and installation, and maintaining the cooling system to prevent contaminants that could affect impeller performance.

Maintenance Tips for the 3040924 Water Pump Impeller

To ensure the longevity and optimal performance of this part, regular maintenance practices are recommended. These include periodic inspections for wear or damage, cleaning the impeller and its housing to remove any buildup that could impede flow, and following manufacturer guidelines for replacement intervals. Adhering to these practices helps in maintaining the efficiency of the cooling system and the overall performance of the truck.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive and heavy-duty truck industry. The company’s commitment to excellence is reflected in its diverse product range, which includes components like the 3040924 Water Pump Impeller, designed to meet the demanding requirements of modern engines 4.

Role of Part 3040924 Water Pump Impeller in Engine Systems

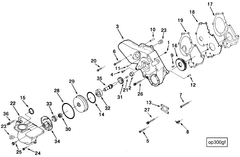

This part is a fundamental component in the efficient operation of engine cooling systems. It is specifically designed to work in harmony with several key components to ensure optimal engine performance and longevity.

Integration with the Water Pump

The Water Pump Impeller is housed within the Water Pump assembly. Its primary function is to move coolant through the engine’s cooling passages. As the impeller rotates, it creates a centrifugal force that propels the coolant from the center of the pump outward, through the engine block and cylinder head. This continuous circulation helps maintain an even temperature throughout the engine, preventing overheating.

Relationship with the Gear Housing

The Gear Housing encases the drive mechanism that rotates the Water Pump Impeller. This housing is typically connected to the engine’s timing belt or chain, ensuring that the impeller spins in sync with the engine’s operation. The precise alignment and secure fit of the impeller within the gear housing are essential for efficient coolant flow and minimal wear on the pump components.

Interaction with the Water Pump Mounting

The Water Pump Mounting secures the water pump to the engine block. This mounting must be robust and correctly aligned to ensure that the impeller operates within the designed parameters. Proper mounting prevents leaks and ensures that the impeller can effectively draw coolant from the Oil Pan and circulate it through the engine.

Coordination with the Oil Pan

Although the Oil Pan primarily stores engine oil, it also plays a role in the cooling system by providing a reservoir for coolant. The Water Pump Impeller draws coolant from the Oil Pan and circulates it through the engine. This interaction ensures that the coolant is consistently available for the impeller to pump, maintaining a stable cooling cycle.

Conclusion

In summary, the 3040924 Water Pump Impeller works in concert with the Water Pump, Gear Housing, Water Pump Mounting, and Oil Pan to facilitate efficient engine cooling. Each component plays a specific role in this system, ensuring that the impeller can effectively circulate coolant and maintain engine temperature within safe limits.

-

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Department of Energy. (2015). Department of Energy Fundamentals Handbook. Department of Energy.

↩ -

Ling, F. F. (2011). The Automotive Body. Springer Science.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSK60 CM2350 K135, Bulletin Number 5504624. Cummins Inc.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.