This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3040925 Water Pump Impeller is a critical component for the efficient operation of the cooling system in heavy-duty trucks. It ensures coolant circulation through the engine, maintaining optimal temperature for performance and longevity. This part’s significance is in its role in maintaining engine efficiency and preventing overheating, which can cause severe engine damage 1.

Basic Concepts of Water Pump Impellers

A water pump impeller is a rotating component within the water pump that moves coolant through the engine cooling system. It operates based on fluid dynamics principles, where the rotation of the impeller blades creates centrifugal force. This force propels the coolant outward, through the pump housing, and into the engine’s cooling passages. The consistent circulation of coolant is vital for dissipating heat generated by the engine’s operation 2.

Role of the 3040925 Water Pump Impeller in Truck Operation

This part plays a role in maintaining optimal engine temperature by ensuring a steady flow of coolant. This consistent flow is crucial for efficient engine operation, as it helps to dissipate heat away from critical engine components. By preventing overheating, the impeller contributes to the overall reliability and performance of the truck 3.

Key Features of the Cummins 3040925 Water Pump Impeller

The design and construction of this Cummins part include features that enhance its performance. It is typically made from durable materials that can withstand the high temperatures and pressures within the cooling system. The blade configuration is engineered to maximize coolant flow efficiency, and the impeller may possess unique attributes such as a balanced design to reduce vibration and wear.

Benefits of Using the Cummins 3040925 Water Pump Impeller

Utilizing this part offers several advantages. It provides improved cooling efficiency, which is beneficial for engines operating under heavy loads or in high-temperature environments. The impeller’s durable construction ensures longevity, and its reliable performance under demanding conditions makes it a valuable component for heavy-duty truck applications.

Installation and Compatibility

Proper installation of 3040925 is important to ensure it functions correctly within the cooling system. Specific procedures and considerations may apply depending on the truck model. It is important to follow manufacturer guidelines to ensure compatibility and correct fitment, which can vary across different vehicle platforms.

Maintenance and Troubleshooting

Maintaining this part involves regular inspection for signs of wear or damage. Common maintenance practices include checking for leaks, ensuring proper alignment, and verifying that the impeller spins freely without obstruction. Troubleshooting may involve addressing issues such as reduced coolant flow, which could indicate a worn impeller or a blockage within the cooling system.

Performance Enhancements

This part contributes to overall engine performance by ensuring efficient heat management. This can lead to improved fuel efficiency, as the engine operates within its designed temperature range. Additionally, the longevity of the cooling system components may be extended due to the impeller’s role in maintaining consistent coolant circulation.

Cummins Corporation

Cummins Inc. is a well-established manufacturer with a reputation for producing high-quality automotive components. The company has a history of innovation and commitment to excellence in the industry. Cummins’ dedication to manufacturing reliable parts is evident in the design and performance of the 3040925 Water Pump Impeller, reflecting the brand’s standards for quality and durability.

Role of Part 3040925 Water Pump Impeller in Engine Systems

The water pump impeller, identified by part number 3040925, is integral to the operation of the water pump kit within engine systems. This component is responsible for the circulation of coolant throughout the engine, ensuring that all critical components remain within optimal temperature ranges during operation.

When the engine is running, the water pump impeller is driven by a belt connected to the crankshaft. As the impeller rotates, it creates centrifugal force, which propels coolant from the water pump through the engine’s cooling passages. This process facilitates the transfer of heat away from the engine block and cylinder heads, which are areas prone to overheating due to the combustion process.

The efficiency of the water pump impeller directly influences the effectiveness of the cooling system. A well-functioning impeller ensures a consistent flow of coolant, which is essential for maintaining engine temperature stability. Inadequate performance of the impeller can lead to insufficient coolant circulation, resulting in hotspots within the engine and potential overheating.

In conjunction with the thermostat, the water pump impeller helps regulate the temperature of the engine. The thermostat controls the flow of coolant to the radiator, allowing it to cool before returning to the engine. The impeller’s role is to maintain a steady flow, ensuring that the thermostat can effectively manage the cooling process.

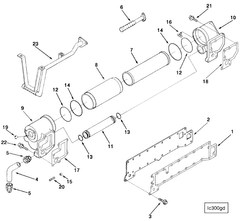

The water pump kit, which includes the impeller, housing, gaskets, and seals, is designed to work in harmony. The impeller’s precise fit within the housing is vital for minimizing leaks and maximizing efficiency. The gaskets and seals prevent coolant loss, ensuring that the system remains pressurized and operates effectively.

Conclusion

In summary, the water pump impeller (part 3040925) is a key component in the water pump kit, playing a significant role in the engine’s cooling system. Its proper function is essential for the overall performance and longevity of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.