This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3066152 Water Pump is a critical component for commercial trucks, designed to circulate coolant within the engine cooling system. This circulation is essential for maintaining optimal engine temperature, which is vital for the efficient operation and longevity of commercial trucks 1.

Basic Concepts of Water Pumps

Water pumps operate on fundamental principles that involve the circulation of coolant through the engine cooling system. This process is crucial for dissipating heat generated during engine operation. By maintaining an optimal engine temperature, water pumps contribute to the overall performance and longevity of the engine 2.

Purpose of the Cummins 3066152 Water Pump

The Cummins 3066152 Water Pump facilitates the circulation of coolant through the engine, helping to regulate engine temperature. This regulation ensures that the engine operates within a safe temperature range, which is important for engine efficiency, performance, and longevity 3.

Key Features

The Cummins 3066152 Water Pump is characterized by several key features that enhance its performance and durability. These include a robust design, the use of high-quality materials, and unique characteristics such as precision engineering and efficient coolant flow. These features contribute to the pump’s reliability and effectiveness in demanding commercial truck applications.

Benefits

Using the Cummins 3066152 Water Pump offers several benefits. These include improved engine cooling efficiency, which helps maintain optimal engine temperature under various operating conditions. The pump’s enhanced reliability reduces the likelihood of coolant system failures, contributing to overall engine durability. Additionally, the efficient operation of the pump can lead to potential cost savings over time by minimizing the need for frequent repairs or replacements.

Installation Considerations

Proper installation of the Cummins 3066152 Water Pump is important for ensuring its effective operation. Guidelines and recommendations for installation include verifying that all prerequisites are met, using the appropriate tools, and following a series of steps to ensure a successful installation process. Attention to detail during installation helps prevent issues that could affect the pump’s performance.

Maintenance Tips

Maintaining the Cummins 3066152 Water Pump is important for ensuring optimal performance and longevity. Practical advice includes regular inspection procedures to check for signs of wear or damage, adhering to recommended maintenance intervals for replacement or servicing, and being vigilant for any indications of potential issues. Early identification of problems can prevent more significant issues down the line.

Troubleshooting Common Issues

Common problems that may arise with the Cummins 3066152 Water Pump include leaks, reduced coolant flow, and pump failure. Identifying these issues early and applying suggested solutions can help mitigate their impact. Preventive measures, such as regular maintenance and inspections, can also help reduce the likelihood of these problems occurring.

Cummins Overview

Cummins Inc. is a well-established manufacturer with a reputation for producing high-quality automotive components. The company’s history and commitment to excellence are reflected in its products, including the Cummins 3066152 Water Pump. Cummins’ dedication to manufacturing reliable and durable components underscores its position in the industry.

Role of Part 3066152 Water Pump in Engine Systems

The Cummins 3066152 Water Pump is an essential component in the cooling system of an engine, ensuring optimal performance and longevity of the engine components. It operates by circulating coolant through the engine block and cylinder head, effectively managing the engine’s temperature.

Integration with Engine Components

-

Connection: The water pump is connected to the engine via a series of hoses and pipes. These connections are vital for the continuous flow of coolant, which is necessary for maintaining the engine’s operational temperature.

-

Water Inlet: The water inlet is where the coolant enters the water pump. This component is directly linked to the pump, ensuring a steady supply of coolant is available for circulation.

-

Kit Turbocharger Repair: In turbocharged engines, the water pump plays a role in cooling the turbocharger. It helps in maintaining the efficiency and reliability of the turbocharger by ensuring that it does not overheat.

-

Pump: The water pump itself is responsible for the circulation of coolant. It is driven by a belt connected to the engine, which allows it to operate in sync with the engine’s revolutions.

-

Water: The coolant, often a mixture of water and antifreeze, is circulated by the water pump. This liquid is essential for heat dissipation and protection against freezing in cold conditions.

-

Water Pump: As a component, the water pump ensures that the coolant is consistently circulated through the engine. This circulation is necessary for dissipating heat generated by the combustion process.

The effective operation of the water pump is dependent on its seamless integration with these components, ensuring that the engine remains at an optimal temperature under various operating conditions.

Conclusion

The Cummins 3066152 Water Pump is a vital component for maintaining the optimal performance and longevity of commercial truck engines. Its role in circulating coolant and regulating engine temperature is crucial for the efficient operation of these vehicles. Proper installation, maintenance, and troubleshooting are essential for ensuring the reliability and effectiveness of this part in demanding applications.

-

The Motor Vehicle, TK Garrett, K Newton, W Steeds, Reed Educational and Professional Publishing Ltd, 2001.

↩ -

Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems, Konrad Reif, Springer Vieweg, 2014.

↩ -

The Automotive Transmission Book Powertrain, Robert Fischer, Ferit Kucukay, Gunter Jurgens, Rolf Najork, and Burkhard Pollak, Springer, 2015.

↩

SPECIFICATIONS

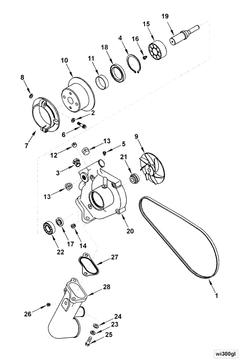

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| Reducing Pipe Bushing | 1 | S983 |

| Retaining Ring | 1 | 70183 |

| Twelve Point Cap Screw | 2 | 191772 |

| Water Pump Sheave Pulley | 1 | 197582 |

| Mounting Spacer | 2 | 203408 |

| Water Pump Impeller | 1 | 3002483 |

| Pulley | 1 | 3007307 |

| Pipe Plug | 3 | 3008469 |

| Pipe Plug | 1 | 3013786 |

| Ball Bearing | 1 | 3017035 |

| Pipe Plug | 3 | 3025458 |

| Oil Seal | 1 | 3038999 |

| Oil Seal | 1 | 3039000 |

| Water Pump Shaft | 1 | 3054160 |

| Water Pump Seal | 1 | 3071085 |

| Ball Bearing | 1 | 3077646 |

| Pipe Plug | 1 | 4931643 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.