This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

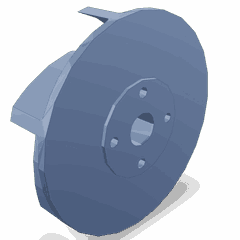

The Cummins 3172019 Water Pump Impeller is a component designed to facilitate the efficient operation of the cooling system in heavy-duty trucks. Its purpose is to circulate coolant through the engine, ensuring that the temperature remains within optimal ranges for performance and longevity. The significance of this part lies in its ability to maintain engine efficiency and prevent overheating, which can lead to severe engine damage 1.

Basic Concepts of Water Pump Impellers

A water pump impeller is a rotating component within the water pump that moves coolant through the engine cooling system. It operates on the principles of centrifugal force, where the impeller’s rotation creates a pressure differential that propels the coolant outward and into the engine’s cooling passages. This process is fundamental to dissipating heat generated by the engine, ensuring that the operating temperature remains stable 2.

Role of the 3172019 Water Pump Impeller in Truck Operation

The 3172019 Water Pump Impeller plays a role in maintaining optimal engine temperature by ensuring a consistent flow of coolant. This consistent flow is vital for efficient engine operation, as it helps to dissipate heat away from critical engine components. By preventing overheating, the impeller contributes to the overall reliability and performance of the truck 3.

Key Features of the 3172019 Water Pump Impeller

The design of the 3172019 Water Pump Impeller incorporates several features that enhance its effectiveness and reliability. These include precision-engineered blades that optimize coolant flow, durable materials resistant to corrosion and wear, and engineering specifications tailored to meet the demanding conditions of heavy-duty truck applications 4.

Benefits of Using the 3172019 Water Pump Impeller

Utilizing the 3172019 Water Pump Impeller offers several advantages. These include improved cooling efficiency due to its design, enhanced durability that ensures long-term performance, and compatibility with Cummins engines, which guarantees seamless integration and operation within the cooling system.

Installation and Compatibility

Proper installation of the 3172019 Water Pump Impeller is crucial for its effective operation. Guidelines for installation include ensuring a proper seal to prevent leaks, aligning the impeller correctly within the pump housing, and following any specific requirements for different truck models to ensure compatibility and optimal performance.

Maintenance and Troubleshooting

Regular maintenance practices are recommended to ensure the longevity and performance of the 3172019 Water Pump Impeller. These practices include periodic inspections for wear or damage, cleaning to remove any debris that may affect performance, and addressing any leaks promptly. Common issues may include impeller wear or gasket failure, and diagnostic tips involve checking for consistent coolant flow and engine temperature stability.

Performance and Efficiency

The use of the 3172019 Water Pump Impeller in heavy-duty truck applications is associated with notable performance metrics and efficiency gains. Its design contributes to more effective heat dissipation, which can lead to improved engine performance and fuel efficiency. Additionally, the impeller’s durability reduces the frequency of replacements, contributing to lower maintenance costs over time.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industry. The company’s product range includes engines and components designed to meet the demanding requirements of various applications, ensuring optimal performance and efficiency.

Water Pump Impeller (Part 3172019) Compatibility with Cummins Engines

The Water Pump Impeller, identified by part number 3172019, is a critical component in the cooling systems of various Cummins engines. This part is designed to circulate coolant throughout the engine, ensuring optimal temperature regulation and preventing overheating. Below is a detailed description of how this impeller fits with the specified Cummins engines.

QSK45 CM500 and QSK60 CM500

The QSK45 CM500 and QSK60 CM500 engines both feature a similar cooling system architecture, making the Water Pump Impeller part 3172019 a suitable fit for both. These engines are designed for heavy-duty applications, and the impeller’s role in maintaining efficient coolant flow is crucial for their performance and longevity.

QSK60 CM850 MCRS and QSK60 G CM2358 K110

The QSK60 CM850 MCRS and QSK60 G CM2358 K110 engines, while differing in some specifications, share a common requirement for effective coolant circulation. The Water Pump Impeller part 3172019 is engineered to meet these needs, ensuring that the coolant is adequately pumped through the engine’s cooling system. This is particularly important for maintaining the high performance and reliability expected from these engines.

QSK60G

The QSK60G engine also benefits from the Water Pump Impeller part 3172019. This engine is designed for demanding applications, and the impeller’s role in maintaining consistent coolant flow is vital for its operation. The design of the impeller ensures that it can handle the specific demands of the QSK60G engine.

QSK78 CM500

The QSK78 CM500 engine, with its robust design for heavy-duty applications, requires a reliable water pump impeller to maintain its cooling system’s efficiency. The Water Pump Impeller part 3172019 is specifically engineered to fit this engine, ensuring that coolant is effectively circulated to prevent overheating and maintain optimal engine performance.

Role of Part 3172019 Water Pump Impeller in Engine Systems

The 3172019 Water Pump Impeller is an integral component within the water pump assembly, facilitating the circulation of coolant throughout the engine system. Its function is to draw coolant from the engine block and propel it through the radiator, where it is cooled before being recirculated. This continuous flow is essential for maintaining optimal engine temperature, preventing overheating, and ensuring efficient engine performance.

In the context of a Water Pump Kit or a W.P. Repair Major Kit, the impeller works in conjunction with other components such as the water pump housing, gaskets, and seals. The impeller’s precise arrangement within the pump housing ensures a tight fit, minimizing leaks and maximizing coolant flow efficiency.

When integrated into a W.P. Repair Major scenario, the impeller’s role becomes even more pronounced. During major repairs, the impeller must be carefully inspected for wear or damage. Any imperfections can lead to reduced pumping efficiency, increased engine temperatures, and potential engine damage. Therefore, replacing or repairing the impeller as part of a major kit is a standard practice to restore the water pump’s functionality.

The impeller’s interaction with the pump’s drive mechanism, typically a belt or chain, is also significant. This drive arrangement ensures that the impeller spins at the correct speed to maintain adequate coolant circulation. Any misalignment or wear in this arrangement can affect the impeller’s performance, underscoring the importance of thorough inspection and maintenance.

Conclusion

The Cummins 3172019 Water Pump Impeller is a critical component in the cooling systems of heavy-duty trucks, ensuring optimal engine temperature and preventing overheating. Its design and features contribute to efficient coolant circulation, enhancing engine performance and reliability. Proper installation, maintenance, and compatibility with Cummins engines are essential for its effective operation. The impeller’s role in major repair kits highlights its importance in maintaining engine health and performance.

-

Reif, Konrad. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩ -

Reif, Konrad Ed. Diesel Engine Management Systems and Components. Springer Vieweg, 2014.

↩ -

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩ -

Huang, Matthew. Vehicle Crash Dynamics. CRC Press, 2002.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.