Understanding The Cummins 4900447 Water Pump Gasket

Introduction To Water Pump Gaskets

Water pump gaskets are critical components in the engine cooling system of commercial trucks. They ensure a watertight seal between the water pump and the engine block, preventing coolant leaks that could lead to engine overheating and damage. This article delves into the specifics of the Cummins 4900447 Water Pump Gasket, its purpose, and its role in maintaining the operational integrity of commercial trucks.

Basic Concepts Of Water Pump Gaskets

A water pump gasket is a thin, flexible material placed between the water pump and the engine block. It is designed to create a seal that prevents coolant from leaking out of the pump. The gasket must withstand high temperatures and pressures, maintaining its integrity over time to ensure the cooling system functions correctly 1.

The Role Of The Cummins 4900447 Water Pump Gasket

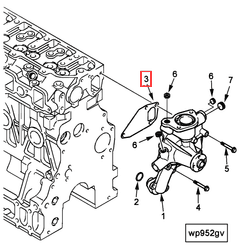

The Cummins 4900447 Water Pump Gasket is specifically engineered for use in Cummins engines, known for their durability and reliability in heavy-duty applications. This gasket plays a crucial role in the engine’s cooling system by ensuring that the water pump remains sealed against the engine block. This seal is vital for maintaining the correct pressure and temperature within the cooling system, preventing engine overheating and potential mechanical failures 2.

Importance In Truck Operations

In commercial trucks, maintaining optimal engine temperature is essential for performance and longevity. The water pump circulates coolant through the engine, absorbing heat and transferring it to the radiator, where it is dissipated. A compromised water pump gasket can lead to coolant leaks, reducing the efficiency of the cooling system and potentially causing severe engine damage. Regular inspection and maintenance of the water pump gasket are therefore critical for the reliable operation of commercial trucks 3.

Troubleshooting And Maintenance

Identifying issues with the water pump gasket early can prevent significant problems. Common signs of a failing water pump gasket include:

- Coolant Leaks: Visible leaks around the water pump area.

- Overheating Engine: Increased engine temperature readings.

- Reduced Coolant Levels: Frequent need to top up the coolant reservoir.

To troubleshoot, inspect the area around the water pump for any signs of coolant. If a leak is suspected, it is essential to address it promptly to avoid engine damage. Maintenance involves regularly checking the gasket for wear and tear and replacing it as needed. Cummins recommends following the manufacturer’s maintenance schedule for optimal performance 4.

Cummins: A Leader In Engine Technology

Cummins is a renowned manufacturer of diesel engines, known for their reliability and efficiency in heavy-duty applications. Their parts, including the 4900447 Water Pump Gasket, are designed to meet the rigorous demands of commercial truck operations. Cummins’ commitment to quality and innovation ensures that their parts perform reliably under the most challenging conditions 5.

Expert Insights

Understanding the importance of the water pump gasket in the engine’s cooling system is crucial for engineers, mechanics, and fleet operators. Proper maintenance and timely replacement of the water pump gasket can prevent costly repairs and downtime, ensuring the continued reliability and efficiency of commercial trucks. Cummins’ expertise in engine technology provides confidence in the performance and durability of their parts, making them a trusted choice for heavy-duty applications.

Conclusion

The Cummins 4900447 Water Pump Gasket is a vital component in the cooling system of commercial trucks, ensuring a secure seal between the water pump and the engine block. Its role in preventing coolant leaks and maintaining optimal engine temperature is critical for the performance and longevity of the vehicle. Regular maintenance and timely replacement of this part are essential practices for fleet operators and mechanics to ensure the reliable operation of commercial trucks.

-

Automotive Braking Systems, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning LLC, 2019

↩ -

Design and Development of Heavy Duty Diesel Engines: A Handbook, P. A. Lakshminarayanan, Avinash Kumar Agarwal

↩ -

Diesel Engine System Design, Qianfan Xin

↩ -

Hillier’s Fundamentals of Motor Vehicle Technology Book 1, Peter Coombs and Victor Hillier, 5th Edition

↩ -

X15 CM2450 X134B - Performance Series, Bulletin Number 5613372, Operation and Maintenance Manual

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.