This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The C0131034200 Water Pump Pulley is a component designed for use in commercial trucks. Its purpose is to facilitate the operation of the water pump, which is integral to the engine cooling system. The significance of this pulley lies in its role in maintaining optimal engine temperature, thereby contributing to the overall efficiency and longevity of the truck’s engine 1.

Basic Concepts of Water Pump Pulleys

A water pump pulley is a mechanical component that connects the water pump to the engine’s drive system via the serpentine belt. Its function within the engine cooling system is to transfer rotational force from the engine to the water pump, enabling the circulation of coolant through the engine. This interaction ensures that the engine remains at an optimal operating temperature, preventing overheating and potential damage 2.

Purpose and Role in Truck Operation

The C0131034200 plays a role in the operation of a truck by driving the water pump to circulate coolant through the engine. This circulation is vital for dissipating heat generated during engine operation, thus maintaining engine temperature within specified limits. Efficient coolant circulation contributes to stable engine performance and longevity 3.

Key Features

This Cummins part is constructed from materials that enhance durability and efficiency. Its design includes elements that ensure smooth operation and reduce wear on the serpentine belt. Unique characteristics may include specific groove patterns for belt engagement or a balanced design to minimize vibrations.

Benefits

Using the C0131034200 offers several benefits. These include improved engine cooling efficiency due to effective coolant circulation, reduced wear on the serpentine belt through precise engagement, and enhanced overall engine performance and longevity as a result of maintained optimal operating temperatures.

Troubleshooting and Maintenance

Common issues with water pump pulleys may include wear, misalignment, or noise. Troubleshooting steps involve inspecting the pulley for signs of damage or wear, ensuring proper alignment with the serpentine belt, and listening for unusual noises that may indicate a problem. Regular maintenance practices, such as checking for belt wear and ensuring proper pulley alignment, can help maintain optimal performance and longevity.

Installation Considerations

When installing the C0131034200, it is important to consider proper alignment with the engine’s drive system, adhere to torque specifications for securing the pulley, and ensure compatibility with other engine components. These considerations help ensure efficient operation and prevent potential issues.

Performance Under Various Conditions

The C0131034200 is designed to perform under different operating conditions, including high temperatures, heavy loads, or rough terrain. Factors that may affect its performance include the quality of the coolant, the condition of the serpentine belt, and the overall maintenance of the engine cooling system.

Comparisons with Other Water Pump Pulleys

Comparative analysis of the C0131034200 with similar products from other manufacturers may highlight differences in design, performance, and durability. These differences can include material construction, design elements for efficiency, and specific features that enhance compatibility or performance in commercial truck applications.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its wide range of engine and component offerings. The company’s reputation is built on a history of innovation, quality, and reliability, making its products, including the C0131034200, a preferred choice for many fleet operators and maintenance professionals.

Compatibility with Cummins Engines

The Water Pump Pulley part number C0131034200, manufactured by Cummins, is designed to fit seamlessly with a range of Cummins engines. This part is crucial for the proper functioning of the engine’s water pump, ensuring that coolant is circulated efficiently throughout the engine to maintain optimal operating temperatures.

3A1.7 and 6A3.4 Engines

The 3A1.7 and 6A3.4 engines, both known for their reliability and performance, utilize the C0131034200. This pulley is engineered to match the specific design and requirements of these engines, ensuring a precise fit and reliable operation.

A2300 Engine

The A2300 engine, another robust and dependable model in the Cummins lineup, also benefits from the use of the C0131034200. This part is specifically tailored to fit the unique specifications of the A2300 engine, ensuring that the water pump operates smoothly and efficiently.

Role in Engine Systems

The C0131034200 is an integral component in the efficient operation of various engine systems, particularly those involving cooling and raw water circulation.

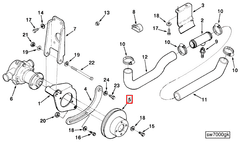

Interaction with the Pump

The pulley is directly connected to the pump, facilitating the transfer of mechanical energy from the engine to the pump mechanism. This ensures that the pump operates at the correct speed to maintain optimal coolant flow through the engine, which is essential for temperature regulation.

Integration with the Raw Water Pump

In marine or industrial engines where raw water is used for cooling, the C0131034200 pulley plays a significant role. It drives the raw water pump, which circulates water through the engine’s cooling passages. This process helps dissipate heat generated by the engine, preventing overheating and ensuring consistent performance.

Connection to the Fan Drive

The pulley is often linked to the fan drive system. As the engine operates, the pulley rotates, driving the fan which aids in cooling the engine by drawing air through the radiator. This is particularly important in environments where the engine may be subjected to high temperatures or heavy loads.

Role in the Front Drive System

In engines where a front drive system is employed, the C0131034200 pulley is a key component. It ensures that the front-mounted accessories, such as the alternator or air conditioning compressor, receive the necessary drive force from the engine. This is achieved through a series of belts or chains that connect the pulley to these accessories.

Interaction with the Front Drive Adapter

The front drive adapter often interfaces with the C0131034200 pulley to facilitate the connection between the engine and the driven accessories. This adapter ensures a secure and efficient transfer of power, minimizing slippage and maximizing the efficiency of the driven components.

Contribution to the Raw Water System

In systems utilizing raw water for cooling, the pulley’s role extends to ensuring the raw water pump operates efficiently. This is vital for maintaining the correct flow of raw water through the engine, which is crucial for effective heat management in demanding operational conditions.

Conclusion

The C0131034200 Water Pump Pulley is a fundamental component in the interplay between the engine and its cooling systems, ensuring that all interconnected parts function harmoniously to maintain engine health and performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.