This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 202119 Water Transfer Tube is a component designed for use in commercial trucks. It facilitates the transfer of coolant within the engine’s cooling system, playing a role in maintaining optimal engine temperature during operation.

Basic Concepts of Water Transfer Tubes

A water transfer tube is a conduit that allows coolant to circulate between different parts of a truck’s cooling system. This circulation helps dissipate heat generated by the engine, ensuring that the engine operates within a safe temperature range. The efficiency of a water transfer tube is vital for the overall performance and longevity of the engine 1.

Purpose of the 202119 Water Transfer Tube

This Cummins part is specifically engineered to enhance the cooling system’s efficiency in commercial trucks. It routes coolant to critical areas of the engine, aiding in the regulation of engine temperature. This component contributes to the engine’s overall performance by ensuring that it remains within optimal operating temperatures, thereby supporting efficient combustion and reducing the risk of overheating 2.

Key Features

The 202119 is constructed from durable materials that resist corrosion and wear, ensuring longevity in demanding environments. Its design includes precise fittings and connections that facilitate easy installation and secure attachment within the cooling system. Additionally, the tube’s smooth interior reduces flow resistance, enhancing coolant circulation efficiency.

Benefits

Utilizing this Cummins part offers several advantages. It improves the cooling system’s efficiency by ensuring consistent coolant flow, which helps maintain engine temperature more effectively. The tube’s durable construction contributes to its longevity, potentially reducing maintenance and replacement costs for fleet operators. Moreover, its efficient design can lead to improved engine performance and reliability.

Installation Considerations

Proper installation of the 202119 is crucial for its effective function. It is recommended to follow manufacturer guidelines, ensuring that all connections are secure and that the tube is correctly positioned within the cooling system. Tools such as wrenches and sealants may be required for installation, and it is advisable to perform the installation with the engine cool to avoid burns or injuries.

Troubleshooting Common Issues

Common issues with the 202119 may include leaks, blockages, or corrosion. To address leaks, inspect all connections for tightness and integrity, and apply sealant if necessary. Blockages can be resolved by flushing the cooling system and ensuring that the tube is clear of debris. Corrosion may require replacement of the affected section or the entire tube, depending on the extent of damage.

Maintenance Tips

To ensure the longevity and optimal performance of the 202119, regular maintenance is recommended. This includes periodic inspection for signs of wear, corrosion, or leaks. Cleaning the tube and the cooling system can prevent blockages and ensure efficient coolant flow. Replacement guidelines should be followed based on the manufacturer’s recommendations or if significant wear or damage is observed.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. Its product offerings include a wide range of engines, components, and technologies designed to meet the diverse needs of its customers.

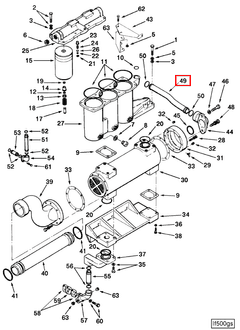

Cummins Water Transfer Tube (Part 202119) in V28 Engines

The Cummins Water Transfer Tube, identified by part number 202119, plays a role in the cooling system of V28 engines. This component is integral to maintaining the optimal operating temperature of the engine by facilitating the transfer of coolant between various parts of the engine’s cooling system.

In V28 engines, the water transfer tube ensures that coolant is evenly distributed, preventing localized overheating and ensuring that all parts of the engine are adequately cooled. This is particularly important in high-performance or heavy-duty engines, where the risk of overheating can lead to significant damage or failure.

The design and placement of the water transfer tube in V28 engines are meticulously engineered to handle the specific demands of these powerful engines. It is constructed from high-quality materials to withstand the extreme pressures and temperatures encountered in these applications.

The water transfer tube is a component that integrates seamlessly with other parts of the engine’s cooling system, ensuring that the engine operates efficiently and reliably under a variety of conditions.

Role of Part 202119 Water Transfer Tube in Engine Systems

The part 202119 Water Transfer Tube is a component in the efficient operation of various engine systems, particularly those involving the cooling and filtration of lubricating oils. Its primary function is to facilitate the transfer of cooling water between different components, ensuring optimal temperature regulation and performance.

Integration with Filter Cooler Systems

In systems equipped with a filter cooler, the Water Transfer Tube plays a role. It connects the filter cooler to other parts of the engine, allowing for the circulation of cooling water. This water helps in maintaining the temperature of the oil as it passes through the filter, ensuring that the oil remains within the desired viscosity range for effective lubrication.

Functionality in Lube Oil Filter and Cooler Assemblies

When integrated with lube oil filter and cooler assemblies, the Water Transfer Tube ensures that the cooling water is efficiently distributed. This is vital for the lube oil filter’s performance, as it prevents overheating, which can lead to a breakdown in the filtration process and contamination of the oil.

Role in Lubricating Oil Cooler Mounting Filter Systems

In lubricating oil cooler mounting filter systems, the Water Transfer Tube is responsible for transferring cooling water to the lubricating oil cooler. This is for dissipating the heat generated by the engine, thereby protecting the oil from thermal degradation and ensuring its longevity and effectiveness in lubricating engine components.

Application in Lubricating Oil Filter Systems

For lubricating oil filter systems, the Water Transfer Tube is integral in maintaining the filter’s efficiency. By ensuring a consistent flow of cooling water, it helps in preventing the oil from overheating, which can otherwise lead to a reduction in the filter’s ability to remove contaminants effectively.

Importance in Oil Filter / Cooler Units

In oil filter / cooler units, the Water Transfer Tube is a component that ensures the cooling water is effectively utilized. This is important for both the filtration and cooling aspects of the unit, as it helps in maintaining the oil at an optimal temperature, thereby enhancing the overall performance and lifespan of the engine.

Conclusion

The Cummins 202119 Water Transfer Tube is a vital component in the cooling systems of commercial trucks and various engine systems. Its efficient design and durable construction contribute to the optimal performance and longevity of engines by ensuring consistent coolant flow and temperature regulation. Regular maintenance and proper installation are key to maximizing the benefits of this part, ultimately leading to improved engine reliability and reduced operational costs.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.