This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

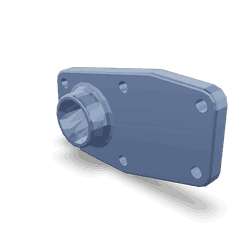

The Cummins 208129 Water Header Cover is a component designed for use in the engine cooling systems of heavy-duty trucks. Its primary role is to facilitate the efficient circulation of coolant within the engine, ensuring optimal operating temperatures are maintained. This part is integral to the overall performance and longevity of the engine by contributing to effective thermal management 1.

Purpose and Function

The Water Header Cover plays a role in the engine cooling system by directing the flow of coolant to various parts of the engine. It helps maintain system pressure, which is vital for the proper functioning of the cooling system. By ensuring that coolant is evenly distributed, it aids in preventing hotspots and maintaining consistent engine temperatures, which is crucial for engine efficiency and durability 2.

Key Features

This Cummins part is characterized by its robust construction and precise engineering. It is made from high-quality materials that are resistant to corrosion and wear, ensuring long-term reliability. The design of the cover is tailored to fit specific Cummins engine models, providing a secure and effective seal. Its construction ensures that it can withstand the high pressures and temperatures typical in heavy-duty engine environments 3.

Benefits

Using the 208129 Water Header Cover can lead to several advantages. It contributes to improved engine performance by ensuring that the engine remains at an optimal temperature. The durable construction of the cover enhances the overall durability of the cooling system, reducing the likelihood of leaks and other issues. Additionally, it provides reliable coolant management, which is essential for the consistent operation of the engine.

Installation Process

Installing this part requires careful attention to detail. Begin by ensuring that the engine is cool and that all necessary tools are at hand. The installation process involves removing the old cover, cleaning the mating surface, and then positioning the new cover. It is important to align the cover correctly and secure it in place according to the manufacturer’s guidelines. This ensures a proper seal and effective coolant flow.

Maintenance Tips

To ensure the longevity and effectiveness of the Water Header Cover, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, such as cracks or leaks. Cleaning the cover and its mating surfaces can prevent the buildup of debris that might affect its performance. Additionally, monitoring the coolant levels and condition can help identify potential issues before they become serious problems.

Troubleshooting Common Issues

Common issues with the Water Header Cover may include leaks, corrosion, and problems with coolant flow. If a leak is detected, it is important to identify the source and address it promptly to prevent coolant loss and potential engine damage. Corrosion can be mitigated through regular cleaning and the use of compatible coolants. Ensuring that the cover is properly aligned and sealed can help resolve coolant flow issues.

Manufacturer Information

Cummins Inc. is a well-established manufacturer in the heavy-duty truck industry, known for its wide range of engine and component products. The company has a reputation for producing high-quality, reliable parts that are designed to meet the demanding requirements of heavy-duty applications. Cummins’ commitment to innovation and customer satisfaction is reflected in its product offerings, including the Cummins 208129 Water Header Cover.

Conclusion

The Cummins 208129 Water Header Cover is a vital component in the engine cooling system of heavy-duty trucks. Its robust construction, precise engineering, and reliable performance contribute to the efficient operation and longevity of the engine. Regular maintenance and prompt troubleshooting of common issues can ensure the continued effectiveness of this part.

-

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality, Elsevier, 2021.

↩ -

Konrad Reif Ed, Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems, Springer Vieweg, 2014.

↩ -

Michael Hilgers, Electrical Systems and Mechatronics, Second Edition, Springer Vieweg, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.