This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

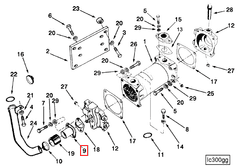

Introduction

The Water Transfer Connection 208629, a component designed by Cummins for commercial trucks, facilitates the efficient transfer of coolant within the truck’s cooling system. This ensures the engine operates within optimal temperature ranges, contributing to the overall performance and longevity of the engine 1.

Basic Concepts of Water Transfer Connection

Water transfer connections in commercial trucks are critical for moving coolant from one part of the engine to another. These connections ensure that heat generated by the engine is effectively dissipated. The coolant circulates through various engine components, absorbing heat and then transferring it to the radiator where it is cooled before recirculating. The efficiency of this process is influenced by the design and functionality of the water transfer connections 2.

Purpose of Water Transfer Connection 208629

The Water Transfer Connection 208629 is designed to enhance the transfer of coolant in the truck’s cooling system. It connects different sections of the cooling pathway, allowing for seamless coolant flow. By ensuring consistent and efficient coolant circulation, this part helps in maintaining the engine’s temperature, which is essential for optimal performance and longevity 3.

Key Features

The Water Transfer Connection 208629 is constructed from durable materials that can withstand the high temperatures and pressures within the engine cooling system. Its design includes precise fittings and seals to ensure a leak-free connection. Additionally, it may incorporate features such as reinforced walls or specialized coatings to further improve durability and efficiency.

Benefits

The advantages of using the Water Transfer Connection 208629 include improved coolant flow, which leads to better heat management within the engine. Its durable construction ensures longevity, reducing the need for frequent replacements. Furthermore, by maintaining optimal engine temperatures, this part can contribute to overall engine efficiency, potentially leading to better fuel economy and reduced emissions.

Installation Process

Installing the Water Transfer Connection 208629 requires careful attention to detail. Begin by ensuring the engine is cool and the cooling system is drained. Locate the appropriate connection points within the cooling system. Apply any necessary sealants to the connection points as per the manufacturer’s recommendations. Carefully align the Water Transfer Connection 208629 with the connection points and secure it in place. Finally, refill the cooling system with the appropriate coolant and check for leaks.

Common Issues and Troubleshooting

Typical problems with the Water Transfer Connection 208629 may include leaks, blockages, or connection failures. If a leak is detected, it may be necessary to re-seal or replace the connection. Blockages can often be resolved by flushing the cooling system. Connection failures may require a thorough inspection to determine the cause, which could range from improper installation to material fatigue.

Maintenance Tips

To ensure the longevity and optimal performance of the Water Transfer Connection 208629, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, ensuring all connections are secure, and checking for leaks. Additionally, adhering to the manufacturer’s recommendations for coolant type and change intervals can help maintain the efficiency of the cooling system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. Their product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial applications.

Role of Part 208629 Water Transfer Connection in Engine Systems

The Water Transfer Connection, identified as part 208629, is integral to the efficient operation of several engine components, ensuring optimal performance and longevity.

Integration with Gear Oil Cooler

In systems equipped with a Gear Oil Cooler, the Water Transfer Connection facilitates the circulation of coolant between the engine and the cooler. This process is essential for maintaining the oil at an optimal temperature, which in turn reduces wear on the gear components and enhances the overall efficiency of the system.

Function in Heat Exchanger Systems

When incorporated into Heat Exchanger setups, the Water Transfer Connection plays a pivotal role in transferring thermal energy from the engine coolant to another fluid. This exchange is vital for regulating engine temperature, preventing overheating, and ensuring that the engine operates within its designed parameters.

Application in Marine Gear Oil Coolers

For Marine Gear Oil Coolers, the Water Transfer Connection is particularly significant. It ensures that the cooling process is consistent and effective, even in the challenging environments typical of marine applications. This consistency is key to protecting the gear oil from degradation and maintaining the reliability of the marine propulsion system.

Conclusion

In each of these applications, the Water Transfer Connection 208629 is a fundamental component that supports the thermal management of the engine, contributing to the durability and performance of the entire system.

-

Alma Hillier, Fundamentals of Motor Vehicle Technology Book 1 6th Edition, Oxford University Press, 2014.

↩ -

Haoran Hu, Rudy Smaling, and Simon Baseley, Heavy-Duty Wheeled Vehicles, SAE International, 2014.

↩ -

Tigran Parikyan Ed, Advances in Engine and Powertrain Research and Technology, Springer Nature, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.