This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

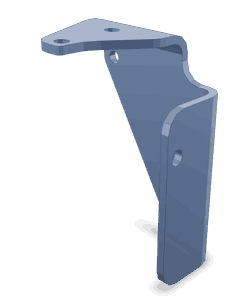

The Water Tube Bracket, identified by Part #2863193, is a component manufactured by Cummins, a leading name in the commercial truck industry. This bracket plays a significant role in the cooling system of heavy-duty truck engines, ensuring the efficient operation of the engine by supporting the water tubes. Cummins is renowned for its commitment to quality and innovation in engine component manufacturing, making this part a reliable choice for maintaining engine efficiency and longevity 1.

Function and Operation

The Water Tube Bracket is integral to the engine’s cooling system. It provides structural support to the water tubes, which are responsible for circulating coolant throughout the engine. By securely holding the water tubes in place, the bracket ensures that coolant flows efficiently through the engine, aiding in the dissipation of heat generated during operation. This consistent and reliable coolant flow is vital for maintaining optimal engine temperature, which in turn contributes to the engine’s overall performance and durability 2.

Key Features

The design and material characteristics of the Water Tube Bracket are tailored to meet the demanding requirements of heavy-duty truck engines. Crafted from high-quality materials, the bracket exhibits exceptional durability, capable of withstanding the harsh conditions within an engine environment. Its precision engineering ensures a perfect fit with Cummins engines, promoting efficient coolant circulation. The bracket’s design also incorporates features that enhance its compatibility and ease of installation, making it a valuable component for engine maintenance and upgrades.

Benefits

Incorporating the Water Tube Bracket into an engine’s cooling system offers several advantages. It enhances engine cooling efficiency by ensuring that the water tubes are properly supported and aligned, which facilitates optimal coolant flow. This efficient coolant circulation helps in reducing the risk of coolant leaks, which can lead to engine overheating and potential damage. Furthermore, by maintaining consistent engine temperatures, the bracket contributes to improved overall engine performance and longevity, making it a beneficial component for heavy-duty truck operations.

Installation and Maintenance

Proper installation of the Water Tube Bracket is crucial for its effective function. It is recommended to follow specific torque specifications and alignment procedures to ensure the bracket is securely fastened and correctly positioned. Regular maintenance, including inspections for wear or damage, is also important to keep the bracket in optimal condition. This proactive approach to maintenance helps in identifying potential issues early, ensuring the continued efficiency of the engine’s cooling system.

Troubleshooting Common Issues

Common problems associated with the Water Tube Bracket may include cracks or misalignment. These issues can affect the bracket’s ability to support the water tubes effectively, potentially leading to inefficient coolant flow or leaks. To address these problems, it is advisable to conduct a thorough inspection of the bracket for any signs of damage. If cracks or misalignment are detected, the bracket should be replaced or repaired as necessary to restore the cooling system’s efficiency and prevent further engine complications.

Cummins Overview

Cummins Inc. has a rich history in the commercial truck industry, known for its extensive product range and commitment to quality and innovation. The company’s engine components, including the Water Tube Bracket, are designed with precision and durability in mind, reflecting Cummins’ dedication to enhancing engine performance and reliability. Cummins’ reputation in the industry is built on its ability to deliver high-quality, innovative solutions that meet the evolving needs of heavy-duty truck engines.

Compatibility with Cummins Engines

The Water Tube Bracket part number 2863193, manufactured by Cummins, is designed to be compatible with a range of Cummins engines. This part is integral in the assembly of the engine’s cooling system, ensuring proper alignment and support for the water tubes.

QSK60 and CM850 Engines

The Water Tube Bracket part 2863193 is specifically engineered to fit the QSK60 and CM850 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications such as marine and industrial settings. The bracket’s design ensures that the water tubes are securely fastened, facilitating efficient heat transfer and maintaining optimal engine temperature.

MCRS Engines

Similarly, the MCRS engines also benefit from the use of the Water Tube Bracket part 2863193. This part is crucial in maintaining the structural integrity of the cooling system within these engines. The bracket’s precision-engineered fit guarantees that the water tubes are properly positioned, which is essential for the engine’s cooling efficiency and overall performance.

Grouping of Engines

The QSK60 and CM850 engines, while distinct in their applications, share a commonality in their cooling system design, which necessitates the use of the Water Tube Bracket part 2863193. This part’s compatibility with both engines underscores its versatility and importance in ensuring the engines’ operational efficiency.

The MCRS engines, on the other hand, also require this bracket for their cooling systems, highlighting the part’s critical role across different engine types. The bracket’s design is such that it can be adapted to fit the specific requirements of each engine model, ensuring a seamless integration and reliable performance.

Role of Part 2863193 Water Tube Bracket in Engine Systems

The Water Tube Bracket, identified by part number 2863193, is an essential component in the integration and functionality of various engine systems. Its primary function is to securely mount and align the water tube, which is a conduit for coolant circulation within the engine.

Integration with the Connection

The Water Tube Bracket interfaces directly with the connection points on the engine block or cylinder head. This bracket ensures that the water tube is correctly positioned and tightly secured, preventing any coolant leaks that could arise from improper alignment or fastening. The secure attachment facilitated by the bracket is vital for maintaining the integrity of the coolant pathway, which is essential for efficient heat dissipation from the engine components.

Functionality with the Auxiliary Cooling Outlet

In systems equipped with an auxiliary cooling outlet, the Water Tube Bracket plays a significant role. This outlet is often used for additional cooling requirements, such as for turbochargers, intercoolers, or other high-temperature components. The bracket ensures that the water tube is correctly routed to the auxiliary cooling outlet, allowing for effective coolant flow to these critical areas. This routing is essential for maintaining optimal operating temperatures and preventing overheating, which can lead to engine damage or reduced performance.

By ensuring proper alignment and secure mounting of the water tube, the Water Tube Bracket contributes to the overall efficiency and reliability of the engine’s cooling system. Its role in connecting and routing coolant to various engine components underscores its importance in maintaining engine health and performance.

Conclusion

The Water Tube Bracket part number 2863193 is a critical component in the cooling systems of Cummins engines, ensuring efficient coolant circulation and maintaining optimal engine temperature. Its compatibility with various Cummins engine models, including the QSK60, CM850, and MCRS engines, highlights its versatility and importance in heavy-duty applications. Proper installation, maintenance, and timely troubleshooting of this part are essential for the continued efficiency and reliability of the engine’s cooling system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.