This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

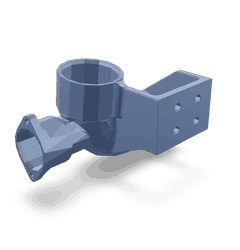

The Water Transfer Connection 2866810 is a component manufactured by Cummins, a prominent entity in the automotive and heavy-duty truck industry. This part is essential for the efficient operation of commercial trucks, particularly in maintaining the cooling system’s functionality. Cummins is recognized for its dedication to quality and innovation, ensuring that its components, like the Water Transfer Connection 2866810, meet the stringent demands of commercial trucking.

Purpose and Function

The Water Transfer Connection 2866810 facilitates the transfer of coolant between various components in the truck’s cooling system. Its design allows for a seamless flow of coolant, which is vital for dissipating heat generated by the engine. This ensures that the engine operates within optimal temperature ranges, thereby enhancing overall performance and longevity 1.

Key Features

The Water Transfer Connection 2866810 is characterized by several key features that contribute to its effectiveness. It is constructed from durable materials, ensuring resistance to corrosion and wear. The design incorporates precise engineering to ensure a secure fit and efficient coolant transfer. Additionally, it may include unique characteristics such as enhanced sealing mechanisms to prevent leaks and maintain system integrity 2.

Benefits

Incorporating the Water Transfer Connection 2866810 into a truck’s cooling system offers several advantages. It promotes improved coolant flow, which is crucial for effective heat management. This, in turn, provides enhanced engine protection by maintaining consistent operating temperatures. Furthermore, the part’s robust construction and design contribute to increased reliability, even under demanding operating conditions typical in commercial trucking.

Installation and Compatibility

Proper installation of the Water Transfer Connection 2866810 is crucial for ensuring its effectiveness. It should be installed according to the manufacturer’s guidelines to guarantee a secure fit and optimal performance. This part is designed to be compatible with various Cummins engine models, ensuring versatility across different applications. It is also engineered to integrate seamlessly with other relevant systems, enhancing overall compatibility.

Maintenance and Troubleshooting

Routine maintenance of the Water Transfer Connection 2866810 is important for ensuring its longevity and performance. Regular inspections for signs of wear or damage, as well as ensuring all connections are secure, can help prevent issues. Common problems may include leaks or reduced coolant flow, which can often be addressed by tightening connections or replacing worn components. Following the manufacturer’s maintenance recommendations can help mitigate these issues.

Performance in Extreme Conditions

The Water Transfer Connection 2866810 is designed to perform reliably under a range of conditions, including extreme temperature variations and high-stress environments. Its durable construction and precise engineering allow it to withstand the rigors of heavy-duty applications, ensuring consistent coolant transfer and engine protection even in the most demanding scenarios.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has built a reputation for innovation, quality, and reliability. The company’s commitment to advancing technology and meeting the needs of its customers is evident in its wide range of automotive components, including the Water Transfer Connection 2866810.

Application in Cummins Engines

The Water Transfer Connection part 2866810, manufactured by Cummins, is a critical component in the cooling systems of several Cummins engine models. This part is designed to facilitate the transfer of water between different sections of the engine’s cooling system, ensuring efficient heat dissipation and maintaining optimal operating temperatures.

Application in QSK60 Engines

In the QSK60 series, the Water Transfer Connection part 2866810 is integral to the engine’s cooling architecture. It connects various cooling passages, ensuring that water flows seamlessly between the engine block, cylinder heads, and other critical components. This part’s precision engineering helps in maintaining the engine’s thermal efficiency, which is crucial for the high-performance demands of the QSK60 engines.

Application in CM850 Engines

For the CM850 engines, the Water Transfer Connection part 2866810 plays a pivotal role in the engine’s cooling system. This part ensures that water is efficiently circulated throughout the engine, providing consistent cooling to the combustion chambers and other heat-generating parts. The design of this component is such that it can withstand the high pressures and temperatures typical of the CM850 engines, contributing to the engine’s longevity and reliability.

Application in MCRS Engines

In the MCRS engines, the Water Transfer Connection part 2866810 is essential for maintaining the engine’s cooling efficiency. This part connects the water passages in the engine block and cylinder heads, ensuring that the cooling system operates smoothly. The robust construction of this component allows it to handle the demanding conditions of the MCRS engines, providing a reliable connection that supports the engine’s overall performance.

Common Features Across Engines

Across the QSK60, CM850, and MCRS engines, the Water Transfer Connection part 2866810 shares common features that make it suitable for these applications. These features include:

- Precision Manufacturing: Ensuring a perfect fit and reliable performance.

- Durability: Constructed to withstand high pressures and temperatures.

- Efficiency: Designed to facilitate smooth water flow, enhancing the engine’s cooling efficiency.

By integrating this part into their cooling systems, Cummins ensures that the engines operate within optimal temperature ranges, thereby enhancing performance and reliability.

Role of Part 2866810 Water Transfer Connection in Engine Systems

In engine systems, the water transfer connection, specifically part 2866810, serves as a pivotal interface facilitating the movement of coolant between various components. This part is integral to maintaining optimal engine temperature and ensuring efficient operation of the cooling system.

Integration with Plumbing

The water transfer connection is designed to integrate seamlessly with the engine’s plumbing system. It acts as a conduit, allowing coolant to flow from the water pump to other critical areas such as the radiator, heater core, and various engine blocks. This ensures that all parts of the engine receive consistent cooling, preventing overheating and potential damage. The connection point must be secure to avoid leaks, which could lead to inefficient cooling and increased engine wear.

Interaction with Thermostat Housing

Another significant component that the water transfer connection interfaces with is the thermostat housing. The thermostat housing contains the thermostat, which regulates the flow of coolant based on the engine’s temperature. The water transfer connection ensures that coolant reaches the thermostat housing efficiently. Once the engine reaches the optimal operating temperature, the thermostat opens, allowing coolant to circulate through the engine block and cylinder head, dissipating heat effectively. This interaction is essential for maintaining the engine’s thermal stability and performance.

Conclusion

The Water Transfer Connection 2866810 by Cummins is a vital component in the cooling systems of commercial trucks and various Cummins engine models. Its role in facilitating efficient coolant flow ensures that engines operate within optimal temperature ranges, enhancing performance and reliability. The part’s durable construction, precise engineering, and compatibility with multiple engine models make it a reliable choice for maintaining the cooling efficiency of heavy-duty engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.