This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

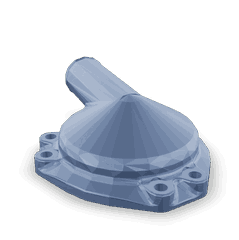

The Cummins 2881586 Water Transfer Connection is a component designed for use in commercial trucks. It facilitates the transfer of coolant within the engine cooling system, ensuring that the engine operates within optimal temperature ranges. This part is integral to maintaining the efficiency and reliability of the truck’s engine, particularly under demanding operational conditions 1.

Basic Concepts of Water Transfer Connection

Water transfer connections in commercial trucks are vital components of the cooling system. They enable the circulation of coolant between different parts of the engine and the radiator. This circulation helps dissipate heat generated during engine operation, preventing overheating and potential damage to engine components. The effectiveness of these connections directly influences the overall performance and longevity of the engine 2.

Purpose of the Cummins 2881586 Water Transfer Connection

The Cummins 2881586 Water Transfer Connection plays a specific role in the engine cooling system by ensuring efficient coolant flow. It connects various coolant passages within the engine, allowing for uniform distribution of coolant. This uniform distribution helps maintain consistent engine temperatures, enhancing the engine’s performance and durability 3.

Key Features

The Cummins 2881586 Water Transfer Connection is characterized by its robust design and the use of high-quality materials. It is engineered to withstand the high pressures and temperatures typical of commercial truck engines. The connection features precise machining and durable construction, which contribute to its reliable performance. Additionally, its design ensures a secure fit within the engine assembly, minimizing the risk of leaks 4.

Benefits

Using the Cummins 2881586 Water Transfer Connection offers several advantages. It contributes to improved cooling efficiency, which is crucial for maintaining engine performance under various operating conditions. The connection’s durable construction ensures long-term reliability, reducing the need for frequent replacements. Moreover, its efficient design helps in maintaining optimal engine temperatures, which can lead to enhanced fuel efficiency and reduced maintenance costs 1.

Installation Process

Installing the Cummins 2881586 Water Transfer Connection requires careful attention to detail. The process involves disconnecting the old connection, cleaning the mating surfaces, and ensuring that all gaskets and seals are in good condition. The new connection should be aligned properly with the coolant passages and secured in place. It is important to use the correct torque specifications when tightening any fasteners to prevent damage and ensure a secure fit 2.

Common Issues and Troubleshooting

Common issues with the Cummins 2881586 Water Transfer Connection may include leaks, blockages, or corrosion. Leaks can often be traced to improper installation or worn gaskets and seals. Blockages may result from debris within the cooling system, necessitating a thorough flush. Corrosion can be addressed by replacing affected components and ensuring that the cooling system is properly maintained. Regular inspections can help identify and resolve these issues promptly 3.

Maintenance Tips

To ensure the optimal performance and longevity of the Cummins 2881586 Water Transfer Connection, regular maintenance is recommended. This includes periodic inspections for signs of wear, corrosion, or leaks. Cleaning the connection and its surrounding areas can prevent the buildup of debris that may obstruct coolant flow. Additionally, ensuring that the cooling system is free of contaminants and operates at the correct pressure can contribute to the efficient functioning of the connection 4.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive industry. The company’s product offerings cater to various sectors, including commercial trucking, construction, agriculture, and power generation, among others 1.

Role of Part 2881586 Water Transfer Connection in Engine Systems

The part 2881586 Water Transfer Connection is an integral component in the efficient operation of several engine systems, particularly in turbocharged and aftercooled setups.

In turbocharged engines, the Water Transfer Connection facilitates the circulation of coolant between the turbocharger and the engine’s cooling system. This helps in maintaining optimal temperatures for the turbocharger, which is vital for its longevity and performance. The connection ensures that the heat generated by the turbocharger is effectively managed, preventing overheating and potential damage 2.

When integrated with an aftercooler, the Water Transfer Connection plays a significant role in enhancing the efficiency of the cooling process. Aftercoolers are designed to reduce the temperature of the compressed air from the turbocharger before it enters the engine’s combustion chambers. The Water Transfer Connection ensures a consistent flow of coolant through the aftercooler, which is essential for effective heat dissipation. This results in denser air entering the engine, improving combustion efficiency and overall engine performance 3.

Conclusion

The Cummins 2881586 Water Transfer Connection is a key element in the thermal management of turbocharged engines, especially when paired with aftercoolers. Its role in facilitating the efficient transfer of coolant helps in maintaining the optimal operating temperatures of critical engine components, thereby enhancing performance and reliability 4.

-

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩ ↩ ↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ ↩ ↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ ↩ ↩ -

Harrison, M. (2004). Controlling Noise and Vibration in Road Vehicles. SAE International.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.