This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

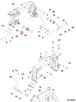

The Cummins 2886179 Water Transfer Tube is a component designed to facilitate the movement of coolant within the cooling system of heavy-duty trucks. Its role is to ensure efficient heat dissipation from the engine, contributing to the overall performance and longevity of the vehicle’s powertrain 1.

Basic Concepts of Water Transfer Tubes

A Water Transfer Tube is a conduit that allows coolant to circulate between various components of a truck’s cooling system. This circulation is vital for dissipating heat generated by the engine, thus maintaining optimal operating temperatures. The tube’s design and placement are engineered to handle the pressures and temperatures of the coolant as it moves through the system 2.

Purpose of the Cummins 2886179 Water Transfer Tube

The Cummins 2886179 Water Transfer Tube is specifically designed to transfer coolant between the engine and the radiator in heavy-duty trucks. This transfer is crucial for dissipating heat away from the engine, ensuring that the engine operates within its designed temperature range, which is important for efficiency and durability 3.

Key Features

This Cummins part is constructed with materials that can withstand the high temperatures and pressures of the cooling system. It features robust connection points that ensure a secure fit within the system. The tube’s design may include features that enhance coolant flow and reduce the risk of leaks or blockages 4.

Benefits

The Cummins 2886179 Water Transfer Tube offers several advantages, including improved coolant flow which enhances the cooling efficiency of the engine. Its durable construction ensures reliability even under harsh operating conditions, contributing to the overall robustness of the truck’s cooling system 5.

Installation Process

Installing the Cummins 2886179 Water Transfer Tube requires following a series of steps to ensure it is correctly fitted within the cooling system. This process may involve using specific tools to connect the tube to the engine and radiator. It is important to follow manufacturer guidelines to ensure the tube is installed correctly and functions as intended 6.

Troubleshooting Common Issues

Common issues with Water Transfer Tubes can include leaks or blockages. These problems can often be diagnosed through visual inspection or by monitoring the cooling system’s performance. Resolving these issues may involve repairing or replacing the tube, ensuring that the cooling system continues to operate efficiently 7.

Maintenance Tips

Regular maintenance of the Cummins 2886179 Water Transfer Tube is important for its longevity and efficient operation. This may include periodic inspections for signs of wear or damage, and cleaning the tube to remove any deposits that could impede coolant flow. Adhering to a maintenance schedule can help prevent issues and ensure the cooling system operates effectively 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the industry, Cummins is known for its commitment to quality and innovation in diesel engine technology and related components for commercial vehicles.

Water Transfer Tube (Part 2886179) Compatibility with Cummins Engines

The Water Transfer Tube (part number 2886179) manufactured by Cummins is designed to fit seamlessly with a range of Cummins engines, ensuring efficient coolant flow and optimal engine performance. This part is integral to the cooling system of these engines, facilitating the transfer of water between different components.

VTA903 and CM2250 Engines

The VTA903 and CM2250 engines are part of Cummins’ lineup that benefits from the Water Transfer Tube. This component is engineered to integrate smoothly with the cooling systems of these engines, providing a reliable pathway for coolant circulation. The design ensures that the coolant is evenly distributed, preventing overheating and maintaining the engine’s operational efficiency.

V105 Engine

The V105 engine also utilizes the Water Transfer Tube (part number 2886179) as a critical part of its cooling system. This tube is specifically designed to fit the V105 engine’s architecture, ensuring that the coolant is effectively transferred across various engine components. The precision engineering of this part guarantees that it will perform optimally within the V105 engine’s cooling system, contributing to the engine’s longevity and performance.

Integration and Functionality

The Water Transfer Tube is meticulously crafted to fit into the cooling systems of the VTA903, CM2250, and V105 engines. Its design allows for a seamless connection with the engine’s coolant pathways, ensuring that the coolant is efficiently circulated. This part’s compatibility with these engines underscores Cummins’ commitment to providing high-quality, reliable components that enhance engine performance and durability.

Role of Part 2886179 Water Transfer Tube in Engine Systems

The part 2886179 Water Transfer Tube is an essential component in the efficient operation of engine systems, particularly in ensuring the proper circulation of coolant. This component is integral to maintaining optimal engine temperature and preventing overheating.

Interaction with the Manifold

The Water Transfer Tube interfaces directly with the engine manifold, a component responsible for distributing the air-fuel mixture into the combustion chambers. The tube’s role here is to facilitate the transfer of coolant to and from the manifold. This ensures that the manifold remains at a stable temperature, which is vital for consistent engine performance and durability. The tube’s precise fit and secure connection help maintain a sealed coolant pathway, minimizing the risk of leaks that could lead to engine damage.

Coolant Circulation in the Engine

In conjunction with the water pump and thermostat, the Water Transfer Tube plays a significant role in the overall coolant circulation system. It helps transport coolant from the engine block to the radiator and back, ensuring that heat is effectively dissipated. This continuous circulation is essential for maintaining the engine’s operating temperature within safe limits, thereby enhancing the engine’s efficiency and longevity.

Integration with Cooling System Components

Beyond its direct interaction with the manifold, the Water Transfer Tube also connects to other critical cooling system components such as the radiator, thermostat housing, and various hoses. This integration ensures a cohesive coolant flow throughout the engine system. The tube’s design allows for efficient coolant transfer, reducing the likelihood of hotspots and ensuring even temperature distribution across the engine.

Enhancing Engine Reliability

By ensuring consistent coolant flow, the Water Transfer Tube contributes to the overall reliability of the engine. It helps prevent scenarios where inadequate cooling could lead to warped cylinder heads, cracked engine blocks, or other severe damage. The tube’s durable construction and precise engineering make it a dependable component in the engine’s cooling system.

Conclusion

In summary, the Cummins 2886179 Water Transfer Tube is a vital element in the engine’s cooling infrastructure, working in tandem with the manifold and other cooling components to maintain engine health and performance. Its role in facilitating efficient coolant circulation is crucial for the engine’s longevity and operational efficiency.

-

Reif, K. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ -

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for F3.8 CM2350 F120B, Bulletin Number 5411238.

↩ -

Reif, K. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for F3.8 CM2350 F120B, Bulletin Number 5411238.

↩ -

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.