This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 2886180 Water Transfer Tube is a vital component in the cooling systems of heavy-duty trucks. It facilitates the transfer of coolant between the engine and the radiator, ensuring optimal engine temperature and efficient cooling system operation.

Basic Concepts of Water Transfer Tubes

A water transfer tube serves as a conduit within the cooling system, allowing coolant to flow between the engine and the radiator. This component is essential for dissipating heat generated by the engine, preventing overheating. The tube’s design and placement are crucial for effective coolant circulation, contributing to the engine’s stability and performance 1.

Purpose of the Cummins 2886180 Water Transfer Tube

The Cummins 2886180 Water Transfer Tube is engineered to enhance coolant transfer in heavy-duty trucks. It provides a direct pathway for coolant to travel from the engine to the radiator and back, ensuring the engine maintains a consistent operating temperature through efficient coolant circulation 2.

Key Features

This Cummins part is characterized by its robust design and the use of high-quality materials. These features contribute to its durability and effectiveness in high-stress environments typical of heavy-duty truck operations. The tube’s construction is tailored to withstand the pressures and temperatures associated with engine cooling systems, ensuring reliable performance over time.

Benefits

The implementation of the Cummins 2886180 Water Transfer Tube in a truck’s cooling system offers several advantages. It contributes to improved coolant flow, enhancing the engine’s thermal management. This leads to better engine protection against overheating and reduces the risk of coolant system failures. Additionally, the tube’s design and materials contribute to the increased reliability of the cooling system, supporting the engine’s longevity and performance.

Installation and Compatibility

Proper installation of the Cummins 2886180 Water Transfer Tube is vital for ensuring its effective operation within the cooling system. The process involves securing the tube in place using appropriate tools and equipment, following manufacturer guidelines to maintain system integrity. Compatibility with various Cummins engine models is a key consideration, ensuring that the tube fits seamlessly into the existing cooling system architecture.

Troubleshooting and Maintenance

Regular maintenance and timely troubleshooting are important for the Cummins 2886180 Water Transfer Tube to function optimally. Common issues such as leaks or blockages can be identified through routine inspections and addressed promptly to prevent system failures. Maintenance practices may include checking for signs of wear or damage, ensuring proper connections, and verifying the tube’s alignment within the system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and a broad portfolio of products, Cummins has established a strong reputation in the automotive industry for quality, reliability, and performance. The company’s commitment to excellence is reflected in its extensive range of components, including the Cummins 2886180 Water Transfer Tube, designed to meet the demanding requirements of heavy-duty applications.

Compatibility with Specific Engines

VTA903 and CM2250 Engines

The Water Transfer Tube 2886180 is compatible with the VTA903 and CM2250 engines. These engines, known for their robust performance and reliability, benefit significantly from the precise engineering of this part. The tube’s design allows for seamless integration into the cooling system architecture of these engines, facilitating effective heat dissipation and maintaining the engine’s efficiency.

V105 Engine

Similarly, the V105 engine also utilizes the Water Transfer Tube 2886180. This engine, recognized for its versatility and strength, integrates this component to enhance its cooling system’s performance. The tube’s role in the V105 engine is crucial for maintaining the engine’s operational integrity, especially under demanding conditions.

Importance of the Water Transfer Tube

In all these engines, the Water Transfer Tube 2886180 plays a pivotal role in the cooling system. It ensures that the coolant is distributed evenly, which is essential for preventing hotspots and ensuring that the engine operates within its optimal temperature range. This part’s compatibility with the VTA903, CM2250, and V105 engines underscores its versatility and importance in maintaining engine health and performance.

Role of Part 2886180 Water Transfer Tube in Engine Systems

The part 2886180 Water Transfer Tube is instrumental in facilitating the efficient movement of water within engine systems. It is designed to connect various components, ensuring a seamless flow of water for cooling and other operational purposes.

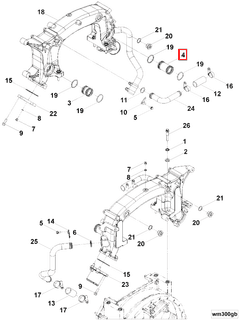

Integration with the Manifold

When integrated with the manifold, the Water Transfer Tube plays a significant role in distributing water to different sections of the engine. The manifold, which is responsible for directing the flow of air or fluids to the engine’s cylinders, relies on the Water Transfer Tube to maintain consistent water pressure and flow. This ensures that each cylinder receives the necessary cooling, which is essential for optimal engine performance and longevity.

Interaction with the Water Pump

The Water Transfer Tube also works in conjunction with the water pump. The water pump circulates coolant throughout the engine, and the tube acts as a conduit, guiding the coolant from the pump to the manifold and other critical areas. This interaction is vital for maintaining the engine’s temperature within safe operating limits, preventing overheating, and ensuring that the coolant reaches all necessary components efficiently.

Enhancing Cooling Efficiency

By providing a direct and unobstructed path for water flow, the Water Transfer Tube enhances the overall cooling efficiency of the engine system. It minimizes restrictions and potential leak points, which can otherwise lead to inefficient cooling and increased wear on engine components.

Supporting Thermal Management

In addition to cooling, the Water Transfer Tube supports the engine’s thermal management system. It helps in evenly distributing heat across the engine, which is crucial for maintaining consistent performance under varying operational conditions. This even distribution prevents hot spots, which can lead to warping or damage to engine parts.

Facilitating Maintenance and Repairs

The design of the Water Transfer Tube also aids in maintenance and repair processes. Its straightforward integration with other components allows for easier access during routine checks and replacements. This can significantly reduce downtime and make maintenance procedures more efficient.

Conclusion

The Cummins 2886180 Water Transfer Tube is a key component in the engine’s water management system, ensuring efficient coolant distribution, enhanced cooling efficiency, and reliable thermal management. Its robust design, compatibility with various Cummins engines, and role in maintaining optimal engine temperature make it an essential part of heavy-duty truck cooling systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.