This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

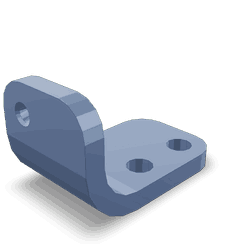

The Water Tube Bracket, identified by Part #2886388, is a component manufactured by Cummins, a well-established name in the automotive industry. This Cummins part plays a significant role in the cooling systems of heavy-duty truck engines. Its design and functionality are tailored to meet the demanding requirements of commercial and industrial applications, ensuring reliable performance under various operating conditions 1.

Function and Operation

This part serves a pivotal role in the engine’s cooling system by securely supporting the water tubes. These tubes are integral to the circulation of coolant throughout the engine, facilitating the transfer of heat away from critical components. By maintaining the structural integrity and alignment of the water tubes, the bracket contributes to efficient heat dissipation, which is vital for maintaining optimal engine operating temperatures and preventing overheating 2.

Key Features

The Water Tube Bracket is characterized by its robust design and high-quality materials, which are selected to withstand the harsh environments typical of heavy-duty truck operations. Precision engineering ensures that the bracket fits snugly and securely within the engine assembly, promoting stability and reliability. Its compatibility with Cummins engines is a testament to the meticulous design process, ensuring seamless integration and performance 3.

Benefits

Incorporating the Water Tube Bracket into an engine’s cooling system offers several advantages. It enhances engine performance by ensuring consistent and efficient cooling, which is crucial for maintaining engine efficiency and longevity. The bracket’s durable construction and precise fit contribute to improved reliability, reducing the likelihood of coolant leaks or system failures. Additionally, its design may lead to reduced maintenance requirements, offering cost savings and convenience for fleet operators 4.

Installation and Compatibility

Proper installation of the Water Tube Bracket is crucial for ensuring its effectiveness and the overall efficiency of the engine’s cooling system. Installation procedures should follow manufacturer guidelines to ensure correct alignment and secure fastening. Specific requirements or considerations for Cummins engines may include torque specifications for fasteners and verification of compatibility with the engine model to ensure optimal performance and longevity 1.

Maintenance and Troubleshooting

Regular inspection and maintenance of the Water Tube Bracket are recommended to ensure its continued optimal performance. This includes checking for signs of wear, corrosion, or damage that could affect its ability to support the water tubes effectively. Common issues may include misalignment or loosening of the bracket, which can be addressed by re-securing or replacing the bracket as necessary. Prompt attention to these issues can prevent more significant problems within the engine’s cooling system 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive industry. The company’s extensive product offerings and commitment to excellence underpin the manufacturing and quality standards of components like the Water Tube Bracket, ensuring they meet the rigorous demands of heavy-duty applications 3.

Role of Part 2886388 in Engine Systems

The 2886388 is an essential component in the arrangement of various engine systems, particularly those involving the aftercooler and turbocharger.

In systems equipped with an aftercooler, the Water Tube Bracket secures the water tubes that facilitate the transfer of coolant. This ensures efficient heat exchange between the compressed air from the turbocharger and the coolant, which is vital for optimizing the air temperature before it enters the engine’s combustion chamber. Proper mounting and alignment provided by the bracket contribute to the stability and effectiveness of the aftercooling process.

When integrated with a turbocharger system, the Water Tube Bracket plays a role in maintaining the structural integrity of the water tubes that may be used for intercooling purposes. This helps in managing the temperature of the air charged by the turbocharger, thereby enhancing engine performance and reliability.

Overall, the Water Tube Bracket ensures that the water tubes are correctly positioned and supported, which is important for the efficient operation of the cooling systems associated with turbocharged engines 4.

Conclusion

The Water Tube Bracket (Part #2886388) is a critical component in the cooling systems of heavy-duty truck engines, offering robust support for water tubes to ensure efficient heat dissipation and engine performance. Its design, compatibility with Cummins engines, and the benefits it provides in terms of reliability and maintenance make it a valuable part for commercial and industrial applications. Proper installation, regular maintenance, and understanding its role in engine systems are essential for maximizing its effectiveness and longevity.

-

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ ↩ -

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩ ↩ -

Reif, Konrad. Diesel Engine Management Systems and Components. Springer, 2014.

↩ ↩ -

Osgood, Libby, Cameron, Gayla, and Christensen, Emma. Engineering Mechanics: Statics. Creative Commons, 2024.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.