This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

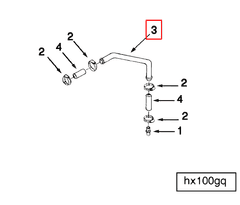

The Water Makeup Tube (Part #3000322) by Cummins is a component designed to facilitate the replenishment of coolant within the engine cooling system of commercial trucks. Its role is significant in ensuring the efficient operation and longevity of the engine by maintaining optimal coolant levels 1.

Basic Concepts and Functionality

Water makeup tubes are integral to the engine cooling system, primarily responsible for the automatic replenishment of coolant as it is lost through evaporation or leakage. These tubes function by allowing fresh coolant to enter the system when the coolant level drops below a certain threshold. This process helps maintain the coolant at the appropriate level, ensuring consistent cooling performance and preventing engine overheating 2.

Purpose of the Water Makeup Tube

The Water Makeup Tube (Part #3000322) specifically serves to maintain the coolant level within the truck’s engine cooling system. By ensuring that the coolant level remains consistent, it plays a role in the cooling system by facilitating efficient heat dissipation from the engine. This consistent coolant level contributes to stable engine temperature, which is vital for engine performance and longevity 3.

Key Features

This Cummins part is engineered with specific features to enhance its performance and durability. It is constructed from high-quality materials resistant to corrosion and high temperatures, ensuring longevity and reliability. The design of the tube includes precise fittings and connections to ensure a secure and leak-free integration within the cooling system 4.

Benefits

Utilizing the Water Makeup Tube (Part #3000322) offers several benefits. It contributes to improved engine cooling efficiency by ensuring that the coolant level remains optimal. This consistent coolant level reduces the risk of engine overheating, which can lead to severe engine damage. Additionally, it enhances overall engine performance by maintaining stable operating temperatures.

Installation and Integration

Proper installation of the Water Makeup Tube (Part #3000322) is crucial for its effective function within the truck’s cooling system. It should be installed according to the manufacturer’s guidelines to ensure secure and leak-free connections. Specific considerations include ensuring that all connections are tight and that the tube is correctly positioned to allow for the free flow of coolant.

Troubleshooting and Maintenance

Common issues with the Water Makeup Tube (Part #3000322) may include leaks or blockages. Regular inspection and maintenance can help identify and address these issues promptly. Maintenance tips include checking for signs of wear or damage, ensuring all connections are secure, and monitoring coolant levels to ensure they remain within the optimal range.

Cummins Overview

Cummins is a renowned manufacturer with a long-standing reputation in the automotive industry for producing high-quality components. The company’s commitment to innovation and quality is evident in its wide range of products, including the Water Makeup Tube (Part #3000322), which is designed to meet the demanding requirements of commercial truck engines.

Water Makeup Tube (Part 3000322) in Cummins Engines

The Water Makeup Tube, identified by part number 3000322, is a critical component in the cooling systems of various Cummins engines. This part is integral to maintaining the optimal operating temperature of the engine by ensuring a consistent supply of coolant.

N14 MECHANICAL

In the N14 MECHANICAL engine, the Water Makeup Tube plays a vital role in the coolant circulation system. It connects the coolant reservoir to the engine block, facilitating the flow of coolant to areas that may experience temperature fluctuations. This ensures that the engine operates within its specified temperature range, preventing overheating and potential damage.

NH/NT 855

Similarly, in the NH/NT 855 engines, the Water Makeup Tube is essential for maintaining the coolant levels and pressure within the system. This part ensures that the coolant is adequately distributed throughout the engine, which is crucial for efficient heat dissipation. The NH/NT 855 engines, known for their robust performance, rely on this component to sustain their operational integrity over extended periods.

The Water Makeup Tube is designed to withstand the high pressures and temperatures encountered in these engines, ensuring durability and reliability. Its precise fit and function are critical for the overall performance and longevity of the engine.

Understanding the Role of Part 3000322 Water Makeup Tube in Engine Systems

The Part 3000322 Water Makeup Tube is an essential component in maintaining the efficiency and reliability of various engine systems. Its primary function is to ensure a consistent water level within the radiator, which is vital for the proper operation of the radiator cooling system.

Integration with Radiator Components

-

Radiator and Mounting: The Water Makeup Tube works in conjunction with the radiator and its mounting system. It ensures that the radiator remains filled to the optimal level, allowing for efficient heat exchange.

-

Radiator Cooling System: Within the radiator cooling system, the Water Makeup Tube plays a significant role. It replenishes the water lost through evaporation or leaks, maintaining the coolant level necessary for effective heat dissipation.

-

Heat Exchanger: The tube is also integral to the heat exchanger’s function. By keeping the coolant level stable, it ensures that the heat exchanger can efficiently transfer heat away from the engine, preventing overheating.

-

Radiator Cooling: In the context of radiator cooling, the Water Makeup Tube ensures that the cooling process is uninterrupted. It provides a steady supply of water to the radiator, which is essential for maintaining the engine’s operating temperature within safe limits.

-

Water Fill Tube: As a water fill tube, it directly contributes to the radiator’s capacity to hold coolant. This is particularly important during periods of high engine load or in hot operating conditions, where the demand for cooling is greater.

Supporting Engine Efficiency

The consistent water level maintained by the Water Makeup Tube supports the overall efficiency of the engine. By ensuring that the radiator and cooling system operate under optimal conditions, it helps in:

- Reducing Thermal Stress: Consistent coolant levels help in reducing thermal stress on engine components, prolonging their lifespan.

- Enhancing Performance: Proper cooling allows the engine to perform at its peak, without the risk of overheating.

- Preventing Damage: By maintaining the right coolant level, the Water Makeup Tube helps in preventing damage to the engine and other critical components.

Conclusion

In summary, the Part 3000322 Water Makeup Tube is a key component in the intricate network of parts that make up an engine’s cooling system. Its role in ensuring a stable water level within the radiator is fundamental to the efficient operation and longevity of the engine.

-

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.