This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Water Inlet Tube 3001605 is a component manufactured by Cummins, a prominent name in the automotive and heavy-duty truck industry. This part is designed to serve a specific function within the cooling system of heavy-duty trucks. Its primary role is to facilitate the efficient flow of coolant into the engine, thereby contributing to the overall cooling process.

Function and Operation

The Water Inlet Tube 3001605 operates by directing coolant flow into the engine’s cooling system. It is positioned to allow coolant to enter the engine block, where it absorbs heat generated by the combustion process. The coolant then circulates through the engine, picking up additional heat before returning to the radiator to be cooled. This continuous cycle helps maintain optimal engine temperature, ensuring efficient operation and longevity 1.

Key Features

This Cummins part is constructed from high-quality materials that offer durability and resistance to corrosion. Its design includes precise fittings and connections that ensure a secure and leak-free installation. The tube’s material and construction are tailored to withstand the high pressures and temperatures typical of heavy-duty engine environments. Additionally, the design may incorporate features that enhance coolant flow, such as smooth internal surfaces and optimized geometry 2.

Benefits

The use of the Water Inlet Tube 3001605 in the engine cooling system offers several advantages. It contributes to improved coolant flow, which enhances the engine’s cooling efficiency. This can lead to better engine protection against overheating and potential damage. Furthermore, efficient cooling can contribute to increased engine efficiency and longevity, as engines operating within their optimal temperature range tend to perform better and last longer 3.

Installation and Compatibility

Proper installation of the Water Inlet Tube 3001605 is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines, which may include specific torque settings for fasteners and recommendations for sealing compounds. Ensuring a proper fit and seal is important to prevent coolant leaks and maintain system integrity. Compatibility information, including specific engine models and systems, should be consulted to ensure the correct application of this component.

Maintenance and Troubleshooting

Regular maintenance of the Water Inlet Tube 3001605 is important to ensure its continued optimal functioning. This may include periodic inspections for signs of wear, corrosion, or leaks. Cleaning the tube and its connections as part of routine engine maintenance can help prevent buildup that might impede coolant flow. Common issues that may arise include leaks or blockages, which can often be addressed by re-sealing connections or cleaning the tube, respectively.

Safety Considerations

When handling, installing, or maintaining the Water Inlet Tube 3001605, it is important to observe safety guidelines. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards. Additionally, ensuring the engine is cool before beginning work can help prevent burns from hot coolant or engine components. Following manufacturer guidelines for installation and maintenance can also contribute to a safe working environment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industry. The company’s product range includes engines and components designed to meet the demanding requirements of various applications, from on-highway trucks to off-highway construction equipment and power generation.

Cummins Water Inlet Tube 3001605 Compatibility with V28 Engines

The Cummins Water Inlet Tube part number 3001605 is designed to fit seamlessly with various V28 engine configurations. This part is integral to the engine’s cooling system, ensuring that coolant flows efficiently from the radiator to the engine block.

V28 Engine Series

- V28-3000 Series

- V28-3500 Series

- V28-4000 Series

These engines are known for their robust performance and reliability, often used in heavy-duty applications such as construction equipment, marine vessels, and industrial machinery. The Water Inlet Tube 3001605 is engineered to meet the specific requirements of these engines, ensuring optimal performance and longevity.

Installation and Functionality

The installation of the Water Inlet Tube 3001605 is straightforward, designed to integrate with the engine’s existing cooling system. It is crucial for maintaining the engine’s operational temperature, preventing overheating, and ensuring efficient heat dissipation.

Compatibility Considerations

When replacing or installing the Water Inlet Tube 3001605, it is essential to verify compatibility with the specific V28 engine model. This ensures that the part fits correctly and functions as intended, avoiding potential issues that could arise from using an incorrect component.

Maintenance and Replacement

Regular maintenance of the Water Inlet Tube 3001605 is recommended to prevent leaks and ensure the cooling system operates efficiently. If any signs of wear or damage are detected, prompt replacement is advised to maintain the engine’s performance and reliability.

Role of Part 3001605 Water Inlet Tube in Engine Systems

The Water Inlet Tube 3001605 is an essential component in the efficient operation of various engine systems, particularly within the cooling system. This component is designed to facilitate the smooth flow of coolant into the radiator, ensuring that the engine maintains optimal operating temperatures.

Integration with the Cooling System

Within the cooling system, the Water Inlet Tube connects to the radiator, allowing coolant to enter from the water fill tube. This connection is vital for the circulation of coolant, which absorbs heat from the engine and transfers it away through the radiator. The tube’s precise fit and secure connection prevent leaks, ensuring that the cooling system operates efficiently.

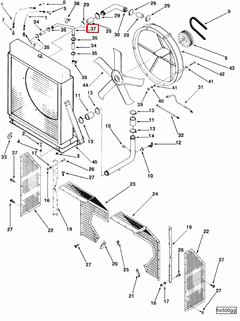

Connection to the Radiator and Base Rail

The Water Inlet Tube is often part of a kit that includes the radiator and base rail. This setup ensures that the tube is correctly aligned with the radiator’s inlet, promoting a seamless flow of coolant. The base rail provides a stable platform for the tube, enhancing the structural integrity of the cooling system.

Role in the Make-Up Line

In systems that utilize a make-up line, the Water Inlet Tube plays a significant role. The make-up line is designed to replenish coolant levels automatically, and the tube ensures that this process is smooth and uninterrupted. This is particularly important in high-performance engines where maintaining consistent coolant levels is essential for peak performance.

Radiator Connection

The tube’s connection to the radiator is a key aspect of its function. It ensures that coolant is directed into the radiator efficiently, allowing for effective heat exchange. The design of the tube minimizes resistance, enhancing the flow of coolant and contributing to the overall efficiency of the cooling system.

Interaction with the Water Fill Tube

The Water Inlet Tube works in conjunction with the water fill tube to maintain coolant levels. When coolant is added to the system, it flows through the water fill tube and into the radiator via the Water Inlet Tube. This interaction is essential for maintaining the correct coolant level, which is crucial for the engine’s thermal management.

Conclusion

The Water Inlet Tube 3001605 is a vital component in the cooling system, facilitating the efficient flow of coolant into the radiator and ensuring that the engine operates within safe temperature ranges. Its integration with various components, including the radiator, base rail, and make-up line, underscores its importance in maintaining the overall health and performance of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.