This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

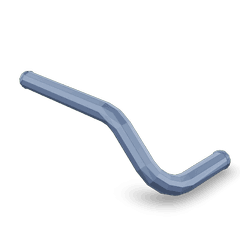

The Water Transfer Tube (Part #3001650) by Cummins is a component designed to facilitate the efficient transfer of coolant within the cooling system of commercial trucks. Its purpose is to ensure that the engine maintains optimal operating temperatures, thereby contributing to the overall performance and longevity of the vehicle 2.

Basic Concepts and Functionality

Water transfer tubes operate on the fundamental principle of fluid dynamics within a truck’s cooling system. These tubes are responsible for directing coolant flow from the engine to the radiator and back, playing a role in dissipating heat generated during engine operation. The efficient circulation of coolant is significant for maintaining engine temperature within specified ranges, which is vital for engine health and performance 1.

Purpose and Role in Truck Operation

This Cummins part is specifically designed to enhance the cooling system’s efficiency in commercial trucks. By ensuring a consistent and reliable flow of coolant, it contributes to stable engine temperatures. This stability is important for efficient engine operation, as it helps prevent overheating, which can lead to engine damage, and ensures that the engine operates within its designed parameters for optimal performance 2.

Key Features

The 3001650 is characterized by several design elements and material choices that enhance its functionality and durability. It is constructed from high-quality materials resistant to corrosion and high temperatures, ensuring longevity and reliability. The tube’s design facilitates smooth coolant flow, minimizing restrictions and enhancing cooling efficiency. Additionally, it is engineered to withstand the demanding conditions typical of commercial truck operations 2.

Benefits

The advantages offered by the 3001650 include improved cooling efficiency, which leads to better engine protection against overheating. Its design and material contribute to increased reliability, even in challenging operating environments. This reliability is important for maintaining vehicle uptime and reducing the risk of engine-related failures 2.

Troubleshooting and Maintenance

Common issues with the 3001650 may include leaks or blockages, which can impair coolant flow and affect engine cooling. Regular inspection and maintenance, such as checking for signs of wear or damage and ensuring proper installation, are recommended to address these issues. Prompt replacement of a faulty tube is advised to maintain optimal cooling system performance 2.

Installation and Compatibility

Proper installation of the 3001650 is important for ensuring its effectiveness and longevity. Installation procedures should follow manufacturer guidelines to avoid common pitfalls that could lead to performance issues. The tube is designed to be compatible with a range of truck models and engine configurations, though specific compatibility details should be verified to ensure proper fit and function 2.

Performance and Efficiency

The design and functionality of the 3001650 contribute to enhanced truck performance and fuel efficiency. By ensuring efficient coolant circulation, it helps maintain engine temperatures that are conducive to optimal operation. This, in turn, can lead to improved fuel efficiency and reduced operating costs, as the engine operates more efficiently within its designed temperature range 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a strong reputation in the automotive industry, Cummins is committed to delivering high-quality components that meet the demanding requirements of commercial vehicle applications. Their products, including the 3001650, are designed with a focus on reliability, performance, and durability 2.

Integration and Functionality

The integration of the Water Transfer Tube into the engine’s cooling system is critical. It connects various coolant passages, ensuring that the coolant circulates efficiently. This part’s placement and design are crucial for maintaining the engine’s thermal balance, preventing localized overheating, and extending the engine’s lifespan 2.

Compatibility and Reliability

Cummins has ensured that the Water Transfer Tube is compatible with a range of engine models. This compatibility is achieved through rigorous testing and design processes, ensuring that the part meets the stringent requirements of Cummins engines. The reliability of this component is a testament to Cummins’ commitment to quality and performance 2.

Maintenance Considerations

When maintaining engines that utilize the Water Transfer Tube, it is essential to inspect this component regularly. Any signs of wear, corrosion, or blockage can significantly impact the engine’s cooling efficiency. Proper maintenance of this part ensures that the engine operates at peak performance and reduces the risk of costly breakdowns 2.

Role of Part 3001650 Water Transfer Tube in Engine Systems

The Water Transfer Tube is an essential component in various engine systems, facilitating efficient thermal management and performance optimization. Here’s how it integrates with the provided components:

Aftercooler Kit and Aftercooler Plumbing

The Water Transfer Tube is pivotal in the aftercooler kit, where it aids in the circulation of coolant through the aftercooler plumbing. This ensures that the compressed air is effectively cooled post-compression, enhancing engine efficiency and reducing the risk of overheating 2.

Air Intake Manifold and Intake Manifold

In systems with an air intake manifold or intake manifold, the Water Transfer Tube assists in maintaining optimal temperatures. By transferring coolant, it helps in regulating the temperature of the air-fuel mixture entering the combustion chamber, which is vital for consistent engine performance 2.

Air Intercooler and Intercooler Air

When integrated with an air intercooler or intercooler air system, the Water Transfer Tube plays a role in dissipating heat from the compressed air. This results in denser air entering the engine, which can lead to improved combustion efficiency and power output 2.

Air Manifold and Air Mounting Intercooler

In configurations involving an air manifold or air mounting intercooler, the Water Transfer Tube ensures that the intercooler remains at an efficient operating temperature. This is achieved by circulating coolant, which absorbs excess heat from the intercooler, thus maintaining the desired air temperature for combustion 2.

Manifold Air Mounting and Manifold Intake

For systems with manifold air mounting or manifold intake, the Water Transfer Tube is instrumental in thermal management. It helps in evenly distributing coolant throughout the manifold, ensuring that the air-fuel mixture is at the ideal temperature before entering the engine cylinders 2.

Mounting Intercooler and MTG. (Mounting)

In setups where the intercooler is mounted using specific mounting hardware (MTG.), the Water Transfer Tube ensures that the coolant flow is uninterrupted and efficient. This is essential for maintaining the intercooler’s effectiveness in reducing the temperature of the intake air 2.

Manifolding Wet

In wet manifolding systems, where coolant is directly involved in the manifolding process, the Water Transfer Tube is crucial for transferring coolant to and from the manifold. This helps in precisely controlling the temperature of the air-fuel mixture, which is critical for engine performance and reliability 2.

Conclusion

Overall, the 3001650 Water Transfer Tube is a key component in ensuring that engine systems operate within their optimal temperature ranges, thereby enhancing performance, efficiency, and longevity. Its integration into various engine components underscores its importance in maintaining engine health and performance across a range of applications 2.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.