This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

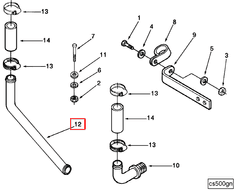

The Cummins 3003185 Water Transfer Tube is a component designed for use in the cooling systems of heavy-duty trucks. Its purpose is to facilitate the circulation of coolant within the engine, ensuring that the engine operates within optimal temperature ranges. This component is significant for maintaining the efficiency and longevity of the engine by playing a role in the cooling system 1.

Basic Concepts of Water Transfer Tubes

A Water Transfer Tube is a conduit that allows coolant to flow between different parts of the engine cooling system. Its function is to ensure that coolant is evenly distributed, which helps in dissipating heat generated by the engine. The tube operates by connecting various components of the cooling system, such as the radiator, engine block, and thermostat housing, allowing coolant to circulate and absorb heat from the engine 2.

Purpose of the 3003185 Water Transfer Tube

The Cummins 3003185 Water Transfer Tube is integral to the operation of a truck’s engine cooling system. It facilitates the circulation of coolant, which is vital for maintaining engine temperature. By ensuring a consistent flow of coolant, the tube helps prevent overheating, which can lead to engine damage. Its role in the cooling system is to provide a pathway for coolant to travel from the engine to the radiator and back, ensuring that heat is effectively managed 3.

Key Features

The Cummins 3003185 Water Transfer Tube is constructed from durable materials that are resistant to corrosion and high temperatures. Its design includes precise fittings and connections that ensure a secure and leak-free installation. Unique attributes of this tube may include reinforced sections to withstand pressure fluctuations and a smooth interior to promote efficient coolant flow.

Benefits

The use of the Cummins 3003185 Water Transfer Tube offers several benefits. It contributes to improved engine efficiency by ensuring that the engine operates at optimal temperatures. This can lead to prolonged engine life, as consistent cooling reduces the risk of overheating and related damage. Additionally, the tube’s reliable performance under various operating conditions ensures that the engine cooling system functions effectively in different environments.

Installation Considerations

Proper installation of the Cummins 3003185 Water Transfer Tube is important for its effective function. It is recommended to follow manufacturer guidelines, which may include prerequisites such as ensuring the engine is cool before beginning installation. Tools required may include wrenches for tightening connections and a torque wrench for securing bolts to the specified torque. Steps to ensure a secure and effective fit include verifying that all connections are tight and that there are no obstructions in the coolant flow path.

Troubleshooting Common Issues

Common problems associated with Water Transfer Tubes can include leaks or blockages. To diagnose these issues, one should inspect the tube and connections for signs of coolant leakage or corrosion. If a blockage is suspected, the tube may need to be removed and cleaned or replaced. Regular inspections can help identify potential issues before they lead to more significant problems.

Maintenance Tips

To ensure the long-term reliability and performance of the Cummins 3003185 Water Transfer Tube, regular maintenance is recommended. This includes inspecting the tube and connections for signs of wear or damage at specified intervals. Cleaning procedures may involve flushing the cooling system to remove any buildup that could impede coolant flow. Replacement guidelines should be followed if the tube shows signs of significant wear or if coolant leaks are detected.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive and heavy-duty truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance and reliability of vehicles.

Cummins Water Transfer Tube 3003185 in Engine Applications

The Cummins Water Transfer Tube, part number 3003185, is a critical component in various engine systems. This part is integral to the cooling and thermal management of the engine, ensuring optimal performance and longevity.

V28 Engines

In V28 engines, the Water Transfer Tube 3003185 plays a pivotal role in managing the engine’s thermal dynamics. This engine configuration, typically used in heavy-duty applications, demands precise thermal regulation to maintain efficiency and prevent overheating. The tube facilitates the transfer of coolant between different parts of the engine, ensuring that each cylinder operates within its optimal temperature range.

The V28 engine’s design, with its multiple cylinders, necessitates a robust cooling system. The Water Transfer Tube 3003185 is engineered to withstand the high pressures and temperatures inherent in such an environment. Its placement and design are critical to maintaining the engine’s overall thermal balance, contributing to the engine’s reliability and performance.

Grouping of Engines

For engines grouped by similar thermal management needs, the Water Transfer Tube 3003185 is a common component. These engines, often found in industrial and heavy-duty applications, require efficient coolant distribution to manage the heat generated by their high power output. The tube’s design ensures that coolant flows evenly across the engine, preventing hotspots and ensuring consistent performance.

The integration of the Water Transfer Tube 3003185 in these engines highlights Cummins’ commitment to providing reliable and efficient thermal management solutions. This part’s compatibility across various engine models underscores its versatility and importance in maintaining engine health.

Role of Part 3003185 Water Transfer Tube in Engine Systems

The part 3003185 Water Transfer Tube is an essential component in the efficient operation of various engine systems. It facilitates the movement of water or coolant between different parts of the engine, ensuring optimal performance and temperature regulation.

Integration with Cold Starting Aid

In engines equipped with a Cold Starting Aid system, the Water Transfer Tube plays a significant role. This system is designed to help engines start more easily in cold conditions by warming the intake air. The Water Transfer Tube ensures a consistent flow of heated coolant to the cold starting aid, enhancing its effectiveness. This results in smoother engine starts and reduced wear on engine components during cold starts.

Function in Coolant Inlet Tube System

The Coolant Inlet Tube is responsible for directing coolant into the engine block. The Water Transfer Tube works in tandem with this component, ensuring that the coolant is efficiently transferred from the radiator to the engine. This consistent flow is vital for maintaining the engine’s temperature, preventing overheating, and ensuring that the engine operates within its optimal temperature range.

Contribution to Heater Inlet Tube Operation

In systems where a Heater Inlet Tube is present, the Water Transfer Tube is equally important. The Heater Inlet Tube is part of the engine’s heating system, responsible for directing hot coolant to the heater core. The Water Transfer Tube ensures a steady supply of hot coolant to the heater inlet tube, which is essential for the efficient operation of the vehicle’s heating system. This results in quicker warm-up times for the cabin and consistent heating performance.

Conclusion

The Cummins 3003185 Water Transfer Tube is a key component in various engine systems, facilitating the efficient transfer of coolant and contributing to the overall performance and reliability of the engine. Its role in maintaining optimal engine temperature, ensuring efficient coolant distribution, and integrating with other engine systems underscores its importance in the operation of heavy-duty trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.