This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Water Inlet Connection part #3004799, manufactured by Cummins, is a vital component in the cooling systems of commercial trucks. This part ensures efficient coolant flow from the radiator to the engine block, crucial for maintaining optimal engine temperature and preventing overheating. Understanding its function and significance contributes to better maintenance practices and operational efficiency 1.

Basic Concepts of Water Inlet Connection

A Water Inlet Connection facilitates the entry of coolant into the engine’s cooling system. Its primary role is to direct coolant flow from the radiator to the engine block, where it absorbs heat. This process is essential for maintaining optimal engine temperature, preventing overheating, and ensuring the engine operates within specified temperature ranges 2.

Role of the 3004799 Water Inlet Connection in Truck Operation

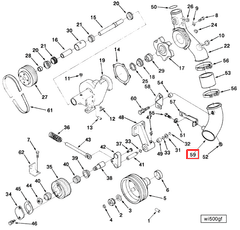

This Cummins part plays a specific role in the operation of a commercial truck by ensuring a consistent and regulated flow of coolant into the engine. It interfaces with the radiator, thermostat, and engine block, working in concert with these components to maintain engine temperature. Proper function of this part is necessary for the overall efficiency and reliability of the truck’s cooling system 3.

Key Features of the 3004799 Water Inlet Connection

The 3004799 is designed with several features that enhance its functionality. It is constructed from durable materials to withstand the high temperatures and pressures within the cooling system. The design includes precise fittings and seals to ensure a leak-free connection, and it may incorporate features such as integrated sensors for monitoring coolant flow and temperature 4.

Benefits of Using the 3004799 Water Inlet Connection

Utilizing this part offers several advantages. Its robust construction contributes to the durability and reliability of the cooling system. The precise design ensures efficient coolant flow, which helps in maintaining optimal engine temperature. Additionally, the integration of advanced features may provide enhanced monitoring capabilities, allowing for proactive maintenance and reduced downtime.

Troubleshooting Common Issues with Water Inlet Connections

Common issues with Water Inlet Connections, including the 3004799 model, may involve leaks, blockages, or sensor malfunctions. Identifying these problems often requires a systematic approach, starting with visual inspections for leaks or damage, followed by checks for proper coolant flow and sensor readings. Resolving these issues may involve repairs or replacements, depending on the severity of the problem.

Maintenance Tips for Water Inlet Connections

Regular maintenance of the Water Inlet Connection is key to ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, ensuring all connections are secure and leak-free, and monitoring coolant levels and condition. Additionally, following the manufacturer’s guidelines for maintenance intervals and procedures can help prevent issues and extend the life of the component.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. Their product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial applications.

Cummins Part 3004799: Water Inlet Connection

The Cummins part 3004799, identified as a Water Inlet Connection, is a critical component in the cooling system of various engines. This part ensures the proper flow of coolant into the engine, which is essential for maintaining optimal operating temperatures and preventing overheating.

V28 Engines

In the V28 engines, the Water Inlet Connection part 3004799 plays a pivotal role in the engine’s cooling system. It is designed to fit seamlessly into the engine’s architecture, ensuring a secure and leak-proof connection. This part is engineered to withstand the high pressures and temperatures typically encountered in these engines, providing durability and reliability over extended periods of use.

The V28 engines, known for their robust performance and efficiency, benefit significantly from the precise fit and function of the Water Inlet Connection. This component is integral to the overall cooling strategy, ensuring that the coolant is delivered efficiently to the engine block, thereby maintaining the engine’s operational integrity.

Role of Part 3004799 Water Inlet Connection in Engine Systems

This part is an integral component in the fluid dynamics of engine systems, ensuring efficient coolant circulation which is vital for maintaining optimal engine temperature. This component interfaces directly with the water inlet, facilitating the entry of coolant into the engine block.

When coolant is introduced into the engine via the water inlet connection, it travels through a network of passages within the engine block and cylinder head. This coolant absorbs heat generated by the combustion process, preventing overheating and ensuring consistent engine performance.

The water inlet mounting connection plays a supportive role by securing the water inlet connection firmly in place. This mounting ensures that the connection remains stable under the pressure and temperature variations typical in engine operation. It also aids in maintaining the integrity of the coolant pathway, preventing leaks that could lead to inefficient cooling and potential engine damage.

Conclusion

In summary, the Water Inlet Connection part #3004799, in conjunction with the water inlet and water inlet mounting connection, forms a reliable coolant delivery system. This system is essential for the sustained operation and longevity of engine components by effectively managing thermal loads.

-

BT Fijalkowski, Automotive Mechatronics Operational and Practical Issues Volume 1, Springer, 2011.

↩ -

Tom Denton and Hayley Pells, Automotive Technician Training, Second Edition, Routledge, 2022.

↩ -

Tom Denton and Hayley Pells, Automotive Technician Training Theory, Routledge, 2022.

↩ -

Thomas D. Gillespie, Fundamentals of Vehicle Dynamics, SAE International, 2021.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.