This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3005829 Fuel Injector Pump is a component designed for use in commercial trucks, specifically engineered to enhance the efficiency and performance of diesel engines. This part is integral to the fuel delivery system, ensuring that the engine receives the precise amount of fuel needed for optimal operation. Its role is significant in maintaining the balance between fuel consumption and engine power, contributing to the overall effectiveness of the vehicle 1.

Basic Concepts of Fuel Injector Pumps

A fuel injector pump is a device that pressurizes diesel fuel and delivers it to the engine’s combustion chamber at the correct time and in the right amount. Within a diesel engine, the pump works in conjunction with the injectors to atomize the fuel, creating a fine mist that mixes with air for combustion. This process is vital for the engine’s operation, as it directly influences the power output and efficiency of the vehicle 2.

Purpose of the Cummins 3005829 Fuel Injector Pump

The Cummins 3005829 Fuel Injector Pump serves a pivotal function in the operation of a truck by ensuring efficient fuel delivery to the engine. It plays a role in maintaining the correct fuel pressure and timing, which are critical for the engine’s performance. By delivering fuel precisely when needed, the pump helps in achieving optimal combustion, which in turn enhances engine power and efficiency 1.

Key Features

The Cummins 3005829 Fuel Injector Pump is characterized by several key features that contribute to its performance and durability. Its design incorporates advanced technology to ensure precise fuel delivery. The pump is constructed from high-quality materials that resist wear and corrosion, ensuring longevity. Additionally, it features a robust build that can withstand the demanding conditions of heavy-duty applications 1.

Benefits

Utilizing the Cummins 3005829 Fuel Injector Pump offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered in the most effective manner possible. This results in better engine performance, as the engine operates more smoothly and with greater power. The pump’s reliability in heavy-duty applications makes it a valuable component for commercial trucks, ensuring consistent performance under various operating conditions 1.

Installation and Integration

Proper installation of the Cummins 3005829 Fuel Injector Pump is crucial for its effective operation. It should be integrated into the truck’s engine system with careful attention to manufacturer guidelines. This includes ensuring that all connections are secure and that the pump is correctly aligned with the engine’s fuel system. Preparations may involve cleaning the installation area and checking for any obstructions that could affect the pump’s performance 2.

Troubleshooting and Maintenance

Regular maintenance and troubleshooting are important for the Cummins 3005829 Fuel Injector Pump to ensure its optimal performance and longevity. Common issues may include fuel delivery problems or pump noise, which can often be addressed through routine checks and adjustments. Maintenance procedures should include regular inspections for wear and tear, cleaning of the pump and its components, and replacement of parts as necessary to prevent failures 2.

Performance and Efficiency

The Cummins 3005829 Fuel Injector Pump plays a significant role in the overall performance and efficiency of a truck’s engine. By ensuring precise fuel delivery, it contributes to better fuel economy and increased power output. This results in a more efficient engine operation, which is crucial for the performance of commercial trucks in various applications 1.

Safety Considerations

When working with the Cummins 3005829 Fuel Injector Pump, it is important to adhere to safety considerations to prevent accidents or injuries. This includes proper handling of the pump and its components, following maintenance procedures as outlined by the manufacturer, and implementing safety protocols when performing repairs or adjustments. Ensuring that all work is done in a safe environment is paramount 2.

Environmental Impact

The Cummins 3005829 Fuel Injector Pump contributes to reducing emissions and promoting cleaner operation in commercial trucks. By ensuring efficient fuel combustion, it helps in minimizing the release of harmful pollutants into the atmosphere. This is an important aspect of its design, reflecting Cummins Inc.’s commitment to environmental responsibility in manufacturing diesel engine components 1.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines, known for its innovation and quality in the industry. With a rich history of producing reliable and efficient engine components, Cummins has established a strong reputation for excellence. The company’s commitment to advancing technology and maintaining high standards in manufacturing is evident in its products, including the Cummins 3005829 Fuel Injector Pump 1.

Compatibility with V28 Engines

The Cummins fuel injector pump part number 3005829 is designed to ensure precise fuel metering and injection timing, which is essential for optimal engine performance and efficiency. Specifically engineered to fit seamlessly into the V28 engine architecture, this part can handle the high demands of the V28 engine, providing the necessary fuel pressure and timing for smooth operation 1.

Role in Engine Systems

The Fuel Injector Pump (part 3005829) is an integral component within the engine system, responsible for delivering precise amounts of fuel to the engine’s combustion chambers. Its operation is synchronized with various other components to ensure optimal engine performance and efficiency 1.

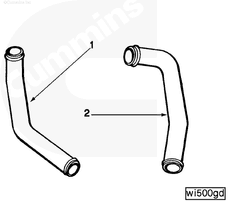

Interaction with Cooling System Components

While the radiator and radiator inlet tube are primarily associated with the engine’s cooling system, the efficient operation of the fuel injector pump is indirectly influenced by the engine’s temperature. The radiator is designed to dissipate heat from the engine coolant, maintaining the engine within its optimal operating temperature range. The radiator inlet tube facilitates the flow of coolant into the radiator, ensuring a continuous cooling process 2.

An overheated engine can lead to decreased fuel efficiency and potential damage to fuel system components, including the fuel injector pump. Therefore, the effective functioning of the radiator and radiator inlet tube contributes to maintaining an environment where the fuel injector pump can operate efficiently 2.

Fuel Delivery and Engine Performance

The fuel injector pump works in conjunction with the fuel injectors, fuel lines, and the engine control unit (ECU) to deliver fuel at the right pressure and timing. This precise fuel delivery is essential for combustion efficiency, power output, and emissions control 1.

Conclusion

In summary, the Cummins 3005829 Fuel Injector Pump plays a significant role in the engine system by ensuring that fuel is delivered efficiently to the combustion chambers. Its operation is supported by the cooling system components, such as the radiator and radiator inlet tube, which help maintain the engine at an optimal temperature for efficient fuel injection and combustion 12.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.