This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

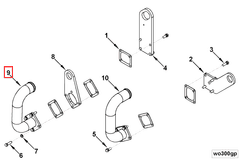

The Water Inlet Connection 3011635, manufactured by Cummins, is a critical component in the engine cooling systems of heavy-duty trucks. Cummins, a renowned name in the automotive and heavy-duty truck industries, produces a range of parts designed to enhance engine performance and reliability. This part is significant in maintaining the optimal operation of engine cooling systems, ensuring efficient heat management and engine longevity 1.

Basic Concepts of Water Inlet Connection

Water inlet connections are fundamental components in engine cooling systems. Their primary function is to facilitate the entry of coolant into the engine block, where it absorbs heat generated during combustion. These connections are strategically placed to ensure uniform coolant distribution throughout the engine. They interact with other cooling system components, such as the thermostat and radiator, to maintain a consistent coolant flow and temperature 2.

Purpose of the 3011635 Water Inlet Connection

This part plays a role in the operation of a truck’s engine cooling system by allowing coolant to enter the engine block efficiently. This component ensures that coolant is distributed evenly, which is vital for dissipating heat away from critical engine components. Proper coolant flow helps in maintaining engine temperature within optimal ranges, thereby enhancing engine performance and longevity 3.

Key Features

The 3011635 Water Inlet Connection is characterized by several key features that contribute to its performance and durability. It is constructed from high-quality materials that resist corrosion and wear, ensuring long-term reliability. The design includes precise fittings and seals that prevent leaks and maintain a consistent coolant flow. Additionally, the connection may feature unique attributes such as reinforced structures or advanced sealing mechanisms to enhance its functionality under demanding conditions 4.

Benefits

The advantages provided by the 3011635 Water Inlet Connection include improved engine efficiency and reliability. By ensuring a consistent and efficient coolant flow, this component helps maintain optimal engine temperatures, which can lead to better fuel efficiency and reduced wear on engine components. Fleet operators may also experience cost savings due to the reduced need for frequent repairs and maintenance associated with a reliable cooling system 5.

Installation Process

Proper installation of the 3011635 Water Inlet Connection is crucial for ensuring optimal performance. The process involves several steps, including gathering necessary tools, preparing the engine compartment, and aligning the connection with the engine block. Detailed instructions should be followed to ensure that the connection is securely fitted and sealed, preventing any coolant leaks and ensuring efficient coolant flow 6.

Troubleshooting Common Issues

Common problems associated with water inlet connections include leaks and blockages. These issues can be diagnosed through visual inspections and pressure tests. Troubleshooting methods may involve tightening connections, replacing worn seals, or cleaning blockages within the coolant passages. Regular inspections and maintenance can help identify and resolve these issues before they lead to more significant problems 7.

Maintenance Tips

To ensure the longevity and efficient operation of the 3011635 Water Inlet Connection, regular maintenance practices are recommended. This includes periodic inspections for signs of wear or damage, cleaning the connection and surrounding areas to prevent debris buildup, and ensuring that all seals and fittings remain intact. Adhering to manufacturer-recommended inspection intervals and maintenance procedures will help maintain the component’s performance over time 8.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive and heavy-duty truck industries. The company’s extensive product range and commitment to customer satisfaction have made it a preferred choice for fleet operators and engine manufacturers worldwide 9.

Role of Part 3011635 Water Inlet Connection in Engine Systems

The Part 3011635 Water Inlet Connection is integral to the efficient operation of several key engine components. It facilitates the smooth flow of coolant into the engine system, ensuring optimal thermal management.

Integration with Torque Converter Oil Cooler

The Water Inlet Connection is directly linked to the Torque Converter Oil Cooler. This cooler is responsible for maintaining the ideal operating temperature of the transmission fluid. The inlet connection ensures a consistent supply of coolant, which is essential for dissipating heat generated during the transmission of torque. This helps in prolonging the lifespan of the transmission system and enhancing its performance 10.

Interaction with Torque Converter Cooler

Similarly, the Water Inlet Connection plays a significant role in the operation of the Torque Converter Cooler. By providing a steady flow of coolant, it aids in the efficient cooling of the torque converter, which is vital for the smooth functioning of the automatic transmission. This connection ensures that the converter operates within its optimal temperature range, thereby reducing the risk of overheating and potential damage 11.

Contribution to Water Outlet and Water Tubes

The Water Inlet Connection also interfaces with the Water Outlet and Water Tubes. It ensures that coolant is effectively distributed throughout the engine block and cylinder head. This consistent coolant flow is essential for maintaining uniform temperatures across different engine components, which is particularly important in high-performance engines where thermal management is a key factor in reliability and efficiency 12.

Conclusion

In summary, the Part 3011635 Water Inlet Connection is a fundamental component in the thermal management system of an engine, ensuring that critical components like the torque converter oil cooler, torque converter cooler, water outlet, and water tubes operate efficiently and reliably.

-

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ -

Mananathan, R. Automobile Wheel Alignment and Wheel Balancing. SAE International, 2022.

↩ -

Naunheimer, Harald, Bernd Bertsche, Joachim Ryborz, and Wolfgang Novak. Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg, 2011.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 6320164.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 6320164.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 6320164.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 6320164.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 6320164.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 6320164.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 6320164.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 6320164.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.