This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

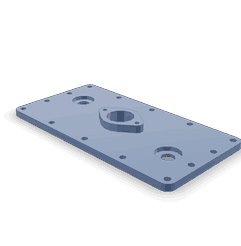

The Water Transfer Connection 3015264, manufactured by Cummins, is a component designed to facilitate the efficient transfer of coolant within the cooling system of commercial trucks. This part is integral to maintaining the optimal operating temperature of the engine, ensuring the longevity and reliability of the vehicle. Cummins, a renowned name in the commercial truck industry, is known for its commitment to quality and innovation in manufacturing truck components 1.

Basic Concepts of Water Transfer Connection

A Water Transfer Connection is a component within the cooling system of a truck that facilitates the movement of coolant from the engine to the radiator and back. This transfer is vital for dissipating heat generated by the engine, thereby maintaining a stable operating temperature. The efficient circulation of coolant helps prevent overheating, which can lead to engine damage 2.

Purpose of the 3015264 Water Transfer Connection

The 3015264 Water Transfer Connection plays a role in the engine cooling process by ensuring the smooth and consistent flow of coolant. It helps maintain optimal engine temperature, which is crucial for the efficient operation of the truck. By facilitating the transfer of coolant, this component contributes to the overall performance and durability of the engine 3.

Key Features

The 3015264 Water Transfer Connection is designed with several features that enhance its performance and durability. It is constructed from high-quality materials that resist corrosion and wear, ensuring a long service life. The design of the connection allows for efficient coolant flow, reducing the risk of blockages and leaks. Additionally, it is engineered to withstand the high pressures and temperatures within the cooling system 4.

Benefits

The use of the 3015264 Water Transfer Connection offers several benefits. It contributes to improved engine efficiency by ensuring consistent coolant flow, which helps maintain optimal engine temperature. This, in turn, enhances the longevity and reliability of the cooling system. The robust design and high-quality materials used in its construction ensure that the component can withstand the demanding conditions of commercial truck operation 1.

Installation Process

Installing the 3015264 Water Transfer Connection requires careful attention to detail to ensure a secure and effective fit. Preparatory steps include cleaning the installation area and ensuring that all old gaskets and sealants are removed. The necessary tools for installation include a torque wrench and appropriate sealants. Following the manufacturer’s instructions, the connection should be aligned with the coolant passages and secured in place. It is important to check for proper alignment and sealing to prevent leaks 2.

Troubleshooting Common Issues

Common issues associated with Water Transfer Connections include leaks and blockages. Leaks can often be identified by coolant loss or visible drips near the connection. Blockages may result in reduced coolant flow, indicated by overheating or inconsistent engine temperature. Troubleshooting steps include inspecting the connection for signs of wear or damage, ensuring proper alignment and sealing, and checking for any obstructions within the coolant passages 3.

Maintenance Tips

Regular maintenance of the 3015264 Water Transfer Connection is important for ensuring continued optimal performance. Inspection intervals should be in accordance with the manufacturer’s recommendations, typically during routine coolant system checks. Cleaning the connection and surrounding areas can help prevent buildup that may lead to blockages. If signs of wear or damage are detected, consideration should be given to replacement to maintain the efficiency of the cooling system 4.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle operators. Cummins’ commitment to quality is evident in its rigorous testing and quality control processes, ensuring that its components, like the 3015264 Water Transfer Connection, deliver reliable performance and durability 1.

Role of Part 3015264 Water Transfer Connection in Engine Systems

The 3015264 water transfer connection is integral to the efficient operation of various engine systems. It facilitates the seamless transfer of water between the engine’s cooling system and other components, ensuring optimal thermal management 2.

Cooling System Integration

In the cooling system, the water transfer connection plays a significant role by linking the water pump to the engine block and radiator. This ensures a consistent flow of coolant, which absorbs heat from the engine components and transfers it to the radiator for dissipation. The reliable connection provided by part 3015264 helps maintain the engine’s operating temperature within safe limits, preventing overheating and potential damage 3.

Performance Parts Compatibility

When integrating performance parts, such as high-flow water pumps or upgraded radiators, the water transfer connection ensures compatibility and efficient coolant circulation. This is particularly important in high-performance engines where increased heat generation necessitates enhanced cooling capabilities. The part 3015264 allows for a secure and leak-free connection, supporting the performance gains achieved through these upgrades 4.

Engine Block and Head Connection

The water transfer connection also interfaces with the engine block and cylinder head, facilitating the circulation of coolant through the water jackets. This helps in evenly distributing heat across the engine, reducing thermal stress on critical components like pistons, cylinders, and bearings. The part 3015264 ensures that these connections remain intact under varying engine loads and temperatures, contributing to the engine’s longevity and reliability 1.

Thermostat Housing Link

Additionally, the water transfer connection is often part of the thermostat housing assembly. It ensures that coolant flow is regulated according to the engine’s temperature, allowing the thermostat to open and close as needed. This regulation is vital for achieving the engine’s optimal operating temperature quickly and maintaining it during operation, which is essential for efficient combustion and reduced emissions 2.

Auxiliary Cooling Systems

In engines equipped with auxiliary cooling systems, such as oil coolers or intercoolers, the water transfer connection plays a role in integrating these systems into the main cooling loop. This ensures that all components benefit from the coolant’s heat-absorbing properties, enhancing the overall efficiency and performance of the engine 3.

Conclusion

Understanding the role of the 3015264 Water Transfer Connection in various engine systems highlights its importance in maintaining engine health and performance. Its design and features ensure efficient coolant circulation, compatibility with performance parts, and integration with auxiliary cooling systems, all of which contribute to the overall reliability and longevity of the engine 4.

-

MJ Nunney, Light and Heavy Vehicle Technology, Fourth Edition, Butterworth-Heinemann, 2007.

↩ ↩ ↩ ↩ -

Douglas R. Fehan, Design of Racing and High-Performance Engines 2004-2013, SAE International, 2013.

↩ ↩ ↩ ↩ -

Haoran Hu, Simon J Baseley and Xubin Song, Advanced Hybrid Powertrains for Commercial Vehicles Second Edition, SAE International, 2021.

↩ ↩ ↩ ↩ -

Rolf Isermann, Combustion Engine Diagnosis, Springer Vieweg, 2017.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.