3171784

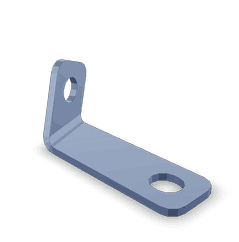

Water Tube Bracket

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Water Tube Bracket 3171784, manufactured by Cummins, is a component designed for use in heavy-duty truck engines. Cummins, a well-established name in the automotive industry, is known for producing reliable and high-performance engine parts. This part is significant in the context of heavy-duty truck engines due to its role in supporting and securing critical components within the engine’s cooling system 1.

Purpose and Function

The Water Tube Bracket 3171784 plays a role in the operation of a truck engine by providing a mounting point for the water tube within the engine’s cooling system. It is strategically placed to ensure the water tube is correctly positioned and securely held in place. This bracket interacts with other components such as the water tube, engine block, and potentially other cooling system parts, facilitating the efficient circulation of coolant throughout the engine 2.

Key Features

The Water Tube Bracket 3171784 is designed with specific characteristics to enhance its performance and durability. It is typically made from high-strength materials to withstand the demanding conditions within a heavy-duty engine. The design of the bracket may include features such as precise mounting points, corrosion-resistant coatings, and a robust construction to ensure it can endure high temperatures and pressures. These attributes contribute to the overall reliability and longevity of the component 3.

Benefits

The use of the Water Tube Bracket 3171784 offers several advantages. It contributes to improved engine efficiency by ensuring the water tube is correctly positioned, which aids in the effective circulation of coolant. This, in turn, helps maintain optimal engine temperatures, enhancing overall engine performance. Additionally, the durable construction of the bracket supports the reliability of the cooling system, reducing the likelihood of failures. Furthermore, its design may facilitate easier maintenance and replacement, minimizing downtime for heavy-duty trucks 4.

Installation Process

Proper installation of the Water Tube Bracket 3171784 involves several steps to ensure it is correctly positioned and securely fastened. The process may require specific tools, such as torque wrenches, to ensure bolts are tightened to the manufacturer’s specifications. It is important to follow the manufacturer’s guidelines for installation, which may include cleaning the mounting surface, applying any necessary sealants, and verifying the alignment of the bracket with the water tube and other components 5.

Maintenance Tips

Regular inspection and maintenance of the Water Tube Bracket 3171784 are recommended to ensure optimal performance and longevity. This may involve checking for signs of wear or damage, ensuring all fasteners are tight, and verifying the alignment of the bracket with the water tube. Additionally, keeping the area around the bracket clean and free of debris can help prevent issues related to corrosion or obstruction of the cooling system 6.

Troubleshooting Common Issues

Typical problems associated with the Water Tube Bracket 3171784 may include loosening of fasteners, corrosion, or physical damage to the bracket. Suggested solutions or corrective actions may involve re-tightening fasteners to the correct torque specifications, applying corrosion-resistant coatings, or replacing the bracket if it is damaged. Regular maintenance checks can help identify and address these issues before they lead to more significant problems 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive industry. The company offers a wide range of products, including diesel and natural gas engines, as well as related technologies and services, catering to various industries and applications 8.

Water Tube Bracket Part 3171784 Compatibility with Cummins Engines

The Water Tube Bracket part 3171784 is a critical component in the engine systems of various Cummins engines. This part is designed to securely hold and position water tubes, ensuring efficient heat transfer and maintaining optimal engine performance.

QSK60 CM500 and QSK60 CM850 MCRS

The Water Tube Bracket part 3171784 is compatible with the QSK60 CM500 and QSK60 CM850 MCRS engines. These engines are known for their robust design and high performance, often used in heavy-duty applications such as marine and industrial settings. The bracket’s precise fit and durability ensure that the water tubes remain in place, facilitating effective cooling and preventing overheating.

QSK60G

Similarly, the QSK60G engine also utilizes the Water Tube Bracket part 3171784. This engine is part of Cummins’ QSK60 series, which is designed for high-power applications. The bracket’s role in this engine is to maintain the integrity of the water tubes, ensuring that the engine operates within safe temperature limits. The bracket’s design allows for easy installation and maintenance, contributing to the engine’s overall reliability and longevity.

In summary, the Water Tube Bracket part 3171784 is a vital component for the QSK60 CM500, QSK60 CM850 MCRS, and QSK60G engines, ensuring the proper functioning of the cooling system and maintaining engine performance 9.

Role of Part 3171784 Water Tube Bracket in Engine Systems

The Water Tube Bracket 3171784 is integral to the efficient operation and integration of various engine components. It serves as a mounting point for the water tubes, ensuring secure and stable connections within the engine system.

In the context of the harness and electronic control module (ECM) wiring, the Water Tube Bracket facilitates the organized routing of wires and tubes, minimizing the risk of interference or damage. This is particularly important for maintaining the integrity of the engine control module signals and ensuring reliable communication between the ECM and other engine components.

For the plumbing systems involving aftercooler water and intercooler water, the bracket ensures that the water tubes are correctly positioned and supported. This is essential for maintaining the optimal flow of cooling water, which is vital for the efficient operation of the turbocharger. Proper water flow helps in managing the temperature of the compressed air, thereby enhancing turbocharger performance and longevity.

In terms of turbocharger oil plumbing, the Water Tube Bracket plays a role in keeping the oil lines secure and well-organized. This is important for maintaining the lubrication system of the turbocharger, which is necessary for its smooth operation and durability.

Additionally, the bracket supports the positioning of sensors, such as those measuring exhaust gas temperature (EGT). Accurate sensor readings are dependent on their precise placement, which the bracket helps to achieve. This ensures that the ECM receives correct data for optimal engine management.

Overall, the Water Tube Bracket 3171784 is a key component in maintaining the structural integrity and functional efficiency of various engine systems, ensuring that all interconnected parts operate harmoniously 10.

Conclusion

The Water Tube Bracket 3171784 is a critical component in the cooling systems of heavy-duty truck engines, particularly those manufactured by Cummins. Its role in securing and positioning water tubes ensures efficient coolant circulation, which is vital for maintaining optimal engine temperatures and performance. The bracket’s durable construction and precise design contribute to the reliability and longevity of the cooling system. Regular maintenance and proper installation are essential to maximize the benefits of this part, ensuring the engine operates efficiently and reliably.

-

Automotive Technician Training Theory, Tom Denton and Hayley Pells, Routledge, 2022.

↩ -

Fundamentals of Integrated Vehicle Realization, Mohamed ElSayed PE, SAE International, 2017.

↩ -

The History and Impact of Diesel Engines and Gas Turbines, Vaclav Smil, The MIT Press, 2010.

↩ -

Engine: ISB6.7 CM2350 B142 Stop-Start Applications, Bulletin Number: 5411133, Owners Manual.

↩ -

Automotive Technician Training Theory, Tom Denton and Hayley Pells, Routledge, 2022.

↩ -

Fundamentals of Integrated Vehicle Realization, Mohamed ElSayed PE, SAE International, 2017.

↩ -

The History and Impact of Diesel Engines and Gas Turbines, Vaclav Smil, The MIT Press, 2010.

↩ -

Engine: ISB6.7 CM2350 B142 Stop-Start Applications, Bulletin Number: 5411133, Owners Manual.

↩ -

Automotive Technician Training Theory, Tom Denton and Hayley Pells, Routledge, 2022.

↩ -

Fundamentals of Integrated Vehicle Realization, Mohamed ElSayed PE, SAE International, 2017.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.