3635395

Water Transfer Connection Gasket

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3635395 Water Transfer Connection Gasket is a component designed for use in commercial trucks. It serves a specific function within the engine cooling system, ensuring the efficient transfer of coolant and maintaining the integrity of the system.

Basic Concepts of Water Transfer Connection Gaskets

A water transfer connection gasket is a sealing component used in engine cooling systems. Its primary function is to create a secure seal between various components, such as the water pump and engine block, allowing for the smooth transfer of coolant. This seal is vital for preventing coolant leaks, which could lead to engine overheating and potential damage 1.

Purpose of the 3635395 Water Transfer Connection Gasket

This Cummins part plays a role in the truck’s engine cooling system by sealing the connection points where coolant is transferred. This ensures that coolant flows efficiently through the system without leakage, which is important for maintaining optimal engine temperature and performance.

Key Features

The 3635395 gasket is characterized by its material composition, which is designed to withstand the high temperatures and pressures within an engine cooling system. Its design specifications ensure a precise fit, enhancing its sealing capabilities. Additionally, it may feature unique attributes such as reinforced edges or specialized coatings to improve durability and performance.

Benefits

Using the 3635395 gasket offers several advantages. It contributes to improved engine efficiency by ensuring a consistent flow of coolant. Reduced maintenance needs are another benefit, as a well-sealed system is less prone to leaks and failures. Furthermore, the enhanced reliability of the cooling system leads to better overall engine performance and longevity.

Installation Process

Proper installation of the 3635395 gasket involves several steps to ensure optimal performance. Preparation includes cleaning the mating surfaces to remove any debris or old gasket material. The gasket should then be fitted carefully into place, ensuring it aligns correctly with the connection points. Securing procedures may involve the use of clamps or other fastening methods to hold the gasket in place 2.

Common Issues and Troubleshooting

Typical problems associated with water transfer connection gaskets include leaks or failures, which can arise from improper installation, wear and tear, or material degradation. Troubleshooting these issues may involve inspecting the gasket for signs of damage, checking the fit and alignment, and ensuring that all connection points are secure. Replacement of the gasket may be necessary in cases of significant wear or damage.

Maintenance Tips

To prolong the lifespan of the 3635395 gasket, regular maintenance practices are recommended. This includes periodic inspection for signs of wear or damage, cleaning the gasket and mating surfaces to prevent buildup, and following manufacturer guidelines for replacement intervals. Adhering to these practices helps maintain the integrity of the engine cooling system.

Manufacturer Information - Cummins

Cummins Inc. is a well-established company in the automotive industry, known for its high-quality engine components. With a history of innovation and commitment to excellence, Cummins has built a reputation for producing reliable and durable parts. The company’s dedication to quality is evident in its range of engine components, including the 3635395 Water Transfer Connection Gasket.

Application in Cummins Engines

The part 3635395 is compatible with a range of Cummins engines, including:

-

QSK38 Series:

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

-

QSK50 Series:

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

-

QSK60 Series:

- QSK60 CM500

- QSK60 CM850 MCRS

-

QSK95 Series:

- QSK95 CM2350 K111

- QSK95 CM2350 K113

Importance of the Gasket

The Water Transfer Connection Gasket is crucial for the following reasons:

- Prevents Leaks: Ensures that water does not leak from the transfer connections, which could lead to overheating and engine damage.

- Maintains Pressure: Helps maintain the necessary pressure within the cooling system, ensuring efficient heat transfer.

- Durability: Made from high-quality materials, the gasket can withstand the high temperatures and pressures within the engine’s cooling system.

Installation Considerations

When installing the Cummins Water Transfer Connection Gasket, it is important to:

- Ensure the mating surfaces are clean and free of debris.

- Follow the manufacturer’s guidelines for torque specifications to avoid over-tightening or under-tightening.

- Use the correct gasket material compatible with the engine’s cooling system fluids.

Role of Part 3635395 Water Transfer Connection Gasket in Engine Systems

The Water Transfer Connection Gasket, part number 3635395, is an essential component in ensuring the integrity and efficiency of various engine systems. This gasket is specifically designed to create a secure seal between the water transfer tube and other critical components within the engine’s cooling system.

Integration with Cooling System Components

- Water Pump Kit: The gasket ensures a leak-free connection between the water transfer tube and the water pump. This is vital for maintaining consistent coolant flow, which is necessary for effective heat dissipation from the engine.

- Thermostat Housing: When installed between the water transfer tube and the thermostat housing, the gasket prevents coolant leaks. This maintains the proper operating temperature of the engine by ensuring the thermostat functions correctly within a sealed environment.

- Manifold and Pan: The gasket also plays a role in sealing connections to the manifold and pan, ensuring that coolant circulates efficiently without any loss, which could lead to overheating or inefficient cooling.

Role in Auxiliary Cooling Systems

- Auxiliary Cooling System: In engines equipped with an auxiliary cooling system, the gasket ensures that the connection between the water transfer tube and the auxiliary cooling components remains sealed. This is important for maintaining the additional cooling capacity required during high-stress operations.

- Water Bypass Tube: The gasket is used to seal the connection between the water transfer tube and the water bypass tube. This ensures that coolant can effectively bypass certain areas of the engine when necessary, contributing to balanced cooling across all engine components.

Sealing in Cooling System Gasket Sets

- Cooling System Gasket Kit and Set: Part 3635395 is often included in cooling system gasket kits and sets. Its role is to provide a comprehensive seal across multiple connection points within the cooling system, ensuring that the entire system operates as a unified, leak-free unit.

Interaction with Breather and Crankcase

- Breather and Crankcase: Although the primary function of the gasket is within the cooling system, its effective sealing capabilities indirectly support the breather and crankcase functions. By maintaining a sealed cooling system, it helps in preventing any coolant-related issues that could affect the breather and crankcase operations.

Single Head Gasket Kit and Set

- Single Head Gasket Kit and Set: While the Water Transfer Connection Gasket is not a head gasket, its proper installation and function are complementary to the head gasket’s role. A well-sealed cooling system ensures that the head gasket operates in an environment free from coolant contamination, which could otherwise lead to gasket failure.

Conclusion

The Water Transfer Connection Gasket (part 3635395) is a fundamental component in maintaining the efficiency and reliability of the engine’s cooling system. Its role in sealing various connections ensures that coolant flows smoothly and effectively, supporting the overall performance and longevity of the engine.

SPECIFICATIONS

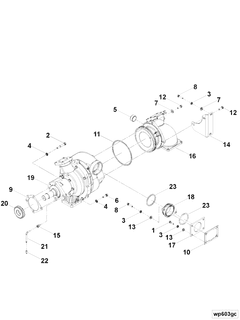

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.