This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

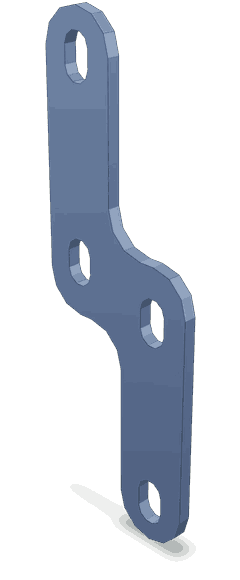

The Water Tube Bracket, part number 3650259, manufactured by Cummins, is a critical component designed for use in commercial trucks. Cummins, a renowned name in the automotive industry, is known for producing reliable and high-performance parts and engines. This part is integral to the engine cooling system, ensuring efficient operation under various conditions.

Function and Operation

The Water Tube Bracket plays a role in the engine cooling system by securing the water tube, which circulates coolant throughout the engine. This circulation is essential for dissipating heat generated during engine operation. The bracket ensures that the water tube remains correctly positioned and aligned, facilitating optimal coolant flow. It interacts with other cooling system components, such as the radiator, thermostat, and water pump, to maintain consistent engine temperature 1.

Key Features

This Cummins part is constructed from durable materials, designed to withstand the high temperatures and pressures within the engine cooling system. Its design includes specific mounting points that allow for secure attachment to the engine block. The bracket is engineered to provide stability and support to the water tube, enhancing the overall efficiency of the cooling system. Additionally, its design considers factors such as thermal expansion and contraction, ensuring long-term performance and reliability 2.

Benefits

The use of the Water Tube Bracket offers several advantages. It contributes to improved coolant flow, which is vital for maintaining optimal engine temperature. Enhanced coolant circulation leads to more efficient engine cooling, reducing the risk of overheating and potential engine damage. Furthermore, by ensuring stable and secure placement of the water tube, the bracket plays a part in the overall performance and longevity of the engine 3.

Installation and Maintenance

Proper installation of the Water Tube Bracket is crucial for its effective function. It should be securely fastened to the designated mounting points on the engine block, ensuring that the water tube is correctly aligned. Regular maintenance checks are recommended to verify the bracket’s condition and ensure it remains securely attached. Any signs of wear or damage should be addressed promptly to prevent potential cooling system failures.

Troubleshooting

Common issues associated with the Water Tube Bracket may include loosening of the mounting points, damage to the bracket itself, or misalignment of the water tube. Diagnostic steps involve inspecting the bracket and its attachment points for any signs of wear, corrosion, or damage. If issues are identified, the recommended course of action may involve tightening or replacing the bracket, or adjusting the water tube’s position to ensure proper alignment and function.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable, high-performance engines and components. The company’s commitment to innovation, quality, and customer satisfaction has made it a preferred choice among commercial vehicle manufacturers and operators worldwide.

Role of the Water Tube Bracket in Engine Systems

The Water Tube Bracket is an essential component that facilitates the secure mounting and alignment of various water tubes within the engine’s cooling system. This bracket ensures that the tubes remain in the correct position, allowing for efficient coolant flow and optimal engine performance.

Integration with Auxiliary Cooling System

In the auxiliary cooling system, the Water Tube Bracket supports the water bypass tube and water transfer tube. These tubes are responsible for redirecting coolant flow to maintain consistent engine temperatures, especially under high-load conditions. The bracket ensures that these tubes are held firmly in place, preventing any misalignment that could lead to coolant leaks or inefficient cooling.

Interaction with Manifold and Water System

When integrated with the manifold and the primary water system, the Water Tube Bracket helps maintain the structural integrity of the coolant pathways. It supports the tubes that connect the manifold to the water system, ensuring that coolant is distributed evenly across the engine components. This consistent distribution is vital for preventing hotspots and ensuring that all parts of the engine receive adequate cooling.

Supporting Auxiliary Cooling Components

In systems that employ an auxiliary cooling system, the bracket is instrumental in supporting additional water tubes that enhance the engine’s cooling capabilities. These systems are often used in high-performance engines or those operating in extreme conditions, where standard cooling may be insufficient. The Water Tube Bracket ensures that these auxiliary components are securely mounted, allowing them to function effectively without the risk of detachment or failure.

Ensuring System Reliability

By providing a stable mounting point for the water tubes, the Water Tube Bracket contributes to the overall reliability of the engine’s cooling system. It allows for easier maintenance and replacement of tubes, as the bracket can be quickly accessed without disrupting other components. This feature is particularly beneficial in environments where rapid turnaround times are essential.

Conclusion

The Water Tube Bracket, part number 3650259, is a key component in maintaining the efficiency and reliability of the engine’s cooling system. Its role in securing and aligning water tubes ensures optimal coolant flow and engine performance. Proper installation, regular maintenance, and prompt troubleshooting are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.