This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

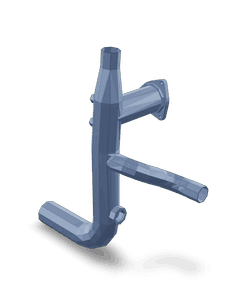

The Cummins 3651277 Water Transfer Tube is a component designed for use in heavy-duty trucks. Its purpose is to facilitate the efficient transfer of coolant within the engine’s cooling system. This part is significant in maintaining the operational integrity of the truck by ensuring that the engine operates within optimal temperature ranges 1.

Basic Concepts of Water Transfer Tubes

A Water Transfer Tube is a conduit within the cooling system that allows coolant to move from one part of the engine to another. Its function is to ensure that coolant circulates effectively, which helps in dissipating heat generated by the engine. By maintaining optimal engine temperature, the Water Transfer Tube contributes to the longevity and efficiency of the engine 2.

Purpose of the Cummins 3651277 Water Transfer Tube

The Cummins 3651277 Water Transfer Tube plays a role in the operation of a truck by participating in the coolant circulation process. It ensures that coolant is evenly distributed throughout the engine, which aids in regulating engine temperature. This regulation is vital for preventing overheating and ensuring that the engine operates within its designed parameters 3.

Key Features

The Cummins 3651277 Water Transfer Tube is constructed with materials that are resistant to corrosion and high temperatures, ensuring durability and longevity. It features secure connection types that prevent leaks and maintain the integrity of the cooling system. Unique attributes of this tube may include reinforced sections to withstand pressure fluctuations and a design that optimizes coolant flow.

Benefits

The advantages provided by the Cummins 3651277 Water Transfer Tube include improved coolant flow, which enhances the engine’s cooling efficiency. This results in better engine protection against overheating and reduces the risk of engine damage. Additionally, the tube’s robust construction increases its reliability, especially under demanding operating conditions typical of heavy-duty trucks.

Installation and Compatibility

Proper installation of the Cummins 3651277 Water Transfer Tube involves following manufacturer guidelines to ensure it is securely fitted within the cooling system. It is important to use the correct tools and techniques to prevent damage to the tube or the surrounding components. Information on compatible truck models and engine types should be consulted to ensure the tube is suitable for the specific application.

Maintenance and Troubleshooting

Routine maintenance practices for the Cummins 3651277 Water Transfer Tube include regular inspections for signs of wear, corrosion, or leaks. It is also important to ensure that all connections are tight and that the coolant level is adequate. Common issues that may arise include leaks or blockages, which can be diagnosed through visual inspection and pressure testing. Recommended solutions may involve repairing or replacing the tube if necessary.

Performance and Efficiency

The Cummins 3651277 Water Transfer Tube contributes to the overall performance and efficiency of the truck’s cooling system by ensuring that coolant is effectively circulated. This can have a positive impact on fuel economy, as an engine that operates within its optimal temperature range tends to be more efficient. Additionally, proper cooling system function can extend engine longevity by preventing overheating-related damage.

Cummins Corporation

Cummins Inc. is a well-established manufacturer in the automotive and heavy-duty truck industry, known for its wide range of products and commitment to quality and innovation. The company has a history of producing reliable and high-performance components, and the Cummins 3651277 Water Transfer Tube is a testament to this reputation. Cummins’ focus on quality manufacturing ensures that their components meet the rigorous demands of heavy-duty applications.

Compatibility with Cummins Engines

The Water Transfer Tube, identified by part number 3651277, is a critical component in the cooling systems of various Cummins engines. This part is designed to facilitate the transfer of coolant between different parts of the engine, ensuring efficient thermal management and preventing overheating.

QSK60 and CM850 Engines

The QSK60 and CM850 engines, both part of Cummins’ heavy-duty diesel engine lineup, are engineered for demanding applications such as marine and stationary power. The Water Transfer Tube in these engines is integral to maintaining optimal operating temperatures by ensuring that coolant is evenly distributed throughout the engine’s cooling system. This part’s design and placement are critical to the overall efficiency and longevity of the engine.

MCRS Engines

The MCRS engines, which are also part of Cummins’ robust engine family, benefit from the Water Transfer Tube in similar ways. These engines are typically used in military and defense applications, where reliability and performance under extreme conditions are paramount. The Water Transfer Tube ensures that the MCRS engines can handle high thermal loads and maintain consistent performance, even in the most challenging environments.

Grouping Considerations

When considering the compatibility of the Water Transfer Tube with Cummins engines, it is essential to recognize that the QSK60 and CM850 engines share many design and engineering principles, making them suitable candidates for this part. The MCRS engines, while distinct in their specific applications, also benefit from the same thermal management strategies that the Water Transfer Tube supports. Therefore, the part number 3651277 is applicable across these engine groups, ensuring a standardized approach to cooling system maintenance and performance.

Role of Part 3651277 Water Transfer Tube in Engine Systems

The 3651277 Water Transfer Tube is an integral component in the efficient operation of engine systems, particularly in the context of cooling and water management. This component facilitates the smooth transfer of water between various engine parts, ensuring optimal performance and longevity of the engine.

Integration with Key Components

Connection to Engine Components

The Water Transfer Tube establishes a vital connection between the engine’s water pump and the water outlet. This connection ensures a consistent flow of coolant, which is essential for maintaining the engine’s temperature within safe operating limits. The tube’s design allows for minimal resistance, enhancing the efficiency of coolant circulation.

Interaction with the Water Outlet

At the water outlet, the 3651277 Water Transfer Tube plays a significant role in directing the coolant flow to the radiator. This process is essential for dissipating heat absorbed by the coolant as it circulates through the engine. The tube’s precise fit and secure connection at the water outlet prevent leaks and ensure that the coolant is effectively transferred to the radiator for cooling.

Enhancing Engine Performance

By ensuring a reliable and efficient transfer of coolant, the 3651277 Water Transfer Tube contributes to the overall performance and reliability of the engine. Its role in maintaining a consistent coolant flow helps prevent overheating, which can lead to engine damage and reduced efficiency. Additionally, the tube’s durable construction ensures it can withstand the pressures and temperatures associated with engine operation, providing long-term reliability.

Conclusion

The Cummins 3651277 Water Transfer Tube is a vital component in the cooling systems of heavy-duty trucks, ensuring efficient coolant circulation and engine temperature regulation. Its robust construction, compatibility with various Cummins engines, and role in enhancing engine performance and reliability make it an essential part for maintaining the operational integrity of heavy-duty applications.

-

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩ -

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Minaker, B. P. (2019). Fundamentals of Vehicle Dynamics and Modelling. John Wiley Sons.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.