This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

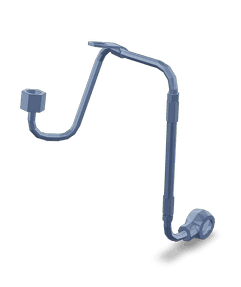

The Cummins 3697323 Water Inlet Tube is a critical component in the cooling systems of heavy-duty trucks. It ensures the efficient flow of coolant into the engine, maintaining optimal engine temperature under various driving conditions. This part is essential for the proper functioning of the cooling system, contributing to the engine’s operational efficiency and longevity 1.

Basic Concepts of Water Inlet Tubes

A water inlet tube serves as a conduit for directing coolant from the radiator into the engine block. Its primary function is to ensure a steady and consistent flow of coolant, which absorbs heat from engine components and dissipates it through the radiator. This stable coolant flow is vital for preserving the engine’s efficiency and longevity 2.

Purpose of the Cummins 3697323 Water Inlet Tube

The Cummins 3697323 Water Inlet Tube is designed to direct coolant flow into the engine, ensuring effective circulation through the engine block. This part absorbs heat from critical components, maintaining optimal engine temperature. Its design is tailored to handle the demands of heavy-duty applications, providing reliable coolant distribution under strenuous conditions 3.

Key Features

The Cummins 3697323 Water Inlet Tube is constructed from durable materials to withstand high pressures and temperatures in heavy-duty truck engines. It features precise fittings and connections for a secure and leak-free installation. Reinforced sections enhance its durability and resistance to wear and tear 4.

Benefits of Using the Cummins 3697323 Water Inlet Tube

Utilizing this Cummins part promotes improved coolant flow, which is vital for effective engine cooling. It enhances engine protection by maintaining optimal operating temperatures. The tube’s robust construction and design contribute to increased reliability, ensuring consistent performance in demanding conditions 5.

Installation and Compatibility

Proper installation of the Cummins 3697323 Water Inlet Tube involves following manufacturer guidelines for a secure and efficient fit. This may require specific tools or equipment to achieve the correct torque settings and connections. Compatibility with various truck models and engine types should be verified to ensure optimal performance and integration within the cooling system 6.

Maintenance and Troubleshooting

Routine maintenance of the Cummins 3697323 Water Inlet Tube includes regular inspections for signs of wear, corrosion, or leaks. Cleaning the tube and its connections can prevent buildup that may impede coolant flow. Troubleshooting common issues such as leaks or blockages involves checking connections, inspecting for damage, and ensuring the tube is properly seated and secured 7.

Common Issues and Solutions

Common problems associated with water inlet tubes include leaks, blockages, and corrosion. For the Cummins 3697323, addressing these issues may involve tightening connections, cleaning or replacing the tube, and applying corrosion-resistant coatings. Preventive measures include regular maintenance checks and using high-quality coolant to reduce the risk of corrosion and buildup 8.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a long-standing reputation in the automotive and heavy-duty truck industries. The company is committed to producing high-quality components that meet the rigorous demands of commercial and industrial applications. Cummins’ dedication to innovation and excellence is reflected in its wide range of reliable and efficient automotive parts 9.

Role of the Cummins 3697323 Water Inlet Tube in Engine Systems

The Cummins 3697323 Water Inlet Tube is an essential component in the efficient operation of various engine systems, particularly in scenarios where water injection is utilized to enhance performance and efficiency.

Integration with Plumbing Systems

In engine systems equipped with water injection, the Water Inlet Tube is responsible for directing water into the combustion chamber. This process is meticulously integrated with the engine’s plumbing system. The tube connects to the water reservoir, ensuring a steady and controlled flow of water. The plumbing system, which includes hoses, fittings, and regulators, works in tandem with the Water Inlet Tube to maintain the desired water pressure and flow rate. This integration is vital for optimizing the water injection process, which helps in reducing knocking, improving fuel efficiency, and enhancing overall engine performance 10.

Interaction with Turbochargers

When paired with a turbocharger, the Water Inlet Tube plays a significant role in managing the increased stress and heat generated by forced induction. Turbochargers compress air before it enters the combustion chamber, which can lead to higher temperatures and potential engine damage. The Water Inlet Tube facilitates the injection of water into the intake air stream, which helps in cooling the air charge. This cooling effect reduces the likelihood of detonation and allows for higher boost levels without compromising engine integrity. The interaction between the Water Inlet Tube and the turbocharger is designed to balance performance gains with the need for reliable and sustained operation 11.

Conclusion

The Cummins 3697323 Water Inlet Tube is a key component in enhancing the functionality and efficiency of engine systems. Its role in facilitating water injection contributes significantly to the overall performance and durability of the engine. Regular maintenance and proper installation are essential to ensure the optimal operation of this critical part.

-

Automotive Principles: Diagnosis and Service, James D. Halderman, Prentice Hall, 2012.

↩ -

Fundamentals of Medium-Heavy Duty Diesel Engines, Gus Wright, Jones & Bartlett Learning, 2015.

↩ -

An Introduction to Modern Vehicle Design, Julian Happian-Smith, Butterworth-Heinemann, 2002.

↩ -

Automotive Braking Systems, Nicholas Goodnight and Kirk Van Gelder, Jones & Bartlett Learning, 2018.

↩ -

Engine: QSB6.7 CM2350 B112, Bulletin Number: 4358501, Fault Code Troubleshooting Manual.

↩ -

Automotive Principles: Diagnosis and Service, James D. Halderman, Prentice Hall, 2012.

↩ -

Fundamentals of Medium-Heavy Duty Diesel Engines, Gus Wright, Jones & Bartlett Learning, 2015.

↩ -

An Introduction to Modern Vehicle Design, Julian Happian-Smith, Butterworth-Heinemann, 2002.

↩ -

Automotive Braking Systems, Nicholas Goodnight and Kirk Van Gelder, Jones & Bartlett Learning, 2018.

↩ -

Engine: QSB6.7 CM2350 B112, Bulletin Number: 4358501, Fault Code Troubleshooting Manual.

↩ -

Fundamentals of Medium-Heavy Duty Diesel Engines, Gus Wright, Jones & Bartlett Learning, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.