This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

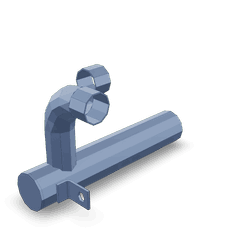

The Cummins 3897918 Water Transfer Tube is a component designed to facilitate the efficient transfer of coolant within the cooling system of heavy-duty trucks. Its purpose is to ensure that the engine maintains optimal operating temperatures by circulating coolant between the engine block and the radiator. This component plays a role in the cooling system by enhancing the overall thermal management of the engine, which is vital for maintaining performance and longevity 3.

Function and Operation

The Water Transfer Tube operates by directing coolant flow from the engine block to the radiator and back. It interacts with several key components within the cooling system, including the radiator, engine block, and thermostat. As the engine generates heat, the coolant absorbs this thermal energy and is pumped through the Water Transfer Tube to the radiator. Here, the heat is dissipated into the ambient air, allowing the coolant to return to the engine at a lower temperature. This continuous cycle helps to regulate engine temperature and prevent overheating 1.

Key Features

The Cummins 3897918 Water Transfer Tube is constructed from durable materials that are resistant to corrosion and high temperatures. Its design includes precise fittings and connections that ensure a secure and leak-free installation. The tube’s robust construction contributes to its longevity and reliability in demanding operating conditions. Additionally, the Water Transfer Tube may feature unique attributes such as reinforced sections to withstand pressure fluctuations and enhanced flow pathways to optimize coolant circulation 2.

Benefits

The advantages provided by the Cummins 3897918 Water Transfer Tube include improved cooling efficiency, which helps to maintain stable engine temperatures under various operating conditions. This can lead to reduced risk of overheating, which is particularly important in heavy-duty applications where engines are subjected to high loads and extended operation. Furthermore, the enhanced cooling performance contributes to overall engine efficiency and can potentially extend the lifespan of the engine by minimizing thermal stress 3.

Installation and Compatibility

Proper installation of the Water Transfer Tube involves several steps to ensure it functions correctly within the cooling system. Preparations may include draining the coolant, removing the old tube, and inspecting the surrounding components for any damage or wear. It is important to follow manufacturer guidelines to achieve a secure and effective installation. Compatibility information regarding specific truck models and engine types will be provided separately to ensure the correct application of this component 1.

Maintenance and Troubleshooting

Regular maintenance practices for the Water Transfer Tube include periodic inspections for signs of wear, corrosion, or leaks. It is advisable to check the connections and fittings to ensure they remain tight and free from debris. Common issues that may arise include coolant leaks, which can be addressed by re-tightening connections or replacing damaged sections. Additionally, monitoring the overall cooling system performance can help identify potential problems early, allowing for timely interventions 2.

Safety Considerations

When working with the Water Transfer Tube, it is important to observe several safety guidelines. This includes allowing the engine and cooling system to cool down before beginning any maintenance or installation procedures to avoid burns from hot components. Additionally, ensuring that the system is properly pressurized and free from leaks is crucial to prevent coolant loss and maintain efficient cooling performance. Always follow safety protocols and use appropriate personal protective equipment when performing maintenance tasks 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive and heavy-duty truck industry. The company’s commitment to excellence is reflected in its extensive range of components and systems designed to enhance the performance and efficiency of heavy-duty engines.

Water Transfer Tube (Part 3897918) in Cummins Engines

The Water Transfer Tube, identified by part number 3897918, is a critical component in the cooling system of various Cummins engines. This part facilitates the transfer of coolant between different sections of the engine, ensuring efficient heat dissipation and maintaining optimal operating temperatures.

K50 Series Engines

In the K50 series engines, the Water Transfer Tube is integral to the engine’s cooling system. It connects the water pump to the radiator, allowing coolant to circulate effectively. This tube is designed to withstand high pressures and temperatures, ensuring durability and reliability under demanding conditions.

Group Applications

The Water Transfer Tube is also utilized in several engine groups where it serves the same fundamental purpose. In these groups, the tube is engineered to meet the specific cooling requirements of the engines, ensuring that heat is efficiently transferred away from the engine block to the radiator.

The design and placement of the Water Transfer Tube in these engines are crucial for maintaining the engine’s performance and longevity. Its role in the cooling system cannot be overstated, as it directly impacts the engine’s ability to operate within safe temperature ranges.

Role of Part 3897918 Water Transfer Tube in Engine Systems

The part 3897918 Water Transfer Tube is an essential component in the efficient operation of engine systems, particularly in the management and circulation of water within the system. This component is designed to facilitate the smooth transfer of water from the manifold to various parts of the engine, ensuring optimal cooling and performance.

Integration with the Manifold

The Water Transfer Tube connects directly to the manifold, which is a key component in the engine’s air intake system. The manifold distributes air to the cylinders, and the Water Transfer Tube ensures that water is readily available for cooling purposes. This connection is vital for maintaining the correct temperature within the manifold, preventing overheating and ensuring consistent engine performance.

Water Circulation through Tubes

Once connected to the manifold, the Water Transfer Tube extends to other critical areas of the engine, such as the cylinders and the exhaust system. The tube’s design allows for efficient water flow, reducing the risk of hotspots and ensuring that all components receive adequate cooling. This consistent water circulation is essential for the longevity and reliability of the engine.

Water Transfer Connection

The Water Transfer Connection points are strategically placed along the Water Transfer Tube to link with other water tubes within the engine system. These connection points are engineered to provide a secure and leak-free interface, ensuring that water is transferred without loss. This setup is particularly important in high-performance engines where precise cooling is necessary to maintain efficiency and power output.

Overall Function in Water Transfer

The primary function of the part 3897918 Water Transfer Tube is to enhance the overall water transfer process within the engine. By providing a dedicated pathway for water, it ensures that cooling water reaches all necessary components promptly. This not only aids in temperature regulation but also contributes to the overall stability and performance of the engine system.

Conclusion

In summary, the Water Transfer Tube plays a significant role in the intricate network of components that make up an engine’s cooling system. Its efficient design and strategic placement ensure that water is effectively circulated, contributing to the engine’s durability and operational efficiency.

-

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ ↩ -

Hilgers, M. (2023). Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature.

↩ ↩ -

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.