This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction To Water Transfer Connections

Water transfer connections are essential components in the cooling systems of commercial trucks and heavy-duty vehicles. These components facilitate the movement of coolant between various parts of the engine, ensuring optimal temperature regulation and preventing overheating. For engineers and mechanics, understanding the functionality and importance of these connections is crucial for maintaining the efficiency and reliability of the vehicle’s engine 2.

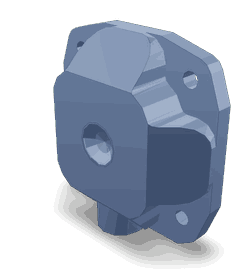

The Role Of Cummins Part #3920946

The Cummins Water Transfer Connection Part #3920946 is specifically engineered to manage the flow of coolant within the engine’s cooling system. This part ensures that the coolant is efficiently circulated, maintaining the engine’s temperature within safe operating limits. By doing so, it helps prevent engine damage and ensures the longevity of the vehicle’s components. The precise design and robust construction of this part make it an essential element in the cooling system, contributing to the overall performance and durability of the engine 3.

How The Cummins Water Transfer Connection Works

The Cummins Water Transfer Connection operates by connecting different sections of the engine’s cooling system. It allows coolant to flow from the radiator to the engine block and back, effectively dissipating heat generated by the engine. This process is critical in maintaining the engine’s performance and efficiency. The connection ensures a seamless flow of coolant, which is essential for consistent temperature regulation, especially under demanding operating conditions 4.

Importance In Truck Operations

In the context of commercial trucks and heavy-duty vehicles, the Water Transfer Connection plays a pivotal role. It ensures that the engine remains at an optimal temperature, even under heavy loads and varying environmental conditions. This is particularly important for long-haul trucking, where consistent engine performance is essential for safety and efficiency. The reliable operation of this component directly impacts the vehicle’s ability to perform under stress, making it a critical part of the engine system 1.

Troubleshooting And Maintenance

Regular maintenance of the Water Transfer Connection is crucial to prevent issues such as leaks or blockages, which can lead to engine overheating. Mechanics should inspect the connection for signs of wear, corrosion, or damage during routine maintenance checks. If any issues are detected, the connection should be repaired or replaced promptly to avoid potential engine damage. Additionally, ensuring that the coolant is clean and at the proper level is essential for the efficient operation of the cooling system 2.

Cummins: A Leader In Engine Technology

Cummins is renowned for its high-quality engine components and innovative solutions in the automotive and heavy-duty truck industries. The company’s commitment to excellence and reliability is reflected in its Water Transfer Connections, which are designed to meet the rigorous demands of commercial truck operations. Cummins parts are known for their durability, performance, and compatibility with a wide range of engine systems, making them a preferred choice for professionals in the field 3.

Conclusion

Understanding the Cummins Water Transfer Connection Part #3920946 is essential for anyone involved in the maintenance and operation of commercial trucks and heavy-duty vehicles. By ensuring the proper functioning of this component, engineers, mechanics, and fleet operators can maintain the efficiency and reliability of their vehicles, ultimately contributing to safer and more productive operations. The importance of this part in the cooling system cannot be overstated, and its proper maintenance is crucial for the longevity and performance of the engine 4.

-

John Dixon, Modern Diesel Technology Preventive Maintenance and Inspection, Delmar Cengage Learning, 2010.

↩ -

Sean Bennett, Modern Diesel Technology: Light Duty Diesels, Cengage Learning, 2012.

↩ ↩ -

Meherwan P Boyce, Gas Turbine Engineering Handbook 4th Edition, Butterworth-Heinemann, 2011.

↩ ↩ -

Tigran Parikyan Ed, Advances in Engine and Powertrain Research and Technology, Springer Nature, 2022.

↩ ↩

SPECIFICATIONS

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| Expansion Plug | 1 | 3007636 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.