This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Water Inlet Tube 4000870 by Cummins is a component designed to facilitate the efficient operation of the cooling system in heavy-duty trucks. This part is integral to maintaining optimal engine temperature by ensuring a consistent flow of coolant. Cummins, a well-established manufacturer in the automotive industry, produces this component with a focus on durability and performance 1.

Function and Operation

The Water Inlet Tube 4000870 operates by directing coolant into the engine block, where it absorbs heat generated during combustion. The coolant then circulates through the engine, picking up additional heat before returning to the radiator for cooling. This continuous cycle helps maintain the engine at a stable operating temperature, which is vital for performance and longevity. The tube’s design ensures a smooth and uninterrupted flow of coolant, minimizing the risk of blockages or leaks 2.

Key Features

This Cummins part is constructed from high-quality materials that resist corrosion and wear, ensuring long-term reliability. Its design includes precise fittings and connections that align with the engine’s cooling system components, promoting a secure and efficient fit. Additionally, the tube features smooth internal surfaces that reduce turbulence in the coolant flow, enhancing the overall efficiency of the cooling process 3.

Benefits

Utilizing the Water Inlet Tube 4000870 offers several advantages. It contributes to improved coolant flow, which is crucial for effective heat dissipation. This, in turn, provides enhanced engine protection against overheating, a common issue in heavy-duty applications. Furthermore, the consistent coolant flow supports overall engine efficiency and can contribute to extended engine life by maintaining optimal operating temperatures 4.

Installation

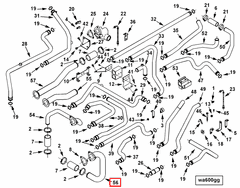

Proper installation of the Water Inlet Tube 4000870 involves several steps to ensure it functions correctly within the engine cooling system. Begin by ensuring the engine is cool and the cooling system is drained. Inspect the installation area for any debris or obstructions. Use the appropriate tools to remove the old tube and install the new one, ensuring all connections are tight and secure. Finally, refill the cooling system with the recommended coolant and check for any leaks.

Maintenance and Troubleshooting

Regular maintenance of the Water Inlet Tube 4000870 is important to ensure its continued performance. This includes periodic inspections for signs of wear, corrosion, or leaks. If any issues are detected, such as coolant leaks or irregular coolant flow, it may be necessary to clean or replace the tube. Following the manufacturer’s guidelines for maintenance can help prevent common problems and ensure the cooling system operates efficiently.

Safety Considerations

When handling, installing, or maintaining the Water Inlet Tube, it is important to observe safety guidelines to prevent injury or damage. Ensure the engine is cool before beginning any work to avoid burns from hot components. Use appropriate personal protective equipment, such as gloves and safety glasses, to protect against coolant and debris. Follow all manufacturer instructions and safety recommendations to ensure a safe working environment.

Cummins Overview

Cummins Inc. is a leading manufacturer in the heavy-duty truck industry, known for its commitment to quality and innovation. With a history of producing reliable and high-performance components, Cummins has established a strong reputation among professionals and enthusiasts alike. The company’s product range includes a variety of engine and powertrain components designed to meet the demanding requirements of heavy-duty applications. Cummins’ dedication to excellence is evident in every product they manufacture, including the Water Inlet Tube 4000870.

Water Inlet Tube (Part 4000870) Compatibility with Cummins Engines

The Water Inlet Tube, identified by part number 4000870, is a critical component in the cooling system of certain Cummins engines. This part is designed to facilitate the flow of coolant into the engine, ensuring optimal thermal management and performance.

QSK45 CM500 and QSK60 CM500 Engines

The Water Inlet Tube (4000870) is specifically engineered to fit seamlessly with the QSK45 CM500 and QSK60 CM500 engines. These engines are part of Cummins’ QSK series, which is renowned for its robust design and reliability in demanding applications. The inlet tube’s precise fitment ensures efficient coolant flow, which is essential for maintaining the engine’s operating temperature within the desired range.

The QSK45 CM500 and QSK60 CM500 engines are designed for heavy-duty applications, often found in marine, industrial, and power generation sectors. The Water Inlet Tube (4000870) is crafted to withstand the high pressures and temperatures associated with these demanding environments. Its compatibility with these engines ensures that the cooling system operates efficiently, contributing to the overall longevity and performance of the engine.

Role of Part 4000870 Water Inlet Tube in Engine Systems

The Water Inlet Tube 4000870 is an essential component in various engine systems, facilitating the efficient operation of several key elements.

In the design of engine cooling systems, the Water Inlet Tube directs coolant flow into the engine block, ensuring that the coolant circulates effectively to dissipate heat generated during combustion. This helps maintain optimal engine temperature and prevents overheating.

When considering alternative cooling methods, such as liquid cooling in performance engines, the Water Inlet Tube plays a significant role. It ensures that the alternative coolant, which may have different properties than traditional coolants, is properly introduced into the engine, enhancing cooling efficiency and performance.

In the context of plumbing within the engine system, the Water Inlet Tube connects to various components such as the radiator, thermostat housing, and water pump. This connection is vital for maintaining a sealed and efficient coolant pathway, which is essential for the overall integrity of the cooling system.

For engines equipped with an aftercooler, the Water Inlet Tube is integral to the aftercooling process. It supplies coolant to the aftercooler, where it helps reduce the temperature of compressed air before it enters the combustion chamber. This not only improves engine efficiency but also enhances the overall performance and longevity of the engine by preventing thermal stress on components.

Conclusion

The Water Inlet Tube 4000870 by Cummins is a vital component in the cooling systems of heavy-duty engines, ensuring efficient coolant flow and optimal thermal management. Its high-quality construction, precise design, and compatibility with Cummins engines make it a reliable choice for maintaining engine performance and longevity. Proper installation, regular maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this part.

-

Eret, A. (2024). Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature.

↩ -

Wright, G. (2015). Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning.

↩ -

Sander, F. (2007). Diesel Mechanics, First Edition. Global Media.

↩ -

Ling, F. F. (2011). The Automotive Body. Springer Science.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.