This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

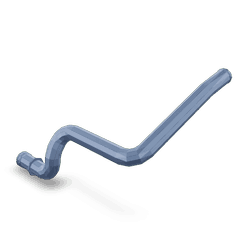

The Water Transfer Tube (Part #4016066) by Cummins is a component designed to facilitate the efficient transfer of coolant within the cooling system of commercial trucks. Its role is significant in maintaining the optimal operating temperature of the engine, which is vital for the performance and longevity of the vehicle 2.

Basic Concepts and Functionality

Water transfer tubes operate on the fundamental principle of fluid dynamics within a closed system. In the context of a truck’s cooling system, these tubes direct the flow of coolant from the engine to the radiator and back. This circulation helps dissipate heat generated by the engine, ensuring that it remains within safe operating temperatures. This part is engineered to enhance this process by providing a reliable pathway for coolant movement 1.

Purpose and Role in Truck Operation

This Cummins part serves a specific function within the cooling system of commercial trucks. It is responsible for transferring coolant between the engine and the radiator, playing a role in the engine cooling system by maintaining a consistent flow of coolant. This consistent flow contributes to efficient engine performance and helps prevent overheating, which can lead to engine damage over time 2.

Key Features

The Water Transfer Tube is characterized by several design elements and material choices that enhance its performance and durability. It is constructed from high-quality materials resistant to corrosion and high temperatures, ensuring longevity in demanding environments. The tube’s design includes precise fittings and connections that facilitate a secure and leak-free installation, contributing to the overall efficiency of the cooling system 2.

Benefits

The advantages of the Water Transfer Tube include improved cooling efficiency, which helps maintain optimal engine temperature under various operating conditions. By ensuring a consistent flow of coolant, it reduces the risk of engine overheating. Additionally, the tube’s durable construction and reliable performance contribute to the enhanced overall reliability of the truck’s cooling system 2.

Troubleshooting and Maintenance

Common issues with the Water Transfer Tube may include leaks or blockages, which can impede the flow of coolant. Regular inspection for signs of wear, corrosion, or damage is recommended. Maintenance practices should include checking for proper connections and ensuring the tube is free from obstructions. Addressing any issues promptly can help maintain optimal performance and longevity of the cooling system 2.

Installation Considerations

When installing the Water Transfer Tube, it is important to consider compatibility with the specific truck model to ensure a proper fit. Following manufacturer guidelines for fitting procedures is crucial to avoid leaks and ensure efficient coolant flow. Specific installation requirements may include the use of sealants or gaskets to achieve a secure connection 2.

Performance Optimization

To maximize the performance of the Water Transfer Tube, regular inspection and cleaning are recommended. Monitoring coolant levels and ensuring they are within the manufacturer’s specifications is important for maintaining efficient cooling. Addressing any signs of wear or damage promptly can prevent more significant issues and contribute to the longevity of the cooling system 2.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the automotive industry, known for its high-quality components for commercial vehicles. With a history of innovation and a commitment to excellence, Cummins has established a reputation for producing reliable and durable parts that contribute to the performance and efficiency of commercial trucks. The company’s dedication to quality is evident in its wide range of products, including the Water Transfer Tube 2.

Compatibility with Cummins Engines

This part is a critical component in the cooling system of various Cummins engines. It is designed to facilitate the transfer of coolant between different sections of the engine, ensuring efficient thermal management and preventing overheating 2.

Cummins QSK45 Engine

In the Cummins QSK45 engine, the Water Transfer Tube plays a vital role in maintaining the optimal operating temperature. This engine is known for its robust performance and reliability, often used in heavy-duty applications such as marine and industrial settings. The tube ensures that coolant is evenly distributed, which is crucial for the longevity and efficiency of the engine 2.

Cummins CM500 Engine

Similarly, in the Cummins CM500 engine, the Water Transfer Tube is integral to the cooling system. This engine is typically employed in power generation applications, where consistent and reliable performance is paramount. The tube’s design allows for effective coolant circulation, which helps in maintaining the engine’s temperature within the specified range, thereby enhancing its operational lifespan 2.

Group Compatibility

The Water Transfer Tube is also compatible with other Cummins engines within the same family or similar cooling system configurations. This ensures that the tube can be used across various models, providing a standardized solution for maintaining engine temperature. The compatibility extends to engines that share similar design principles and cooling requirements, ensuring that the tube fits seamlessly and performs its function effectively 2.

Role of Part 4016066 Water Transfer Tube in Engine Systems

The Water Transfer Tube is an essential component in the efficient operation of engine systems, particularly in those equipped with aftercoolers. This component is integral to the plumbing system, ensuring the seamless transfer of water between various parts of the engine 2.

Integration with Plumbing Systems

In the plumbing system of an engine, the Water Transfer Tube facilitates the movement of water from one point to another. This is vital for maintaining the correct water levels and pressure within the system. The tube connects to various plumbing components, allowing for the circulation of water that is used for cooling and other functions within the engine 2.

Function in Aftercooler Water Systems

The aftercooler is a device used to cool the air that has been compressed by the turbocharger before it enters the engine’s combustion chambers. The Water Transfer Tube plays a significant role in the aftercooler water system by transferring water to and from the aftercooler. This ensures that the aftercooler maintains optimal temperature levels, which is essential for the efficient operation of the turbocharger and the overall performance of the engine 2.

The tube is designed to handle the specific flow rates and pressures required by the aftercooler, ensuring that the cooling process is effective. It connects to the aftercooler’s inlet and outlet ports, allowing water to flow through the aftercooler core where it absorbs heat from the compressed air. The cooled water then exits the aftercooler and is either recirculated or discharged from the system, depending on the engine’s design 2.

Overall System Contribution

By efficiently transferring water within the engine’s plumbing and aftercooler systems, the Water Transfer Tube contributes to the stable operation of the engine. It helps in maintaining the desired temperature levels, which is important for the longevity and performance of the engine components. The tube’s reliable function is a testament to the importance of each component within the complex network of an engine system 2.

Conclusion

The Water Transfer Tube (Part #4016066) by Cummins is a critical component in the cooling systems of commercial trucks and various Cummins engines. Its design and functionality are essential for maintaining optimal engine temperature, ensuring efficient performance, and preventing overheating. Regular maintenance and proper installation are key to maximizing the benefits of this part, contributing to the overall reliability and longevity of the engine systems in which it is used 2.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.