This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

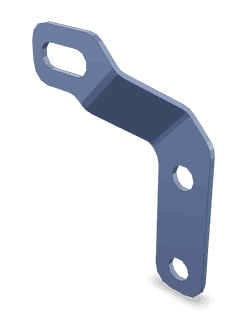

The Water Tube Bracket, identified by Part #4016397, is a component manufactured by Cummins, a well-established name in the automotive industry. This bracket is integral to the operation of heavy-duty truck engines, particularly within the engine cooling system. Its role is to support and secure the water tubes, ensuring efficient coolant flow and maintaining the structural integrity of the cooling system 1.

Function and Operation

The Water Tube Bracket operates by securing the water tubes in the engine cooling system. It ensures that the tubes remain in the correct position, which is vital for the proper circulation of coolant. This circulation is necessary for dissipating heat generated by the engine, thereby maintaining optimal operating temperatures. Additionally, the bracket contributes to the structural integrity of the cooling system by providing a stable mounting point for the water tubes 2.

Key Features

This Cummins part is designed with specific characteristics to enhance its performance and longevity. It is constructed from materials that offer durability and resistance to corrosion, ensuring it can withstand the harsh conditions present in heavy-duty truck engines. The design of the bracket is tailored to fit Cummins engines precisely, guaranteeing compatibility and efficient operation within the cooling system 3.

Benefits

Incorporating the Water Tube Bracket into the engine cooling system offers several advantages. It contributes to improved engine performance by ensuring consistent and efficient coolant flow. This consistent flow helps in maintaining engine temperatures within the desired range, enhancing the engine’s reliability. Furthermore, the robust design of the bracket reduces the need for frequent maintenance, offering a cost-effective solution for heavy-duty truck operators.

Installation and Maintenance

Proper installation of the Water Tube Bracket is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines, which include specific torque specifications and alignment procedures to ensure it is securely fastened and correctly positioned. Regular maintenance checks are recommended to ensure the bracket remains in good condition, which includes inspecting for any signs of wear, corrosion, or damage that could affect its performance.

Troubleshooting Common Issues

Typical issues associated with the Water Tube Bracket may include leaks or structural damage. These problems can often be identified through routine inspections. If a leak is detected, it may be necessary to replace the bracket or the water tubes to restore the integrity of the cooling system. Structural damage may require a more thorough assessment to determine the appropriate repair or replacement strategy.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and customer satisfaction in the automotive industry. The company’s product offerings extend beyond engines to include a wide range of components and systems designed to enhance the performance and efficiency of vehicles and equipment.

Role of Part 4016397 Water Tube Bracket in Engine Systems

The 4016397 Water Tube Bracket is an integral component in the assembly and functionality of various engine systems. Its primary role is to provide a secure mounting point for water tubes within the engine’s plumbing system. This ensures that the water tubes are correctly positioned and supported, which is essential for the efficient operation of the engine’s cooling and aftercooling systems.

In the context of engine design, the Water Tube Bracket allows for precise alignment of water tubes, which are responsible for circulating coolant through the engine. This alignment is vital for maintaining consistent coolant flow, which helps in regulating engine temperature and preventing overheating.

When considering alternative setups or upgrades, the Water Tube Bracket can be utilized in conjunction with an upfit kit. For instance, the Rubber T-Piece Upfit Kit can be integrated with the bracket to modify the plumbing configuration. This adaptation can enhance the engine’s performance by optimizing coolant distribution and reducing the risk of leaks.

Furthermore, in aftercooler systems, the Water Tube Bracket plays a significant role. Aftercoolers rely on efficient water circulation to cool the compressed air before it enters the engine. The bracket ensures that the water tubes in the aftercooler are securely held in place, allowing for effective heat exchange and improved engine efficiency.

Conclusion

The Water Tube Bracket, part 4016397, is a fundamental component that supports the structural integrity and operational efficiency of engine systems by ensuring proper alignment and support of water tubes in both standard and modified configurations. Its role in maintaining optimal engine temperature and performance cannot be overstated, making it a critical part of the engine cooling system.

-

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.