This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

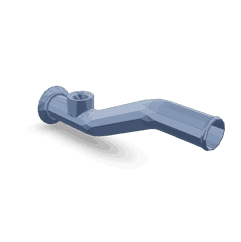

The Cummins 4016407 Water Bypass Tube is a component designed for use in the engine cooling systems of commercial trucks. Its purpose is to facilitate the efficient circulation of coolant within the engine, ensuring that the engine operates within optimal temperature ranges. This part interacts with other cooling system components to maintain engine performance and prevent overheating 1.

Function and Operation

The Water Bypass Tube operates by providing an alternative path for coolant flow within the engine cooling system. When the thermostat is closed, the bypass tube allows coolant to circulate between the engine block and the radiator, ensuring that the engine does not overheat. This component works in conjunction with the thermostat and radiator to regulate coolant flow based on engine temperature 2.

Purpose of the Water Bypass Tube

The specific role of the Water Bypass Tube is to maintain optimal engine temperature by allowing coolant to bypass the thermostat when it is closed. This ensures that the engine receives a continuous flow of coolant, which is vital for efficient performance and preventing overheating. By facilitating consistent coolant circulation, the bypass tube contributes to the overall reliability and longevity of the engine 3.

Key Features

The Cummins 4016407 Water Bypass Tube is constructed from durable materials that are resistant to corrosion and high temperatures. Its design includes precise fittings and connections to ensure a secure and leak-free installation. The tube’s robust construction enhances its performance and longevity in demanding operating conditions.

Benefits

Using the Cummins 4016407 Water Bypass Tube offers several advantages. It contributes to improved engine efficiency by ensuring consistent coolant flow, which helps maintain optimal engine temperature. The durable construction of the bypass tube enhances its reliability and longevity, providing peace of mind for fleet operators. Additionally, its design allows for efficient operation in various operating conditions, making it a valuable component for commercial truck engines.

Installation Considerations

When installing the Water Bypass Tube, it is important to follow manufacturer guidelines to ensure a proper fit and function. Preparatory steps may include cleaning the installation area and inspecting other cooling system components for any signs of wear or damage. Tools required for installation may include wrenches and sealants. Common pitfalls to avoid include improper alignment and over-tightening, which can lead to leaks or damage to the bypass tube.

Troubleshooting and Maintenance

To identify common issues related to the Water Bypass Tube, operators should monitor engine temperature and look for signs of coolant leaks. Diagnostic procedures may involve inspecting the bypass tube for blockages or damage. Regular maintenance practices, such as flushing the cooling system and replacing worn components, can help ensure the longevity and optimal performance of the Water Bypass Tube.

Common Failure Modes

Typical failure modes associated with the Water Bypass Tube include blockages, leaks, and corrosion. Symptoms of failure may include overheating, coolant leaks, or inconsistent engine temperature. Causes of failure can range from manufacturing defects to wear and tear over time. Recommended corrective actions include replacing the bypass tube and inspecting other cooling system components for damage.

Manufacturer Information - Cummins

Cummins Inc. is a leading manufacturer of diesel engines, known for its high-quality products and innovative solutions in the commercial truck industry. With a history of providing reliable and efficient engine components, Cummins has established a strong reputation among fleet operators and maintenance professionals. The company’s product range includes a variety of engine parts and systems designed to enhance performance and reliability in demanding applications.

Compatibility with Cummins Engines

The Water Bypass Tube, identified by part number 4016407, is compatible with various Cummins engines, including the QSK45 CM500, QSK60 CM500, QSK60 CM850 MCRS, and QSK60G. This compatibility is due to the common design and engineering principles within the QSK series, allowing for the interchangeability of certain components, including the water bypass tube, across different models within the series. This design choice enhances the ease of maintenance and repair, as technicians can use the same part for multiple engine models, reducing inventory complexity and costs.

Integration with Engine Systems

The 4016407 Water Bypass Tube is strategically placed in engine systems to facilitate the smooth transition of water from one component to another. This integration is vital for maintaining the integrity of the plumbing system, preventing leaks, and ensuring that water reaches all necessary areas without obstruction. In aftercooler water systems, the bypass tube enhances cooling efficiency by allowing for the regulated flow of water through the aftercooler. In auxiliary cooling systems, it ensures that critical components receive adequate cooling, thereby preventing overheating and potential damage.

Conclusion

The Cummins 4016407 Water Bypass Tube plays a crucial role in the efficient operation of engine cooling systems by ensuring consistent coolant flow and maintaining optimal engine temperature. Its durable construction and compatibility with various Cummins engines make it a reliable and valuable component for commercial truck applications. Proper installation, regular maintenance, and timely replacement of the bypass tube are essential for ensuring the longevity and performance of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.