This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

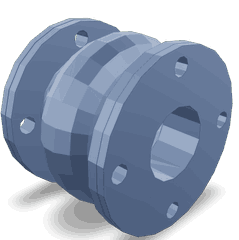

The Cummins 4020120 Water Transfer Connection is a vital component in commercial trucks, specifically designed for the vehicle’s cooling system. This part facilitates the efficient transfer of coolant, ensuring optimal engine temperature and reliable cooling system operation.

Purpose and Function

The Water Transfer Connection’s primary function is to enable the smooth transfer of coolant within the truck’s cooling system. It connects various system components, allowing coolant to circulate from the engine to the radiator and back. This process is essential for dissipating heat generated during engine operation, maintaining engine temperature within safe limits, and contributing to engine efficiency and longevity 1.

Key Features

This Cummins part is characterized by its robust design and high-quality materials, engineered to withstand the high temperatures and pressures of a truck’s cooling system. It features precision-machined fittings and seals for a secure, leak-free connection, enhancing coolant transfer efficiency 2.

Benefits

Incorporating the 4020120 Water Transfer Connection into a truck’s cooling system offers improved coolant flow, crucial for effective heat management. It enhances engine cooling efficiency, maintaining optimal engine temperatures under various operating conditions. The reliable performance of this connection contributes to the overall dependability of the truck’s cooling system 3.

Installation and Integration

Proper installation of the 4020120 Water Transfer Connection is essential for its effective operation. It should be installed according to the manufacturer’s guidelines, ensuring correct placement and secure connections. This involves aligning the connection with the corresponding components in the cooling system and tightening it to the specified torque. Careful attention to these details during installation helps prevent leaks and ensures efficient coolant transfer.

Maintenance and Troubleshooting

Routine maintenance of the 4020120 Water Transfer Connection is important for its continued optimal performance. This includes regular inspections for signs of wear or damage and ensuring that all connections remain tight and secure. In case of issues related to coolant flow or connection integrity, troubleshooting may involve checking for leaks, assessing the condition of the seals, and ensuring that the connection is properly aligned and tightened.

Manufacturer - Cummins

Cummins is a renowned manufacturer in the automotive industry, known for its high-quality engine components. The company’s commitment to quality is evident in the design and construction of the 4020120 Water Transfer Connection, reflecting Cummins’ reputation for durability and performance in demanding applications.

Water Transfer Connection Part 4020120 and Cummins Engines

The Water Transfer Connection part 4020120 by Cummins is a critical component in the cooling system of several Cummins engine models. This part facilitates the transfer of water between different parts of the engine’s cooling system, ensuring efficient heat dissipation and maintaining optimal operating temperatures.

K38 and K50 Engines

The K38 and K50 engines, known for their robust design and reliability, incorporate the 4020120 Water Transfer Connection to manage the flow of coolant. This ensures that the engine operates within its specified thermal parameters, enhancing longevity and performance.

QSK50 CM2150 and QSK50 CM2150 MCRS Engines

The QSK50 CM2150 and QSK50 CM2150 MCRS engines, widely used in various industrial applications, also utilize the 4020120 Water Transfer Connection. This part is integral to the cooling system, providing a seamless transfer of coolant to prevent overheating and maintain efficiency.

QSK60 CM850 MCRS Engine

The QSK60 CM850 MCRS engine, designed for heavy-duty applications, relies on the 4020120 Water Transfer Connection to manage its cooling system effectively. This ensures that the engine can handle high-stress conditions while maintaining optimal performance and reliability.

K107 Engine

The K107 engine, another robust model in the Cummins lineup, incorporates the 4020120 Water Transfer Connection to manage its cooling system. This ensures that the engine can operate efficiently under various conditions, providing the necessary thermal management for sustained performance.

Role of Part 4020120 Water Transfer Connection in Engine Systems

The 4020120 Water Transfer Connection is integral to the efficient operation of various engine systems by facilitating the seamless transfer of water between different components. This component ensures that water flows correctly through the system, maintaining optimal performance and cooling.

Integration with Key Components

-

Auxiliary Cooling System:

- The Water Transfer Connection interfaces with the auxiliary cooling inlet and outlet, allowing for the circulation of coolant through the auxiliary cooling system. This is essential for maintaining the temperature of sensitive engine components that the primary cooling system may not adequately address.

-

Raw Water System:

- It connects to the raw water inlet and outlet, enabling the passage of raw water—typically drawn from a seawater source—through the engine’s raw water pump. This raw water is used for initial cooling before it is processed further.

-

Heat Exchanger:

- The connection plays a role in directing water flow to and from the heat exchanger. The heat exchanger uses the raw water to cool the engine’s primary coolant, ensuring that the engine operates within safe temperature ranges.

-

Raw Water Pump:

- By linking to the raw water pump, the Water Transfer Connection ensures a consistent supply of raw water is available for the cooling process. This pump is responsible for drawing in seawater or freshwater and pushing it through the system.

-

Seawater System:

- In marine applications, the connection is vital for integrating the seawater cooling system. It allows for the efficient transfer of seawater to cool the engine, leveraging the abundant natural resource available in maritime environments.

Through these connections, the Water Transfer Connection ensures that water is effectively routed throughout the engine system, supporting the cooling processes necessary for sustained engine performance and longevity.

Conclusion

The Cummins 4020120 Water Transfer Connection is a critical component in the cooling systems of commercial trucks and various Cummins engines. Its robust design, high-quality materials, and precise engineering ensure efficient coolant transfer, maintaining optimal engine temperatures and contributing to the overall reliability and performance of the cooling system. Proper installation, regular maintenance, and troubleshooting are essential for the continued effective operation of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.