This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Water Transfer Tube (Part #4062891) by Cummins is a component designed to enhance the efficiency of heavy-duty truck systems. It plays a role in maintaining optimal engine operation by facilitating the transfer of coolant within the engine cooling system. This part is integral to ensuring that the engine operates within safe temperature ranges, thereby contributing to the overall performance and longevity of the truck 1.

Basic Concepts and Functionality

The Water Transfer Tube operates on the fundamental principle of fluid dynamics within the cooling system. Its purpose is to direct coolant flow from the engine to the radiator and back, ensuring that heat is effectively dissipated. The tube interacts with other components such as the water pump, thermostat, and radiator to maintain a consistent coolant circulation. This circulation is vital for dissipating heat generated by the engine, which if not managed properly, could lead to overheating and potential engine damage 2.

Purpose of the Water Transfer Tube

In the operation of a truck, the Water Transfer Tube serves a significant function within the engine cooling system. It ensures that coolant is evenly distributed throughout the engine, absorbing heat as it circulates. This consistent coolant flow helps in maintaining engine temperature within optimal ranges, which is crucial for engine performance and longevity. By facilitating efficient heat transfer, the tube contributes to the stability and reliability of the engine under various operating conditions 3.

Key Features

The Water Transfer Tube is characterized by its robust design and the materials used in its construction. Typically made from durable materials such as high-grade rubber or synthetic compounds, the tube is designed to withstand the high temperatures and pressures within the cooling system. Its flexibility allows it to fit snugly within the engine compartment, ensuring a secure connection between components. Additionally, the tube may feature reinforced sections to enhance durability and prevent leaks, which are common failure points in cooling systems.

Benefits

The advantages provided by the Water Transfer Tube include improved cooling efficiency, which directly contributes to reduced risk of engine overheating. By ensuring consistent coolant flow, the tube helps in maintaining engine temperature, which is critical for optimal performance. Furthermore, its durable construction enhances the reliability of the cooling system, especially in demanding operating conditions where engines are subjected to high loads and temperatures.

Installation and Integration

Proper installation of the Water Transfer Tube within the truck’s cooling system is crucial for ensuring optimal performance. It should be installed according to the manufacturer’s guidelines, ensuring that all connections are secure and that the tube is properly routed to avoid kinks or obstructions. Attention to detail during installation helps in preventing coolant leaks and ensures that the tube functions effectively within the system.

Maintenance and Troubleshooting

Maintaining the Water Transfer Tube is key to ensuring its longevity and performance. Regular inspection procedures should be conducted to check for signs of wear, cracking, or leaks. Common issues to watch for include brittleness due to age or exposure to high temperatures, and physical damage from engine vibrations. Troubleshooting tips for addressing potential problems include replacing the tube if signs of degradation are detected, and ensuring that all connections are tight and secure.

Compatibility and Applications

The Water Transfer Tube is designed for specific types of trucks and engine models. It is important to verify compatibility to ensure optimal performance and integration within the cooling system. Specific applications may vary, and it is advisable to consult the manufacturer’s guidelines or a professional technician to confirm compatibility with the intended truck and engine model.

Cummins: A Brief Overview

Cummins Inc. is a leader in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a history of developing reliable and high-performance engines and components, Cummins has established a strong reputation in the market. The company’s product range includes a variety of engine types and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications. Cummins’ dedication to excellence is reflected in its continued investment in research and development, ensuring that its products remain at the forefront of technology and performance in the industry.

Water Transfer Tube (Part 4062891) Compatibility with Cummins Engines

The Water Transfer Tube, identified by the part number 4062891, is a critical component in the cooling system of various Cummins engines. This part is designed to facilitate the transfer of coolant between different sections of the engine, ensuring efficient heat dissipation and maintaining optimal operating temperatures.

G855 Engine Series

The G855 engine series, known for its robust performance and reliability, incorporates the Water Transfer Tube as part of its cooling system architecture. This part is integral to the engine’s design, ensuring that the coolant flows seamlessly between the engine block and the radiator. The G855 engines are typically used in heavy-duty applications, where efficient cooling is paramount to prevent overheating and maintain engine longevity.

Other Cummins Engines

Beyond the G855 series, the Water Transfer Tube (part 4062891) is also compatible with a range of other Cummins engines. These engines, while varying in specifications and applications, share a common requirement for effective coolant transfer. The design of the Water Transfer Tube ensures that it fits snugly within the cooling system of these engines, providing a reliable pathway for coolant circulation.

The compatibility of the Water Transfer Tube with various Cummins engines underscores its versatility and importance in maintaining engine performance. Whether in the G855 series or other models, this part plays a crucial role in the engine’s cooling system, ensuring that the engine operates within safe temperature limits.

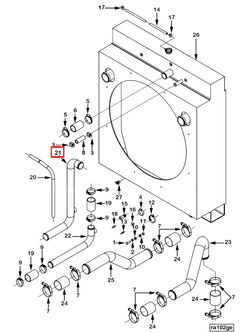

Role of Part 4062891 Water Transfer Tube in Engine Systems

The 4062891 Water Transfer Tube is an essential component in the cooling system of an engine, working in conjunction with several other parts to maintain optimal engine temperature.

Interaction with the Radiator

The Water Transfer Tube facilitates the movement of coolant between the engine and the radiator. The radiator, a heat exchanger, is responsible for dissipating the heat absorbed by the coolant as it circulates through the engine. The tube ensures a consistent flow of coolant to the radiator, where the heat is transferred to the ambient air, thus cooling the coolant before it returns to the engine. This continuous cycle is vital for preventing engine overheating.

Contribution to Engine Longevity

By ensuring efficient coolant circulation, the Water Transfer Tube plays a significant role in prolonging engine life. It helps in maintaining a stable engine temperature, which is essential for the proper functioning of engine components such as the cylinder head, pistons, and cylinder walls.

Support for Thermostat Function

The Water Transfer Tube also supports the thermostat’s role in regulating engine temperature. The thermostat controls the flow of coolant based on the engine’s temperature, and the tube ensures that this flow is unimpeded. This collaboration helps in achieving the desired engine operating temperature more quickly and maintains it throughout the engine’s operation.

Enhancement of Cooling System Efficiency

Incorporating the Water Transfer Tube into the engine’s cooling system enhances overall efficiency. It reduces the risk of coolant leaks and ensures that the coolant path is direct and unobstructed, which is essential for effective heat management.

Integration with Other Cooling System Components

Beyond the radiator, the Water Transfer Tube interacts with other components such as the water pump, hoses, and coolant reservoir. The water pump drives the coolant through the engine and into the radiator, while the hoses connect various parts of the cooling system. The coolant reservoir acts as a buffer, accommodating changes in coolant volume due to thermal expansion and contraction. The tube’s role in this network is to provide a reliable conduit for coolant flow, ensuring that all components function harmoniously.

Conclusion

The Water Transfer Tube (Part #4062891) by Cummins is a vital component in the cooling systems of heavy-duty trucks and engines. Its role in facilitating efficient coolant circulation ensures that engines operate within optimal temperature ranges, contributing to their performance and longevity. The tube’s robust design and compatibility with various Cummins engines highlight its importance in maintaining engine efficiency and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.