This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

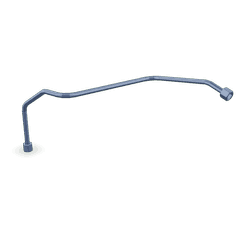

The Cummins 4094999 Tube Cap is a component designed for use in commercial truck systems. Its purpose is to provide a secure and reliable seal for various tubes and connections within the truck’s system. This part plays a role in maintaining the integrity and efficiency of the vehicle’s operations by ensuring that fluids and gases are properly contained and directed 3.

Purpose and Function

The primary function of the Cummins 4094999 Tube Cap is to seal the ends of tubes and prevent leaks. This is vital for the proper operation of the truck’s system, as it ensures that fluids and gases remain within their designated pathways. By maintaining a secure seal, the Tube Cap contributes to the overall efficiency and reliability of the vehicle, helping to prevent system failures and reduce the risk of accidents 1.

Key Features

The Cummins 4094999 Tube Cap is constructed from durable materials that are resistant to corrosion and wear. Its design includes precise threading and a tight-fitting cap to ensure a secure seal. Additionally, the Tube Cap may feature unique characteristics such as anti-vibration properties or compatibility with specific tube sizes, which enhance its performance in demanding environments 2.

Benefits

Using the Cummins 4094999 Tube Cap offers several benefits. It helps to improve system integrity by providing a reliable seal that prevents leaks. The durable construction of the Tube Cap enhances its longevity, reducing the need for frequent replacements. Over time, this can lead to cost savings for fleet operators. Additionally, the secure seal provided by the Tube Cap contributes to the overall efficiency of the truck’s system, potentially improving fuel economy and reducing maintenance costs 3.

Installation and Compatibility

Proper installation of the Cummins 4094999 Tube Cap is important to ensure optimal performance. It should be installed according to the manufacturer’s guidelines to achieve a secure seal. Compatibility with various truck models and systems is a key consideration, as it ensures that the Tube Cap will function effectively within the specific application. Operators should consult the manufacturer’s specifications to confirm compatibility with their truck’s system 4.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 4094999 Tube Cap is important to ensure its longevity and effectiveness. This may include periodic inspection for signs of wear or damage, and replacement if necessary. Common issues that may arise include leaks or a loose seal, which can often be addressed by re-tightening the cap or replacing it if damage is detected. Following the manufacturer’s maintenance guidelines can help to prevent these issues and ensure the Tube Cap continues to perform reliably 2.

Safety Considerations

When handling and installing the Cummins 4094999 Tube Cap, it is important to follow safety protocols to prevent accidents. This may include wearing appropriate personal protective equipment and ensuring that the truck’s system is depressurized before beginning work. Adhering to industry standards and manufacturer guidelines can help to ensure a safe working environment and prevent injuries 3.

Environmental Impact

The environmental impact of using the Cummins 4094999 Tube Cap can be influenced by the materials and manufacturing processes employed by Cummins. The use of eco-friendly materials and sustainable manufacturing practices can help to reduce the part’s environmental footprint. Operators should consider these factors when selecting components for their vehicles, as they can contribute to a more sustainable operation 3.

Customer Reviews and Feedback

Customer reviews and feedback on the Cummins 4094999 Tube Cap provide valuable insights into its performance and reliability in real-world applications. Many users report positive experiences with the Tube Cap, noting its durability and effectiveness in preventing leaks. This feedback can help potential buyers make informed decisions about whether this part is suitable for their needs 4.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor facilities and more than 7,200 dealer locations. The company’s product range includes engines for on-highway, off-highway, and marine applications, as well as filtration and power generation systems. Cummins is dedicated to advancing technology and improving the way the world moves.

Tube Cap 4094999 in Cummins Engines

The Tube Cap 4094999, manufactured by Cummins, is a critical component in several of their engine models. This part is integral to the engine’s operation, ensuring the integrity and functionality of the system it is part of.

QSK19 CM500

In the QSK19 CM500 engine, the Tube Cap 4094999 plays a pivotal role in maintaining the pressure and flow within the engine’s systems. Its precise fit and robust construction are essential for the engine’s performance and longevity. This part is designed to withstand the high pressures and temperatures typical of heavy-duty engines, ensuring reliable operation under demanding conditions.

Grouping of Engines

The Tube Cap 4094999 is not limited to the QSK19 CM500 engine but is also compatible with other Cummins engines within the same series. This compatibility ensures that the part can be used across multiple models, simplifying maintenance and repair processes. The design and specifications of the Tube Cap 4094999 are meticulously crafted to meet the stringent requirements of Cummins’ high-performance engines, ensuring that it fits seamlessly and functions optimally within the engine’s architecture.

Role of Part 4094999 Tube Cap in Plumbing and Compressor Coolant Systems

Plumbing Systems

In plumbing systems, the 4094999 Tube Cap is instrumental in ensuring the integrity and efficiency of fluid transfer. It is commonly used to seal the ends of pipes, preventing leaks and maintaining pressure within the system. This component is particularly important in applications where multiple pipes intersect, such as in complex residential or commercial plumbing networks. The Tube Cap helps in directing the flow of water or other fluids, ensuring that they reach their intended destinations without loss or contamination. Additionally, it plays a role in simplifying maintenance and repair processes by providing easy access points for inspection and component replacement.

Compressor Coolant Systems

In compressor coolant systems, the 4094999 Tube Cap serves a similarly vital function. These systems rely on efficient coolant flow to manage the heat generated by compressors, which are often used in refrigeration, air conditioning, and industrial processes. The Tube Cap is employed to seal the ends of coolant lines, ensuring that the coolant remains contained within the system. This containment is essential for maintaining the pressure and temperature stability required for optimal compressor performance. Furthermore, the Tube Cap aids in preventing coolant leaks, which can lead to system inefficiency and potential damage to the compressor. Its use in coolant systems also facilitates easier system diagnostics and maintenance, allowing for quick identification and resolution of issues related to coolant flow and pressure.

Conclusion

The Cummins 4094999 Tube Cap is a vital component in commercial truck systems, ensuring the integrity and efficiency of fluid and gas transfer within the vehicle. Its durable construction, precise fit, and compatibility with various systems make it a reliable choice for fleet operators. Regular maintenance and adherence to safety protocols are essential for maximizing the Tube Cap’s performance and longevity. Additionally, considering the environmental impact of the part and leveraging customer feedback can further enhance its effectiveness in real-world applications.

-

Tyres Suspension and Handling Second Edition, John C Dixon, SAE International, 1996

↩ -

Automotive Technician Training, Second Edition, Tom Denton and Hayley Pells, Routledge, 2022

↩ ↩ -

Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition, Robert Bosch GmbH, Springer Vieweg, 2007

↩ ↩ ↩ ↩ -

Owners Manual, Bulletin Number 5677029, Cummins Inc.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.