This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4095958 Water Transfer Tube is a critical component in the cooling systems of heavy-duty trucks, designed to facilitate the efficient transfer of coolant between the engine and the radiator. This ensures the engine operates within optimal temperature ranges, contributing to its performance and longevity through effective thermal management 1.

Basic Concepts of Water Transfer Tubes

A water transfer tube serves as a conduit for coolant flow within a truck’s cooling system, operating on the principle of convection. Coolant absorbs heat from the engine and transfers it to the radiator for dissipation into the environment. The efficiency of this process is essential for preventing engine overheating and ensuring consistent performance 2.

Purpose and Function

The Cummins 4095958 specifically ensures a continuous and efficient flow of coolant between the engine and the radiator. This transfer is vital for dissipating engine-generated heat, maintaining operational temperature, and protecting the engine from overheating damage.

Key Features

This Cummins part is characterized by a robust material composition to withstand high temperatures and pressures, a precise design for optimal coolant flow, and reinforced sections to prevent leaks and improve longevity.

Benefits

The advantages of the 4095958 include improved coolant flow, enhancing engine cooling efficiency. This contributes to overall engine performance and longevity by ensuring operation within the designed temperature range, reducing the risk of overheating and associated damage.

Installation and Compatibility

Proper installation of this part involves specific procedures to ensure secure fitting and intended function. Compatibility with various truck models and engine types is crucial, ensuring the tube is suitable for the specific application and contributes effectively to the cooling system’s performance.

Maintenance and Troubleshooting

Routine maintenance practices for the 4095958 are essential for optimal performance. This includes regular inspections for wear or damage, ensuring secure connections, and checking for proper coolant levels. Troubleshooting common issues such as leaks, blockages, or reduced coolant flow may involve inspecting the tube for physical damage, ensuring all connections are tight, and checking for obstructions within the cooling system.

Common Failure Modes

Typical failure modes for water transfer tubes include corrosion, cracking, or blockages. Factors contributing to these failures can include exposure to extreme temperatures, physical damage, or the presence of contaminants within the coolant. Preventive measures may involve using high-quality coolant, regular maintenance, and ensuring the cooling system is free from contaminants.

Upgrades and Modifications

Potential upgrades or modifications to the 4095958 can enhance performance or address specific operational requirements. These may include aftermarket options offering improved durability, enhanced coolant flow, or compatibility with modified engine setups. Evaluating the benefits of these upgrades involves considering the specific needs of the application and the potential improvements in cooling system performance.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive and heavy-duty truck industries, known for its commitment to innovation, quality, and customer satisfaction. With a history of developing reliable and high-performance engine components, Cummins continues to be a trusted name in the industry, offering a wide range of products designed to meet the demanding requirements of heavy-duty applications.

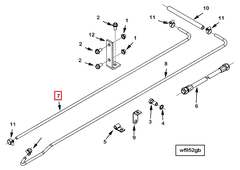

Role of Part 4095958 Water Transfer Tube in Engine Systems

The 4095958 is integral to the efficient operation of engine systems, particularly in cooling and thermal management. It facilitates the movement of coolant between various engine parts, ensuring heat is effectively dissipated and engine temperatures are maintained within optimal ranges.

Integration with Cooling System Components

- Heat Exchanger: The Water Transfer Tube connects to the heat exchanger, allowing coolant to flow through and absorb heat from the engine, preventing overheating and maintaining efficiency.

- Radiator: Coolant travels from the heat exchanger to the radiator via the Water Transfer Tube, releasing heat to the surrounding air before being recirculated back into the engine.

- Water Pump: The tube is often linked to the water pump, which drives the circulation of coolant throughout the engine system, ensuring a continuous flow.

Interaction with Protective Components

- Corrosion Resistor: The Water Transfer Tube works with corrosion resistors to protect metal components from coolant’s detrimental effects, maintaining the integrity of the tube and connected parts.

- Resistor: General resistors within the system help regulate the flow and temperature of the coolant. The Water Transfer Tube ensures these resistors function effectively by providing a consistent coolant supply.

Enhanced Thermal Management

By efficiently transferring coolant, the 4095958 plays a significant role in the overall thermal management of the engine. It ensures critical components, such as the cylinder head and engine block, remain at safe operating temperatures, enhancing performance and contributing to the longevity of the engine by reducing thermal stress on various parts.

Conclusion

The Cummins 4095958 Water Transfer Tube is a vital component in the cooling systems of heavy-duty trucks, ensuring efficient coolant transfer and thermal management. Its robust design, compatibility, and role in preventing engine overheating make it essential for maintaining engine performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.