This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

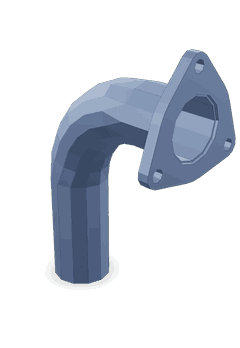

The Cummins 4098810 Water Transfer Tube is designed to facilitate the efficient transfer of coolant within the cooling system of heavy-duty trucks. This component ensures that the engine maintains an optimal operating temperature, which is essential for performance and longevity 3.

Basic Concepts of Water Transfer Tubes

A Water Transfer Tube is a conduit within a truck’s cooling system that directs coolant flow from the engine to the radiator and back. This process helps dissipate heat generated by the engine, maintaining a stable operating temperature and preventing overheating 1.

Purpose of the 4098810 Water Transfer Tube

The 4098810 Water Transfer Tube enhances the cooling system’s efficiency in heavy-duty trucks by ensuring a consistent and reliable flow of coolant. This helps maintain the engine’s temperature within the desired range, contributing to better performance and extending the engine’s operational life 3.

Key Features

This Cummins part is engineered with precision to meet the demanding requirements of heavy-duty applications. It is constructed from high-quality materials that offer durability and resistance to corrosion. The design ensures efficient coolant flow, minimizing restrictions and enhancing the cooling system’s performance. Its robust construction allows it to withstand the high pressures and temperatures typical in heavy-duty truck engines 2.

Benefits

Utilizing the 4098810 Water Transfer Tube improves the cooling efficiency of the truck’s engine, reducing the likelihood of overheating. This enhances the overall reliability of the cooling system, contributing to consistent engine performance. The tube’s durable construction ensures long-term operation without the need for frequent replacements, offering value and peace of mind to truck operators 3.

Installation Process

Installing the 4098810 Water Transfer Tube requires careful attention to detail to ensure proper function and longevity. The process involves disconnecting the old tube, cleaning the mounting area, and securely attaching the new tube. It is important to use the correct tools and follow manufacturer guidelines to avoid damage and ensure a leak-free connection. Proper installation is key to maintaining the efficiency of the cooling system 2.

Troubleshooting Common Issues

Common issues with the 4098810 Water Transfer Tube may include leaks or blockages. Leaks can often be traced to improper installation or wear and tear, while blockages may result from debris within the cooling system. Troubleshooting steps include inspecting the tube for signs of damage, ensuring all connections are secure, and flushing the cooling system to remove any obstructions. Addressing these issues promptly helps maintain the cooling system’s efficiency 1.

Maintenance Tips

Regular maintenance of the 4098810 Water Transfer Tube is vital for its continued efficient operation. This includes periodic inspections for signs of wear or damage, cleaning the tube and its connections to prevent blockages, and following the manufacturer’s guidelines for replacement intervals. Adhering to these maintenance practices ensures the cooling system remains effective, contributing to the engine’s performance and longevity 3.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the automotive industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s product offerings cater to various sectors, including heavy-duty trucks, where reliability and performance are paramount.

Water Transfer Tube (Part 4098810) in Cummins Engines

The Water Transfer Tube (Part 4098810) is a critical component in the cooling systems of various Cummins engines. This part is integral to the efficient operation of the engine’s cooling system, ensuring that the engine maintains optimal operating temperatures.

QSK60 and CM850 Engines

In the QSK60 and CM850 engines, the Water Transfer Tube is designed to facilitate the transfer of coolant between different parts of the engine’s cooling system. This ensures that heat is effectively dissipated from the engine’s core to the radiator, where it can be released into the atmosphere. The precise engineering of this tube is crucial for maintaining the integrity of the cooling system and preventing overheating, which can lead to engine damage 3.

MCRS Engines

For the MCRS engines, the Water Transfer Tube (Part 4098810) plays a similar role in the cooling system. It is engineered to handle the specific demands of these engines, which are often used in heavy-duty applications. The tube’s design allows for efficient coolant flow, which is essential for maintaining the engine’s performance under high-stress conditions. The durability and reliability of this part are critical, as the MCRS engines are frequently subjected to rigorous operating environments 2.

Grouping of Engines

The QSK60 and CM850 engines, while distinct in their applications, share a common design philosophy in their cooling systems. The Water Transfer Tube is a testament to this shared approach, as it is engineered to meet the stringent requirements of both engine types. The MCRS engines, on the other hand, represent a different segment of Cummins’ engine lineup, focusing on heavy-duty applications. Despite the differences in their intended use, the Water Transfer Tube is a common element that ensures the cooling systems of these engines function optimally 3.

Role of Part 4098810 Water Transfer Tube in Plumbing and Thermostat Housing

The Water Transfer Tube (part 4098810) is integral to the efficient operation of both plumbing and thermostat housing systems within an engine.

In the plumbing system, this component ensures a consistent flow of coolant between various engine parts. It connects to the water pump, radiator, and other coolant passages, facilitating the circulation necessary to maintain optimal engine temperature. The tube’s precise fit and durable construction prevent leaks and ensure that coolant is distributed evenly, which is essential for the longevity and performance of the engine 2.

Within the thermostat housing, the Water Transfer Tube plays a significant role in regulating the flow of coolant based on the engine’s temperature. It interfaces with the thermostat to control when coolant is allowed to flow through the radiator. This regulation helps in achieving the ideal operating temperature for the engine, enhancing both efficiency and reliability. The tube’s design allows for smooth transitions between open and closed states of the thermostat, ensuring that the engine neither overheats nor runs too cool 3.

Conclusion

The Cummins 4098810 Water Transfer Tube is a vital component in the cooling systems of heavy-duty trucks and various Cummins engines. Its role in ensuring efficient coolant flow and maintaining optimal engine temperature is crucial for the performance and longevity of the engine. Proper installation, regular maintenance, and prompt troubleshooting of common issues are essential for the continued efficiency of the cooling system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.