This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

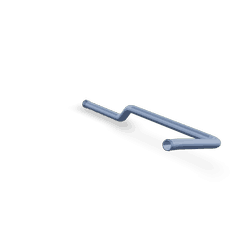

The Cummins 4100863 Water Transfer Tube is a component designed for use in commercial trucks. It serves a specific function within the engine cooling system, facilitating the efficient transfer of coolant between the engine and the radiator. This ensures that the engine operates within optimal temperature ranges, enhancing performance and longevity 1.

Purpose and Function

The Water Transfer Tube plays a role in the engine cooling system by enabling the movement of coolant. Coolant is circulated from the engine to the radiator where it is cooled, and then returned to the engine. This continuous cycle helps maintain engine temperature, preventing overheating which can lead to engine damage. The tube is positioned to connect key components within the cooling system, ensuring a smooth and uninterrupted flow of coolant 2.

Key Features

The Cummins 4100863 Water Transfer Tube is constructed from durable materials that are resistant to corrosion and high temperatures. It features secure connection points that are designed to withstand the pressures and vibrations typical in commercial truck operations. The design includes specific contours and pathways that optimize coolant flow, reducing the risk of blockages and ensuring consistent cooling performance 3.

Benefits

The use of the Cummins 4100863 Water Transfer Tube offers several advantages. It enhances coolant flow efficiency, which contributes to better engine temperature management. This, in turn, provides enhanced engine protection against overheating. The tube’s robust construction and design elements contribute to increased reliability, even under demanding operating conditions typical of commercial trucking.

Installation and Compatibility

Proper installation of the Water Transfer Tube involves ensuring that all connections are secure and that the tube is correctly aligned within the cooling system. It is important to follow manufacturer guidelines to prevent leaks and ensure optimal performance. The tube is designed to be compatible with specific engine models, ensuring a precise fit and function within the intended systems.

Maintenance and Troubleshooting

Regular maintenance of the Water Transfer Tube includes checking for signs of wear or damage, ensuring connections remain tight, and verifying that there are no leaks in the cooling system. Common issues may include blockages or corrosion, which can be addressed by cleaning or replacing the tube as necessary. Diagnostic tips involve monitoring engine temperature and coolant levels, which can indicate potential problems with the cooling system.

Performance in Various Conditions

The Cummins 4100863 Water Transfer Tube is engineered to perform effectively under a range of operating conditions. It maintains coolant flow efficiency in extreme temperatures, whether hot or cold, and under heavy loads. Its design ensures reliable performance during long-haul operations, contributing to the overall durability and efficiency of the engine cooling system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins is committed to innovation and quality, providing reliable products for various industries, including automotive. The company’s extensive product range and focus on technological advancement underscore its position as a leader in the industry.

Role of Part 4100863 Water Transfer Tube in Engine Systems

The 4100863 Water Transfer Tube is an essential component in the efficient operation of engine systems, particularly in those equipped with aftercoolers. This tube facilitates the movement of water between various components, ensuring optimal performance and longevity of the engine.

Integration with Plumbing Systems

In engine systems, the Water Transfer Tube is integral to the plumbing network. It connects to the water pump, which draws water from the reservoir. The tube then channels this water to critical areas within the engine that require cooling. This consistent water flow is vital for maintaining the engine’s temperature within operational limits, preventing overheating and potential damage.

Function in Aftercooler Water Circuits

The aftercooler is a device used to cool the compressed air from the turbocharger before it enters the engine’s combustion chambers. The Water Transfer Tube plays a significant role here by transporting water from the cooling system to the aftercooler. This water helps in dissipating the heat generated during the compression process, ensuring that the air entering the engine is at an optimal temperature. This not only enhances engine efficiency but also contributes to the overall reliability and performance of the engine.

Enhanced Engine Performance

By effectively managing the water flow within these systems, the Water Transfer Tube ensures that both the engine and the aftercooler operate at peak efficiency. This results in improved engine performance, reduced wear and tear, and extended maintenance intervals. The tube’s role in these processes underscores its importance in the intricate balance of engine component interactions.

Conclusion

The Cummins 4100863 Water Transfer Tube is a vital component in the engine cooling systems of commercial trucks. Its design and functionality contribute to efficient coolant flow, optimal engine temperature management, and overall engine reliability. Proper installation, regular maintenance, and understanding its role in various engine systems are crucial for maximizing the performance and longevity of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.