This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4100866 Water Transfer Tube is a component designed to facilitate the efficient transfer of coolant within the cooling system of heavy-duty trucks. Its role is integral to maintaining optimal engine temperature, ensuring the engine operates within safe thermal limits under various driving conditions.

Basic Concepts of Water Transfer Tubes

A water transfer tube is a conduit that allows coolant to flow between different parts of the engine cooling system. This system relies on the circulation of coolant to absorb heat from the engine and dissipate it through the radiator. Efficient coolant circulation is vital for preventing engine overheating, which can lead to reduced performance and potential damage 1.

Purpose of the Cummins 4100866 Water Transfer Tube

The Cummins 4100866 Water Transfer Tube specifically serves to transfer coolant between the engine and the radiator. This transfer is crucial for dissipating heat generated by the engine, ensuring that the coolant absorbs heat effectively as it circulates through the engine block and then releases this heat as it passes through the radiator.

Key Features

The Cummins 4100866 Water Transfer Tube is constructed from durable materials designed to withstand the high temperatures and pressures within the engine cooling system. Its design includes features that enhance performance, such as smooth internal surfaces to facilitate efficient coolant flow and robust connections to ensure a secure fit within the system. These attributes contribute to its effectiveness in heavy-duty applications.

Benefits

The use of the Cummins 4100866 Water Transfer Tube offers several benefits. It contributes to improved engine cooling efficiency by ensuring consistent and reliable coolant flow. Its durable construction enhances the overall reliability of the cooling system, making it suitable for the demanding conditions encountered by heavy-duty trucks. Additionally, its design helps maintain system integrity, reducing the risk of leaks and other cooling system failures.

Installation Considerations

Proper installation of the Cummins 4100866 Water Transfer Tube is crucial for its effective operation. Installation procedures should follow manufacturer guidelines, including the use of appropriate tools and ensuring all connections are secure. Attention to detail during installation helps prevent common issues such as leaks or improper coolant flow, contributing to the overall efficiency of the cooling system.

Common Issues and Troubleshooting

Common issues with the Cummins 4100866 Water Transfer Tube may include leaks or blockages, which can impede coolant flow and affect engine cooling efficiency. Troubleshooting these issues involves inspecting the tube and connections for signs of wear or damage, ensuring all fittings are secure, and checking for obstructions within the tube. Addressing these issues promptly helps maintain the cooling system’s performance.

Maintenance Tips

Routine maintenance of the Cummins 4100866 Water Transfer Tube is important for prolonging its lifespan and ensuring optimal performance. This includes regular inspections for signs of wear or damage, cleaning the tube and connections to remove any buildup that could impede coolant flow, and ensuring all connections remain tight. Adhering to these maintenance practices contributes to the reliability of the cooling system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves customers in approximately 190 countries and territories through a network of company-owned and independent distributor facilities and dealerships. The company’s reputation in the automotive and heavy-duty truck industry is built on its commitment to quality, performance, and customer satisfaction.

Role of Part 4100866 Water Transfer Tube in Engine Systems

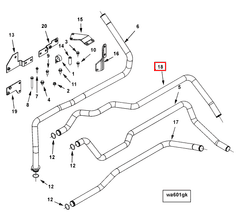

The Cummins 4100866 Water Transfer Tube is an integral component in the efficient operation of various engine systems, particularly in the context of aftercooler water systems and auxiliary cooling setups.

In the aftercooler water system, the Water Transfer Tube facilitates the movement of coolant from the aftercooler to the engine’s cooling system. This process ensures that the air entering the engine is adequately cooled, which enhances combustion efficiency and reduces the risk of overheating. The tube’s precise fit and secure connection to the aftercooler and engine components are essential for maintaining a consistent coolant flow, which is vital for the system’s overall performance.

Within the auxiliary cooling system, the Water Transfer Tube plays a significant role in distributing coolant to additional heat exchangers or radiators. This distribution helps manage the thermal load on the engine, especially under high-stress conditions or in extreme environments. The tube’s design allows for efficient coolant circulation, which is necessary for maintaining optimal engine temperature and preventing thermal damage.

In terms of plumbing, the Water Transfer Tube is often connected to various hoses, fittings, and valves that make up the coolant pathway. Its role in this network is to provide a reliable and leak-free connection between different components, ensuring that coolant is delivered where it is needed most. The tube’s material and construction are chosen to withstand the pressures and temperatures encountered in engine systems, contributing to the durability and effectiveness of the plumbing setup.

Conclusion

The Cummins 4100866 Water Transfer Tube is a critical component in the cooling systems of heavy-duty engines, ensuring efficient thermal management and maintaining optimal operating temperatures. Its durable construction, precise design, and reliable performance make it essential for the longevity and efficiency of engine systems.

-

Bennett, Sean. Modern Diesel Technology Light Duty Diesels. Cengage Learning, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.